5

Tank installation

Logano G334X – 6 720 811 237 (2014/05)

17

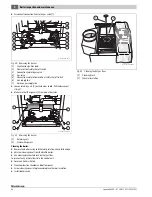

Fig. 22 Supply connection

[1]

Boiler

[2]

Safety valve

[3]

Supply manifold pipe (factory-installed)

[4]

90° elbow (¾ " NPT)

[5]

Supply connection

5.9

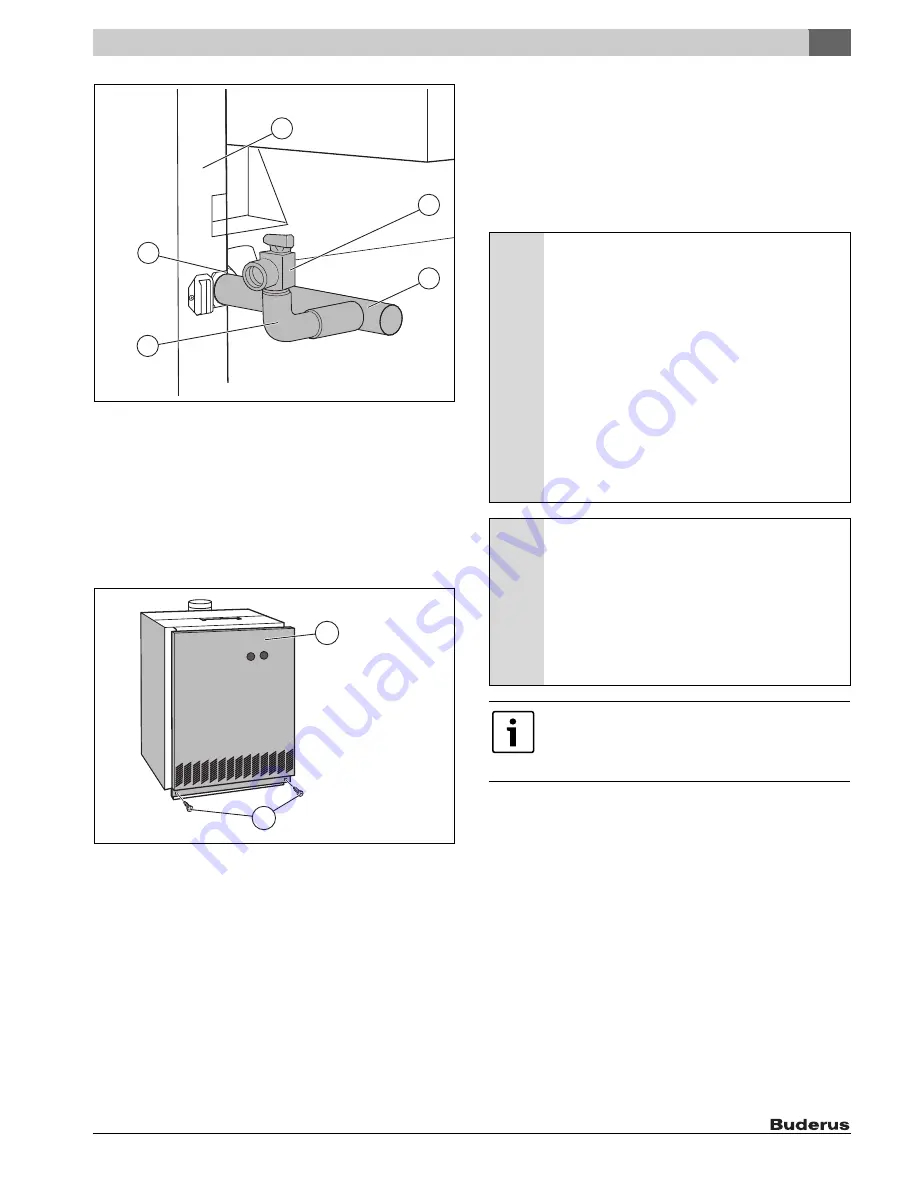

Installing front wall of boiler

▶ Hang front wall of boiler [1] from above, fold down

▶ Screw in locking screws [2] at the bottom of the front wall.

Fig. 23 Installing front wall of boiler

[1]

Front wall of boiler

[2]

Locking screws

5.10

Connecting the flue connector

5.10.1 Check openings for combustion air supply and venting

To ensure an adequate combustion air supply and venting of the heating

system, suitable measures must be taken in accordance with the

National Fuel Gas Code, NFPA 54 (ANSI Z223.1), Chapter 5.3, Air for

Combustion and Ventilation, and the local building codes. In Canada the

regulations in accordance with CAN/CSA B 149.1 and 2 Installation

Codes apply.

Total air supply from inside the building

Make sure that the installation room has two permanent air vents that

are connected to one or more other rooms. When calculating the cross-

sectional areas of the vent openings, the total burner output of all gas-

fired appliances in the connected rooms must be taken into account.

Each vent must have a minimum cross-section of one square inch per

1000 Btu/h (2200 mm

2

/kw) of the total burner output of all gas-fired

appliances inside the connected rooms. Make sure that the cross-

sectional area of each vent is at least 100 square inches (0.06 m

2

). One

of the vents must be no more than 12 inches (300 mm) from the ceiling

and the other no more than 12 inches (300 mm) from the floor of the

boiler room, measured from the outer edge of the vent opening.

The smallest dimension of all air intake and outlet openings must be not

less than 3 inches (80 mm).

1

2

3

4

5

6 720 806 028-17.1T

1

2

6 720 810 547-35.1T

NOTICE:

Risk of boiler damage and malfunctions due to

missing or inadequate openings for combustion air and

venting of the installation location!

Inadequate venting of the installation room may result in

excessive ambient temperatures. This can damage the

boiler.

Inadequate combustion air supply may cause

malfunctions.

▶ Make sure that air intake and outlet openings are not

closed off or their size reduced and that they are

adequately dimensioned.

▶ The boiler must not be operated until the obstruction

has been removed.

▶ Draw the owner's/operator's attention to any

deficiencies and the potential dangers.

NOTICE:

Risk of boiler damage due to dirty combustion

air.

▶ Never use cleaning agents containing chlorine and

never use halogenated hydrocarbons (as, for

example, contained in spray cans, solvents, cleaning

agents, paints and adhesives).

▶ Do not store or use these substances in the boiler

room.

▶ Avoid excessive dust accumulation.

If impurities in the combustion air are possible (e.g.

installation near swimming pools, dry cleaners or

hairdressing salons), sealed combustion is

recommended.

Summary of Contents for G334X

Page 38: ...10 Logano G334X 6 720 811 237 2014 05 38 Notes ...

Page 39: ...10 Logano G334X 6 720 811 237 2014 05 39 Notes ...

Page 40: ......