min. max.

0

1

A

Seite 12

14. Operation

14. Operation

Accessories supplied by the manufacturer

to ensure a safe operation of the appliance, it comes with a grate lifter and a

cleaning brush.

Closing the heating door

the door of the thermoInsert is self-closing and self-locking. to open the hea-

ting door, press the integrated release button fully while pulling on the door

handle. When closing the heating door make sure that it engages with an au-

dible click.

Check:

It must not be possible to open the door simply by pulling

on the door handle.

opening the fuel drawer

the fuel drawer is equipped with a „tip-on“ catch; all it takes is a gentle push

on the front of the fuel drawer and the drawer opens

(Figure 13)

. to close the

drawer, gently push the front of the fuel drawer again until the lock engages.

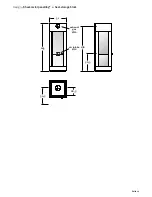

Adjustment of the air supply

the air supply required for combustion, which is taken from the bottom through

the grate into the combustion chamber, is adjusted by using the air slider in the

front panel

(Figure 14)

. this enables the required temperature in the combusti-

on chamber to be reached faster during the initial heating-up phase.

position 0:

the slider is closed, no primary air is supplied.

position 1:

the slider is opened, maximum supply of air, especially necessary

during the heating-up phase.

position A:

Heat-up position, use it only for heating-up and when adding fuel.

to do this, open the fuel drawer and pull out the slider fully. Once the heating-

up is completed (approx. 10 minutes), push the air slider into „position 1“ by

closing the fuel drawer or move it into position „0“ by hand.

Adjusting the supply of secondary air

the supply of secondary air (combustion air flowing from the top, over the

fuel) results in combustion appropriate for the fuel being used, resulting in

low-pollution emissions. part of the secondary air “washes down” across the

glass front. this air wash system ensures an unobstructed view of the flames.

the secondary air is controlled with the slider which is located above the fire-

box door

(Figure 15)

Wird der Hebel in richtung links bewegt, verringert sich die zuströmende se-

kundärluftmenge, in richtung rechts vergrößert sie sich.

See Air supply settings on page 13

Air wash system

the air wash system is very important both for the cleanness of the viewing

window and for providing secondary air that gives low-pollution combustion.

the air “washes down” across the glass front, flowing towards the combustion

chamber where it contributes to the combustion. this gives the best possible

cleanness of the window.

please note the following factors with regard to a clean window:

1. optimum chimney draught

For the air supply the chimney draught and the length of the supply

line play a decisive role. Certain weather conditions, especially between

seasons, can have a detrimental impact on the chimney draught.

2. dry, suitable fuel

use only dry wood (residual moisture max. 10-15 %). resinous wood has

a negative effect on the cleanness of the window. Do not burn painted,

impregnated or other similarly treated wood. Do not burn bark, particle

board or other waste.

3. Correct operation

remove ash at regular intervals, however, at the latest when the ash heap

has reached the air outlets in the ash pan. Only add the amount of fuel

that is necessary to generate the required heat.

4. Correct air supply setting

Fully open the combustion air supply.

If dirt still forms on the glass, it can be removed with a special glass cleaner for

chimney and oven windows when the appliance has cooled down. For further

details see MaIntenanCe anD Care.

Figure 13

Figure 14

Figure 15