35

PK1500

STACK CUTTER

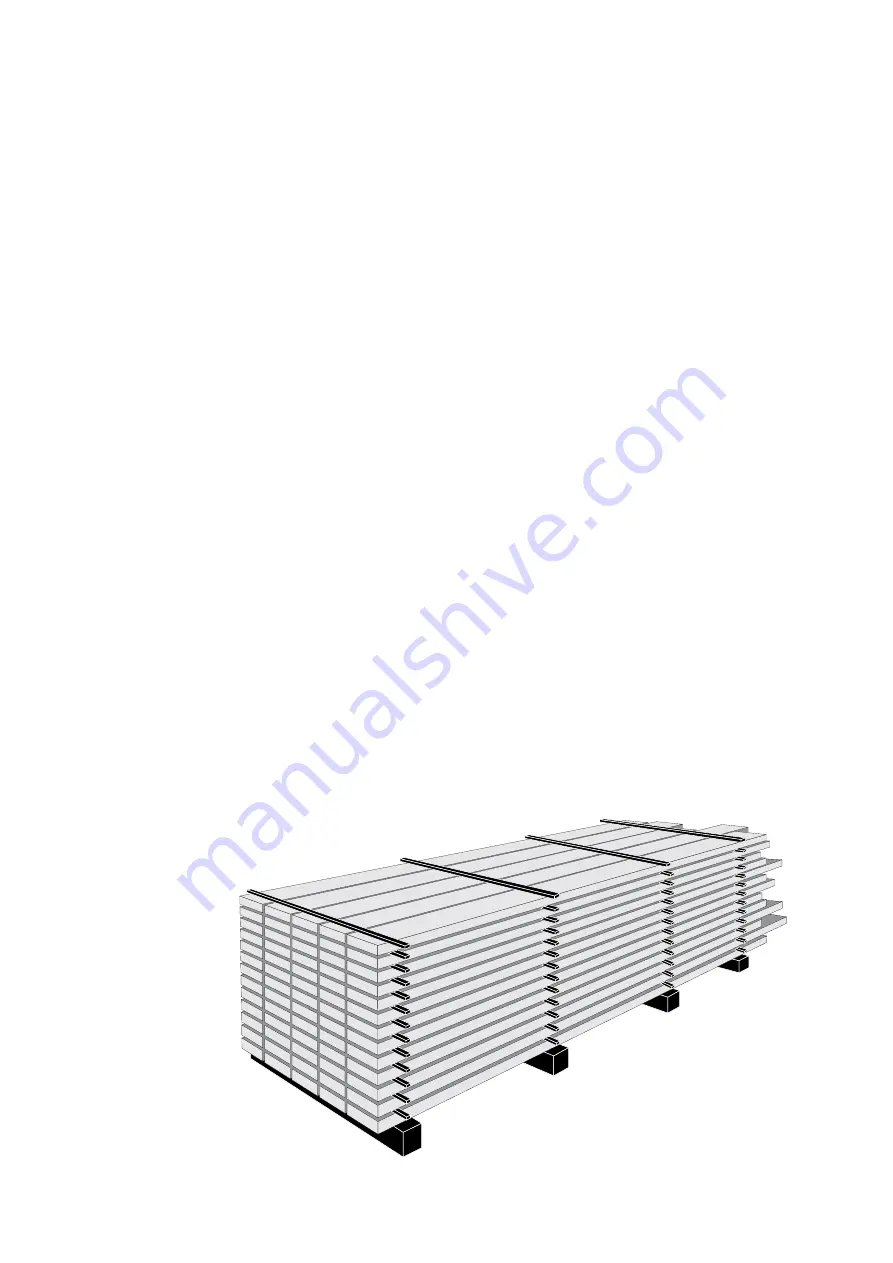

Once the wood is sawn it must be dried. If this is not

done in the right way, then there is a danger it will

be damaged by fungal rot.

The best time for outdoor drying is in the spring.

The relative humidity of the air is very low and the

wood will dry in a couple of weeks.

Cut some supportive blocks in the length that

corresponds to the width of your pile, ideally larger

pieces, e.g. 5’’5, to raise the wood from the ground,

which should also be dry, level and free of growth.

The spacing should not exceed 1 m and should lie

level and in line with each other.

Cut spacers or drying sticks in the same length as

the supportive blocks.They should be of the same

thickness (1x1’’ or 1x2’’) and dry. (You can get

material for these by making an extra cut when

edging your boards.)

Place the first row of boards on the underlying

surface. The boards are to be of the same thickness

and be positioned a few centimetres apart. Then

place spacers on the boards (in the same positions

as the underlying supportive blocks) before the

next layer is laid. It is important to place the spacers

exactly over each other, to keep the boards from

warping or bending.

The higher you pile the boards, the better pressure

there is on the lower boards. Place roofing of plastic,

metal sheeting or masonite over the top to provide

protection from rain, but leave the sides open. Put a

weight of some sort on the roof to put pressure on

the top boards.

If the wood is to be used for fine joinery, it should

be stored in a heated room for another 3-4 weeks

(longer for thicker dimensions) or be dried in a wood

drying kiln for a perfect result.

It is possible to use undried wood in some

constructions, but it must be kept in mind that the

width and height will shrink 5%. Wood also shrinks

around 0.3% in length, but this can usually be

disregarded. In order to avoid rot, you should not

enclose undried wood in a way that makes it hard

for air to circulate. One further tip: Do not drive two

nails next to each other as the board will probably

crack in the middle when it dries out. Drive one nail

and wait with the second until the wood has dried.

One example of where you should use undried

wood is when building log structures. In such a

situation, a heavy wall is a plus, as is the possibility

that the logs still can be shaped when they are

pressed against each other.

LOGOSOL also has electric

wood drying kilns for

preparation of fine joinery

timber.

MATERIAL DRYING

Summary of Contents for 0458-395-0603

Page 1: ...BRUKSANVISNING Ref no 0458 395 0603 LOGOSOL STACK CUTTER PK 1500 EN...

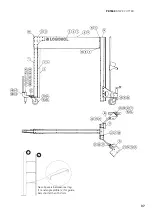

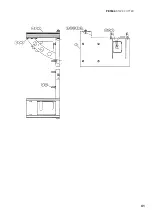

Page 11: ...11 PK1500 STACK CUTTER 1 2 M8x20 8 x 3 M6x20 10 x M6 4 x M8 8 x M6 14 x PK 1500...

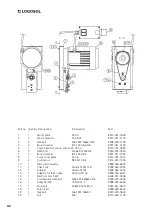

Page 13: ...13 PK1500 STACK CUTTER 7 8 9 PK 1500...

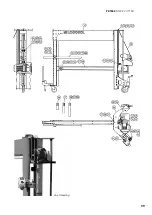

Page 16: ...16 14 M10x25 M10x30 2 x 4 x M10 M10 2 x 2 x 15 M10 M10 4 x 2 x PK 1500...

Page 18: ...18 19 M6x120 12 x M6 M6 M6 M6 12 x 12 x 24 x 12 x PK 1500...

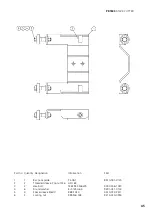

Page 20: ...20 22 23 24 M5 2x M5x20 2x M5 4x PK 1500...

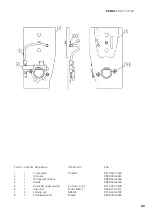

Page 22: ...22 27 28 M6x20 M6x20 2 x 2 x M6 M6 2 x 4 x M6 2 x PK 1500...

Page 39: ...39 PK1500 STACK CUTTER Line threading...

Page 41: ...41 PK1500 STACK CUTTER...

Page 49: ...Fiskaregatan 2 S 871 33 H rn sand SWEDEN Phone 46 611 18285 info logosol com www logosol com...