- 12 -

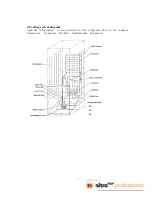

The location of the evaporator temperature sensor

always fixed on the suction tube as attached

(sometimes it fixed on the right middle of the

evaporator).

Take off the evaporator temperature sensor ,and

Measure the resistor , if sensor is bad ,change a new

one.

Meanwhile, measure the resistor of wire plug, If the

resistance

figure

shows

infinity,

that

means

connection between the main board and wire plug

have problem. the detail method as above.

The solution for “E3”problem:

According to above two principle, to check both above

◆

The common problem judgement method

Problem

Cause

Refrigerator can’t

start

1.1 Is the power cord connecting well

?

1.2 Is the power voltage too low

?

1.3 Is the sensor irrational setting?

1.4 Is the ambient temperature too low?

1.5 Is the circuit on power?

1.6 Is there some default in compressor

1.7 Is the refrigeration system blocked by ice or dirty, please stop the unit

and

restart after 10 minutes to see if the compressor can start.

Weak cooling effects

2.1 Is there any heat source around the refrigerator?

2.2 Is there enough space around the refrigerator for rejection of heat?

2.3 Is the setting of the temperature appropriate?

2.4 Is there too much food or overheating food in it?

2.5 Does there open the door frequently?

2.6 Is the door completely closed?

2.7 Does the gasket destroyed or distort?

2.8 Does the gas leak?

The unit can not stop

running

3.1 Is there any heat source around the refrigerator?

3.2 Is there enough space around the refrigerator for rejection of heat?

3.3 Is the setting of the temperature appropriate?

3.4 Is there too much food or overheating food in it?

3.5 Does there open the door frequently?

3.6 Is the door completely closed?

3.7 Does the gasket destroyed or distort?

3.8 Is the thermostat good operation?

3.9 Does the gas leak?

Ice up in the freezing

4.1 Is the setting of the temperature appropriate?