55

B1001

PROBLEM/SYMPTOM

PROBABLE CAUSE

SOLUTION

The blade quickly loses its sharpness

• Dirty logs

• The blade is worn out

• Avoid dragging the logs over the ground.

• Debark the log where the blade is going to cut.

• Square the logs before cutting boards, to

minimize the cuts into bark.

• Replace the blade with a new one.

Wavy cuts

• Dull blade

• The feed speed is too high

• The feed speed is too low

• Sawing through a partly frozen log

• Resharpen the blade.

• Lower the feed speed.

• Increase the feed speed.

• Let the log fully thaw or fully freeze before

sawing it.

TIP:

Do not use a slower sawing speed

when the blade is entering the log, but cut into

the log end with the same sawing speed you are

planning to have for the rest of the cut.

The blade dives or rises when sawing

• Insufficient blade tension

• The feed speed is too high

• The blade is damaged

• The blade does not track correctly on the band

wheels

• Increase the blade tension.

• Lower the feed speed.

• Replace the blade with a new one.

• Install the blade correctly and adjust the

tracking.

Blade breakage

• The blade is worn out

• Dull and/or incorrectly installed blade

• The blade tension is too tight

• The blade guide rollers are not aligned with the

band wheels

• Worn band wheel belts. This makes the blade

running directly on metal

• Replace the blade with a new one.

• Resharpen the blade.

• Reduce the blade tension.

• Adjust the blade guides.

• Replace the belts on the band wheels with new

ones

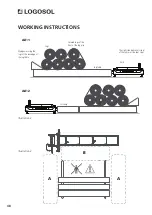

Uneven board thickness

• The log bed flexes due to insufficient support

• Support the rails/log bed as outlined in the

instructions in this manual

The blade does not track correctly and slips off

the band wheels

• The band wheels are incorrectly adjusted

• Worn band wheel belts

• Adjust the band wheels as outlined in the

instructions in this manual

• Replace the belts with new ones

The blade does not cut

• The blade is installed backwards

• Remove the blade and turn the blade inside out

and reinstall it.

• When the sawmill is powered by an electric

motor, check that the motor is running in the

correct direction. If not: Reverse the phase of the

electric motor.

The blade does not slacken after releasing the

blade tension with the T-handle

• The blade tension assembly is sticking

• Push the T-handle inwards.

The sawhead is stiff when raised or lowered

• The vertical guides are too tight

• The sawhead lifting winch drum is dry

• Lubricate with silicone and, if necessary, loosen

them slightly.

• Lubricate with Superflo.

The sawhead is rattling when going down

• The rails are not level and cause the saw bogie to

twist

• Level the rails as outlined in the instructions in

this manual.

The blade overheats during operation

• The water tank is empty

• The water valve is closed

• Refill with water.

• Open the water valve.

The engine does not start

• The ignition key is in the ”OFF” position

• The emergency stop button is pushed in

• The interlock safety switch on the blade guards is

disconnected

• Turn the ignition key to the ”ON” position.

• Reset the emergency stop.

• Check the working order of the interlock safety

switch.

TROUBLESHOOTING