31

PK1500

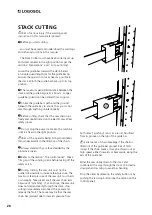

STACK CUTTER

CHANGING CUTTING

EQUIPMENT

After a while, the saw chain will lose its edge.

The saw chain can be easily removed for sharpening.

An electric grinder is recommended for sharpening,

but it is also possible to use a round saw chain file.

To ensure that the correct equipment is used, saw

chains, chain sprockets and guide bars should be

purchased from Logosol.

A new chain may need re-tightened after the first or

second cut.

Risk of cuts and burns.

Before commencing servicing, ensure that the

power is cut and that the saw chain is not rotating.

The chain may be hot. Always wear safety gloves.

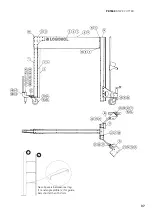

Removing the guide bar and chain:

When changing the chain, it is not necessary to

remove the bar nose guide.

1. Remove the chip duct.

2. Lay the chain around the guide bar and secure it

with tape so that it does not hang below the bar.

3. Place a support, e.g. a euro pallet, under the

guide bar.

4. Lower the motor unit until the guide bar is resting

on the support.

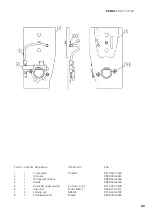

5. Set the chain tensioner (C) to its rearmost

position.

6. Loosen the guide bar nuts (A) and the cover plate

(B) that the oil pump sits on.

C

A

B

7. Lift off the guide bar.

It can be difficult to fit a new chain around the

sprocket because it is short. Chains stretch with use

and are then easier to fit.

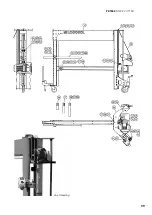

(Remove the chip duct.)

1. Lay the chain around the guide bar and secure it

with tape so that it does not hang below the bar.

2. During fitting, lower the motor unit until it rests

on a support, e.g. a euro pallet.

3. Check that the chain tensioner (C) is in its rear-

most position.

4. Rest the guide bar on the support.

5. Fit the bar nose guide to the T-profile (depending

on chain length, this can sometimes not be done

before the chain is tensioned).

6. Fit the guide bar on the guide bar bolts (A). Pull

the saw chain around the chain sprocket. Check

that the sprocket sits tight to the bearing housing

and that the collars of the guide bar bolts are in the

guide bar slot.

7. Push the cover plate (B) down over the bolts and

tighten the nuts (hand-tight).

8. Check that the guide bar, chain and bar nose

guide are correctly positioned.

9. Tighten the chain with the chain tensioner (C).

The chain should be tightened until it is in contact

with the underside of the guide bar.

10. Tighten the guide bar nuts (A).

11. Rotate the chain by hand and check that it runs

correctly around the guide bar. (wear safety gloves).

If it does not, the chain may be incorrectly installed

around the sprocket or it may be tightened too hard.

12. Raise the saw unit to its top position.and check

that the bar nose guide is in the correct position all

the way.

13. Refit the chip duct.

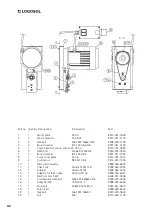

Summary of Contents for 0458-395-0603

Page 1: ...BRUKSANVISNING Ref no 0458 395 0603 LOGOSOL STACK CUTTER PK 1500 EN...

Page 11: ...11 PK1500 STACK CUTTER 1 2 M8x20 8 x 3 M6x20 10 x M6 4 x M8 8 x M6 14 x PK 1500...

Page 13: ...13 PK1500 STACK CUTTER 7 8 9 PK 1500...

Page 16: ...16 14 M10x25 M10x30 2 x 4 x M10 M10 2 x 2 x 15 M10 M10 4 x 2 x PK 1500...

Page 18: ...18 19 M6x120 12 x M6 M6 M6 M6 12 x 12 x 24 x 12 x PK 1500...

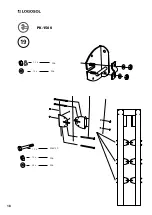

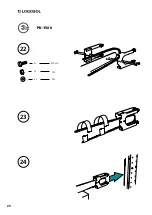

Page 20: ...20 22 23 24 M5 2x M5x20 2x M5 4x PK 1500...

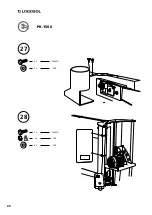

Page 22: ...22 27 28 M6x20 M6x20 2 x 2 x M6 M6 2 x 4 x M6 2 x PK 1500...

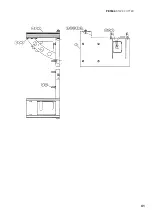

Page 39: ...39 PK1500 STACK CUTTER Line threading...

Page 41: ...41 PK1500 STACK CUTTER...

Page 49: ...Fiskaregatan 2 S 871 33 H rn sand SWEDEN Phone 46 611 18285 info logosol com www logosol com...