32

The guide bar pulls to one side

The angle of the guide bar should be adjusted so

that it is completely in line with the sawing direction.

The deviation may not exceed 0.1 mm on the bar

width.

If the chain has been damaged on one side, or filed

unevenly, it can run incorrectly. The chain will then

wear more on one bar rail, and if you continue to

saw the guide bar will wear unevenly. Even though

you replace the chain, an unevenly worn bar can

guide the chain incorrectly and, in addition, the new

chain can also be worn down.

An unevenly worn bar can be repaired. File the bar

rails so they are equally high, e.g. with an edge file

(SKU: 9999-000-0450), you can file the guide bar

rails to an even height.

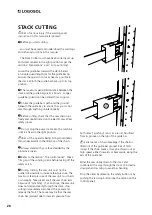

TROUBLESHOOTING –

CUTTING EQUIPMENT

The guide bar must not cut at an angle. Any

malfunctioning in this respect is most clearly

noticeable when the guide bar is raised after a

cut has been made. If the bar does not gently rest

against the cut surface, but pushes against it, or

moves away from it, there may be a fault with the

bar or the chain.

Causes of malfunctioning of the cutting equipment:

1. One cause of problem when using the Stack

Cutter is that you have a dull chain.

2. The chain may have been damaged on one side,

e.g. by a metal object in the wood. The chain will

still cut, but will pull to one side.

3. The chain has been filed incorrectly. The cutters

on one side have been filed down less than those on

the other. To get a more even result, try to have the

same working position when filing the right and left

sides of the chain. A few teeth that are damaged

or completely lost after cutting through a nail

does not normally have a noticeable effect on the

performance of the chain.

4. When precision decreases after a period of

problem-free cutting, guide bar wear is almost

always the cause.

Another more common reason for the guide bar

pulling askew, is that it is worn out so that the drive

links touches the bottom in the track of the guide

bar and the chain loses the support provided by the

bar rails. This is shown on the chain by the tip of the

drive link becoming worn.

Test the chain oil with your fingers

In order for the chain oil to work well it must

be viscous and thready. When you place a drop

between the thumb and the index finger and then

open them, long threads should form. If only 2–3

threads form, the oil’s adhesion is insufficient and

the oil will be thrown off at the tip of the guide

bar. We recommend Logosol’s high-performance

vegetable chain oil for chain sawmills (SKU: 0718-

000-1010, 10 litres)

The oil flow is set by a screw on the oil pump. Flow

is set to maximum at the factory and must not be

altered.

Summary of Contents for 0458-395-0603

Page 1: ...BRUKSANVISNING Ref no 0458 395 0603 LOGOSOL STACK CUTTER PK 1500 EN...

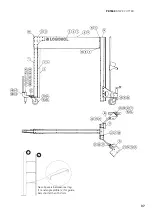

Page 11: ...11 PK1500 STACK CUTTER 1 2 M8x20 8 x 3 M6x20 10 x M6 4 x M8 8 x M6 14 x PK 1500...

Page 13: ...13 PK1500 STACK CUTTER 7 8 9 PK 1500...

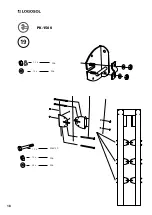

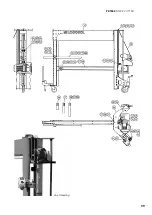

Page 16: ...16 14 M10x25 M10x30 2 x 4 x M10 M10 2 x 2 x 15 M10 M10 4 x 2 x PK 1500...

Page 18: ...18 19 M6x120 12 x M6 M6 M6 M6 12 x 12 x 24 x 12 x PK 1500...

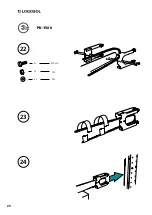

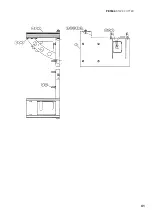

Page 20: ...20 22 23 24 M5 2x M5x20 2x M5 4x PK 1500...

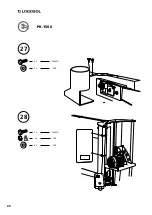

Page 22: ...22 27 28 M6x20 M6x20 2 x 2 x M6 M6 2 x 4 x M6 2 x PK 1500...

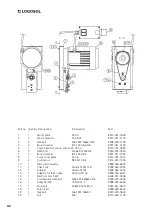

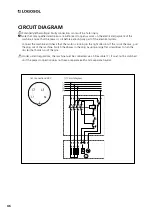

Page 39: ...39 PK1500 STACK CUTTER Line threading...

Page 41: ...41 PK1500 STACK CUTTER...

Page 49: ...Fiskaregatan 2 S 871 33 H rn sand SWEDEN Phone 46 611 18285 info logosol com www logosol com...