6

Placing the heating system in operation

Logano G334X – 6 720 811 237 (2014/05)

20

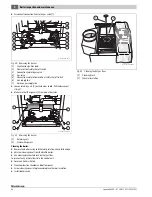

5.10.6 Electrically connecting the vent damper

▶ Disconnect the heating system from the power supply.

▶ Route the connection cable of the vent damper through the wiring

retainer behind the boiler and between the thermal insulation and

the jacket to the aquastat [1] on the front of the boiler.

Fig. 25 Electrically connecting the vent damper

[1]

Aquastat

▶ Connect vent damper to aquastat as shown in the wiring diagram.

6

Placing the heating system in operation

▶ Complete the commissioning report during this process

(

Chapter 6.8, page 26).

6.1

Testing the safety valve

The pressure relief valve must open and release pressure. If the safety

valve fails to release excess pressure, it must be replaced, because

otherwise system components may be damaged by excessive operating

pressure.

6.2

Making the heating system ready for operation

The burner and gas fittings unit integrated in the boiler have been tested

in the factory as described in detail in ANSI Z 21.13 and CSA 4.9 to

ensure safe operation of the heating system and to test specific

performance indicators.

1. Set the room thermostats to the lowest setting.

2. Inspect flue gas and combustion air piping and the openings for

combustion air supply and ventilation.

3. Fill heating system with water and bleed the complete system,

including the radiators.

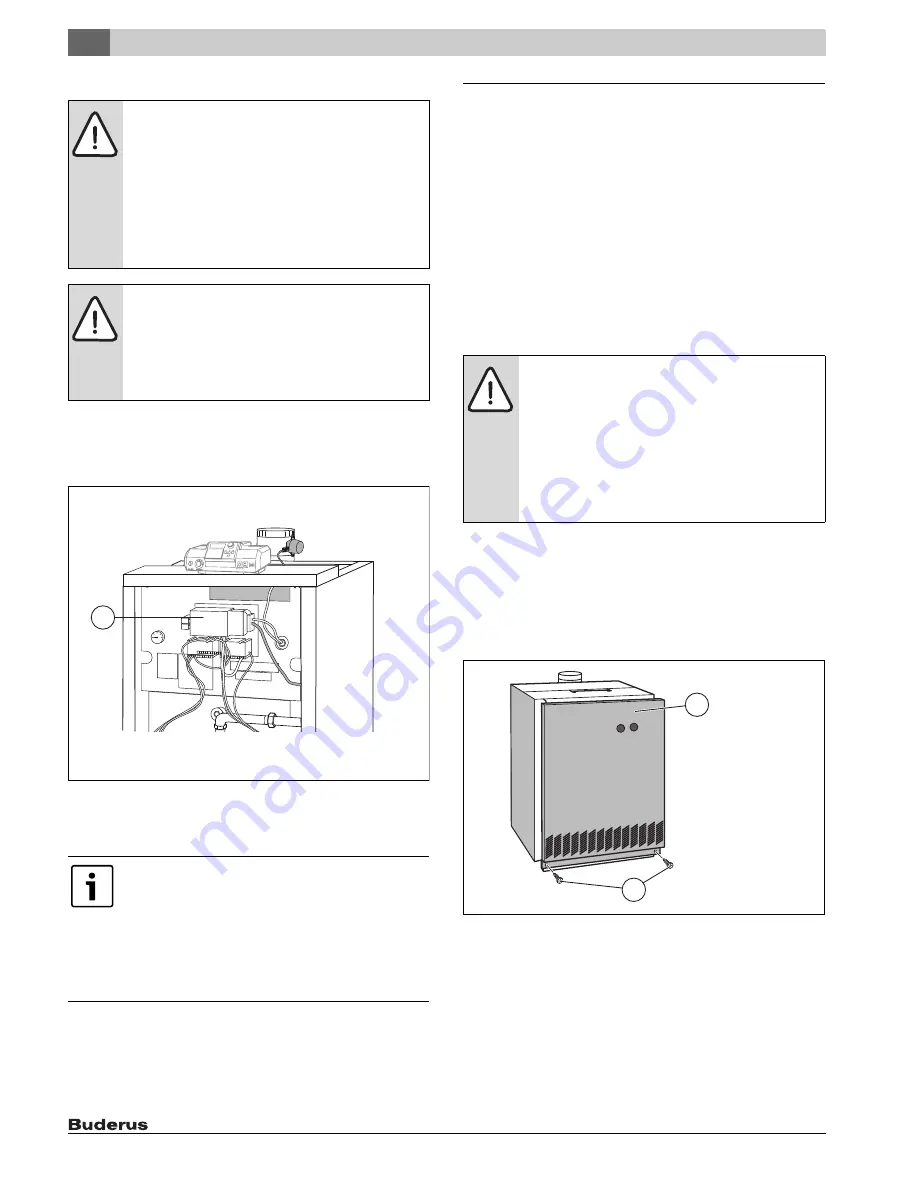

4. Unscrew the locking screws [2] at the bottom of the front wall of the

boiler [1], lift front wall of boiler, tilt it forward and remove it.

Fig. 26 Removing front panel of boiler

[1]

Front wall of boiler

[2]

Locking screws

DANGER:

Danger to life from electric shock!

▶ Only qualified electricians are permitted to carry out

electrical work.

▶ Before opening the appliance, disconnect it from the

power supply by means of the emergency shutoff

switch or the appropriate building fuse.

▶ Take measures to ensure that the heating system

cannot be accidentally reactivated.

▶ Please observe all installation instructions.

DANGER:

Fire hazard from hot boiler components!

Hot boiler components may damage electrical cables.

▶ Ensure that the electrical cables are not touching any

hot parts.

▶ Make sure that all cables are routed through the

conduits provided.

All connection points on the complete flue gas system

must be checked for correct installation and sealing

immediately after carrying out each of the installation

steps. The seams and connections must be checked for

gas leaks. Regulations require the complete flue gas

system to be checked at least once a year by a trained

and certified installer after installation and initial

operation.

1

6 720 810 547-33.1T

DANGER:

Risk of fatal injury from electric current when

appliance is opened up!

▶ Before opening the boiler:

Disconnect the heating system from the electrical

power supply by means of the emergency shutoff

switch or the appropriate building fuse.

▶ It is not sufficient just to switch off the controller.

▶ Take measures to ensure that the heating system

cannot be accidentally reactivated.

1

2

6 720 810 547-35.1T

Summary of Contents for G334X

Page 38: ...10 Logano G334X 6 720 811 237 2014 05 38 Notes ...

Page 39: ...10 Logano G334X 6 720 811 237 2014 05 39 Notes ...

Page 40: ......