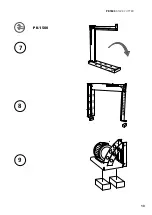

5

PK1500

STACK CUTTER

SAFETY INSTRUCTIONS

During operation

:

Do not start cutting until the steps in the section

”Preparations” on page 26 have been carried out.

Never start the stack cutter if the guide bar is not in

its top position and covered by the fixed bar guard.

Never stick hands or tools under any guards or in the

cutting path of the guide bar.

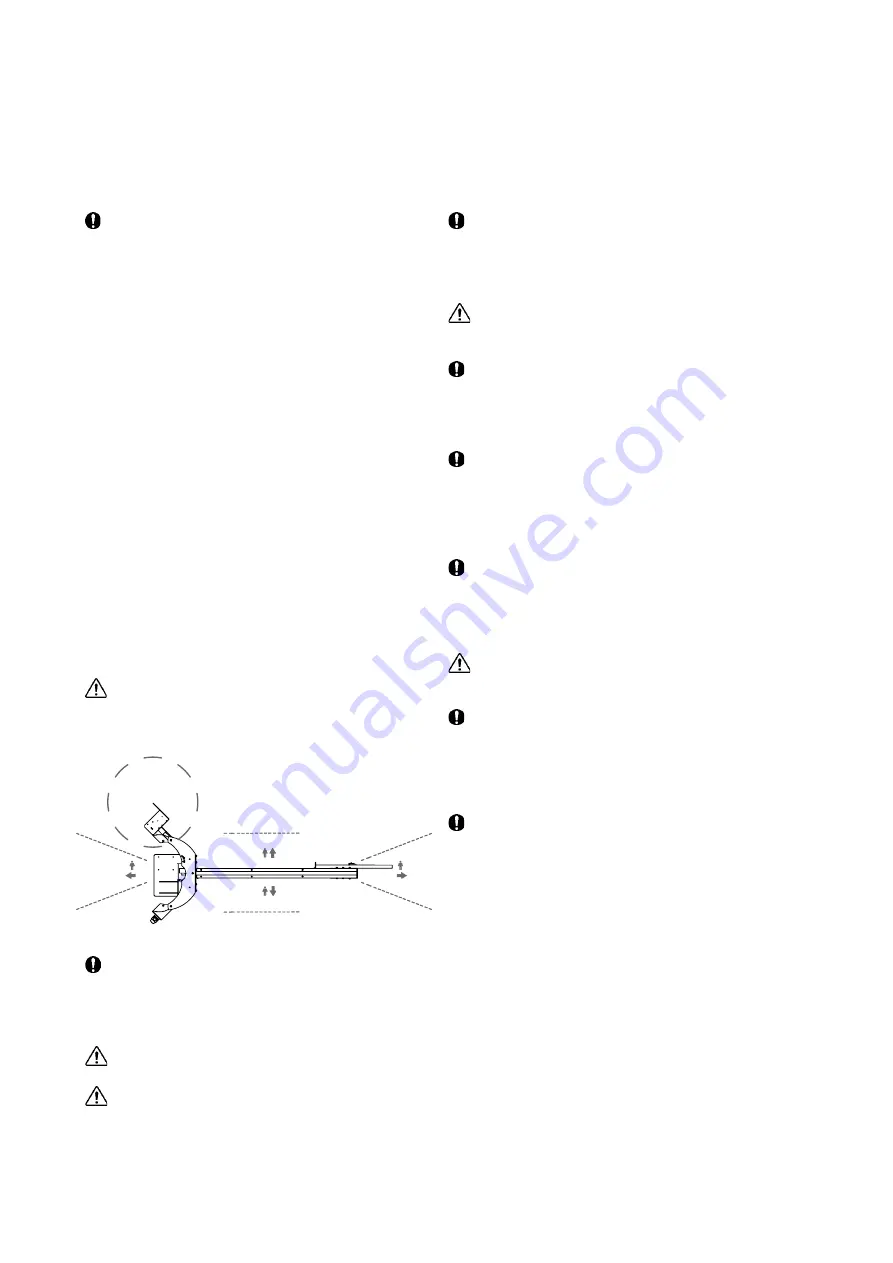

Always stand with your face shielded by the

protective screen. When end trimming, the chain

can throw blocks of wood in the operator’s

direction.

On the same axis as the guide bar, with a 20

degree deviation to either side, the safe distance

“in front of” and “behind” the machine is 8

m (see the illustration). This also applies to the

operator. Besides the operator (shown as “Op” in

the illustration), no one may stand within 4 metres

of the machine’s sides while it is operating. The

illustration below shows a bird’s-eye view of the

machine. During operation, the operator must stay

within the indicated area behind the control panel.

The operator must not stretch his/her arms or legs

outside this area.

Risk of chain throw-off if the chain breaks.

Respect the safe distance!

Before releasing the winch safety catch, take a

firm grip of the winding crank. Except when the saw

unit is to be lowered, the safety catch should always

be on.

Risk of burns when changing the chain.

Cutting equipment can be hot after use.

A chip extractor (min. 700 m

3

/h) must be

connected during operation. Be aware of the risk

of breathing in dust. Saw outdoors or ensure good

ventilation.

Even people outside the safe distance may still

require ear protectors. Outdoors, the safe distance

for harmful noise is around 15 m. Ensure that no

one without ear protectors is exposed to sounds

above 70 dB(A).

Use non-toxic, vegetable, saw chain oil to

lubricate the chain.

Risk of unintentional start-up and electric

shock.

In this manual, the instruction ”cut the power”

always

means unplug the power cable at the

control panel, hang it up so that neither the plug

nor the cable can be damaged, and ensure that

the chain has stopped.

Cut the power

- Before touching the chain in any way.

- Before attempting to free a jammed chain.

- Before servicing or other intervention involving the

guide bar, belt guard or electrical system.

- Before moving the machine.

- If the machine is to be left unattended. Also ensure

that no unauthorised person can start the machine.

- After fitting a chain, ensure that it runs freely

before plugging the cable into the control panel.

Other safety instructions:

The machine must not be modified or added to. Use

only parts supplied by LOGOSOL. After servicing, the

machine must be restored to its original condition.

Risk of being hit by the winding crank.

Risk of the saw unit being lowered

unintentionally.

4M

4M

Operator

8M

8M

Summary of Contents for 0458-395-0603

Page 1: ...BRUKSANVISNING Ref no 0458 395 0603 LOGOSOL STACK CUTTER PK 1500 EN...

Page 11: ...11 PK1500 STACK CUTTER 1 2 M8x20 8 x 3 M6x20 10 x M6 4 x M8 8 x M6 14 x PK 1500...

Page 13: ...13 PK1500 STACK CUTTER 7 8 9 PK 1500...

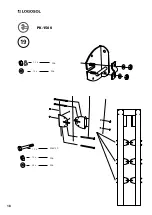

Page 16: ...16 14 M10x25 M10x30 2 x 4 x M10 M10 2 x 2 x 15 M10 M10 4 x 2 x PK 1500...

Page 18: ...18 19 M6x120 12 x M6 M6 M6 M6 12 x 12 x 24 x 12 x PK 1500...

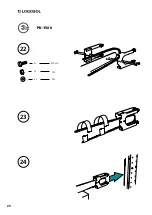

Page 20: ...20 22 23 24 M5 2x M5x20 2x M5 4x PK 1500...

Page 22: ...22 27 28 M6x20 M6x20 2 x 2 x M6 M6 2 x 4 x M6 2 x PK 1500...

Page 39: ...39 PK1500 STACK CUTTER Line threading...

Page 41: ...41 PK1500 STACK CUTTER...

Page 49: ...Fiskaregatan 2 S 871 33 H rn sand SWEDEN Phone 46 611 18285 info logosol com www logosol com...