- 8 -

3

SERVICING

3.1

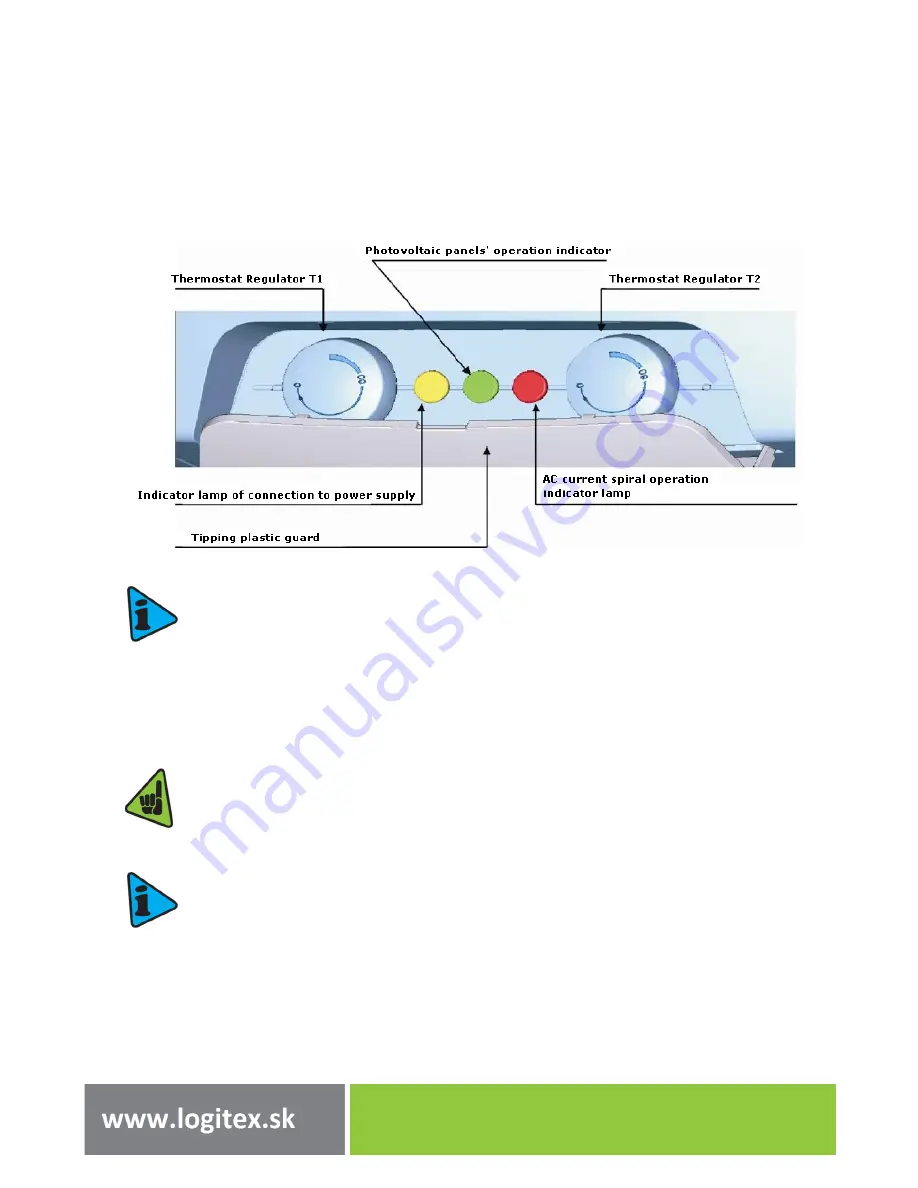

CONTROL PANEL

The heater tank is made of a steel plate and tested at 0.9 MPa of overpressure. The inside of the

tank is enamelled. A flange is welded onto the bottom of the tank with a flange lid screwed to it.

A sealing ring is inserted between the flange lid and the flange to ensure perfect tightness. There

are wells for the placing of heating, regulation and safety elements for water heaters in the

flange lid (heating element, thermostat sensor and thermal fuse). An anode rod is mounted onto

the M8 nut.

In combined versions, a heat exchanger is

welded

onto the pressure tank.

The anode rod is used as a secondary protection for the heater tank. Through its reaction with

water, it creates an environment that prolongs the lifetime of the tank. The design of the anode

and the material used comply with the standard EN 12438.

A thermometer, that transmits information on the temperature of water in the accumulation

heater, is installed in the top part of the heater.

The accumulator is insulated by means of polyurethane foam that ensures minimal heat losses.

Electric wiring is placed in the bottom part of the heater, under an easily removable guard.

Temperature of water can be set by thermostats within the range between 5°C and 74°C

according to the scale marked thermostat regulators.

Cold water inflow is indicated with blue, hot service water (the “HSW” hereinafter) outflow is

indicated in red. All external steel parts are protected against corrosion with a powder baking

paint; connecting pieces are metal plated.