7

PK1500

STACK CUTTER

End trimming with Logosol’s Stack Cutter

Note where the operator is standing, the position

of his hands, that the guide bar nose guard is

pushed towards the stack, that the stack stands

firmly on flat ground and that it is properly

strapped.

Max.

0.2m/sec.

Max.

0.2m/sec.

Thanks to its wheels, the STACK CUTTER can be

easily moved when required. Whenever possible, the

STACK CUTTER should be moved in the longitudinal

direction of the guide bar (i.e. not sideways). If

the STACK CUTTER is being moved more than a

short distance, the motor unit must be lowered to

its bottom position. The risk of tipping increases

considerably if the STACK CUTTER is moved sideways

(right/left). The floor over which the STACK CUTTER

is moved must be smooth and free from gravel and

anything else that can make the surface uneven.

Cut the power before moving the Stack Cutter.

Risk of tipping! The Stack Cutter may only be

moved on its wheels when the surface is smooth

and even.

Risk of tipping! The maximum permitted speed

when moving sideways is 0.2 m/sec. (1 m in 5 sec.).

When moving the machine, pay particular

attention to ensuring that the control panel does not

hit any obstacles.

When the machine is being moved, he winding

crank safety catch must always be on..

The Stack Cutter can easily be moved using a crane,

tractor or other equipment suitable for this purpose.

Use approved lifting straps/lifting chains. The Stack

Cutter has a lifting eye at the top of the rear leg. On

the motor-side, thread the straps or chains between

the handle bars and the guide rail.

SETTING UP

Read the entire manual and, before using the

machine, familiarize yourself with all the machine

functions and settings.

Inspect the Stack Cutter immediately on

reception. Any transport damage must be notified

immediately to the freight company.

Position the Stack Cutter on an even surface. Using

the crank on the adjustable wheel, adjust the

machine so that it is level and stable.

Connect the chip extractor hose and secure it with

hose clamps both at the the machine end and at the

extractor end.

Ensure that the lighting is first-class. Fit a powerful

light above the machine.

Check that all bolts are firmly tightened. Check that

the saw chain runs freely and unobstructed on the

guide bar. Check that the chain has been tensioned

(see p.31).

MOVING THE STACK CUTTER

Summary of Contents for 0458-395-0603

Page 1: ...BRUKSANVISNING Ref no 0458 395 0603 LOGOSOL STACK CUTTER PK 1500 EN...

Page 11: ...11 PK1500 STACK CUTTER 1 2 M8x20 8 x 3 M6x20 10 x M6 4 x M8 8 x M6 14 x PK 1500...

Page 13: ...13 PK1500 STACK CUTTER 7 8 9 PK 1500...

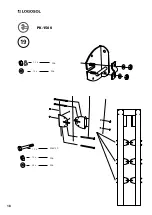

Page 16: ...16 14 M10x25 M10x30 2 x 4 x M10 M10 2 x 2 x 15 M10 M10 4 x 2 x PK 1500...

Page 18: ...18 19 M6x120 12 x M6 M6 M6 M6 12 x 12 x 24 x 12 x PK 1500...

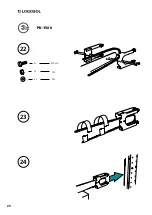

Page 20: ...20 22 23 24 M5 2x M5x20 2x M5 4x PK 1500...

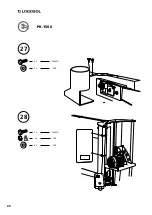

Page 22: ...22 27 28 M6x20 M6x20 2 x 2 x M6 M6 2 x 4 x M6 2 x PK 1500...

Page 39: ...39 PK1500 STACK CUTTER Line threading...

Page 41: ...41 PK1500 STACK CUTTER...

Page 49: ...Fiskaregatan 2 S 871 33 H rn sand SWEDEN Phone 46 611 18285 info logosol com www logosol com...