Installation

Mounting a Detector Head onto a Conveyor

Introduction

Loma Systems have been manufacturing metal detector systems for many years and our current

conveyor design incorporates this wealth of experience. There are a number of integration rules that

have to be followed when fitting a new detector head to an existing or third party conveyor to attain

optimal performance and avoid nuisance triggering.

Basic Rules

1.

The conveyor must be substantial and of welded

not bolted

construction.

2.

The conveyor must have a means of height adjustment to level it to any infeed or outfeed

conveyor systems and also to take out any unevenness of flooring. This is to provide conveyor

stability.

3.

No fixed metal is allowed nearer to the detector aperture than a distance of 1.5 times the smaller

of the two aperture dimensions.

4.

No moving metal is allowed nearer to the detector aperture than a distance of 3 times the smaller

of the two aperture dimensions.

5.

The detector head must be mounted on the conveyor using the supplied mounting kit.

6.

The conveyor belt must be of a non metallic construction. The joint if applicable shall be heat

sealed or vulcanised. Angled joints are preferred where possible, as are finger joints for thicker

belts. Where modular belts are used, joining rods must be non metallic.

7.

Rollers should be of a substantial construction to prevent bowing and crowned where applicable

to help belt tracking on non modular belting.

8.

Rollers can be PVC coated steel or aluminium or manufactured in a good quality stainless steel.

9.

Rollers must be insulated from the main conveyor frame on at least one end to prevent the

formation of eddy current loops as these can cause the detector to false trigger.

10.

The conveyor belt must be supported through the detector aperture by a non metallic support

such as a phenolic plastic or nylon strips. Whatever is used, it must be strong enough to support

the intended product and not bow under the product weight.

11.

Electrical interference: The reject relay usually switches inductive loads such as motor starter

contactors and solenoid valves for air operated rejects. Its important that suitable suppressors

are fitted to these devices.

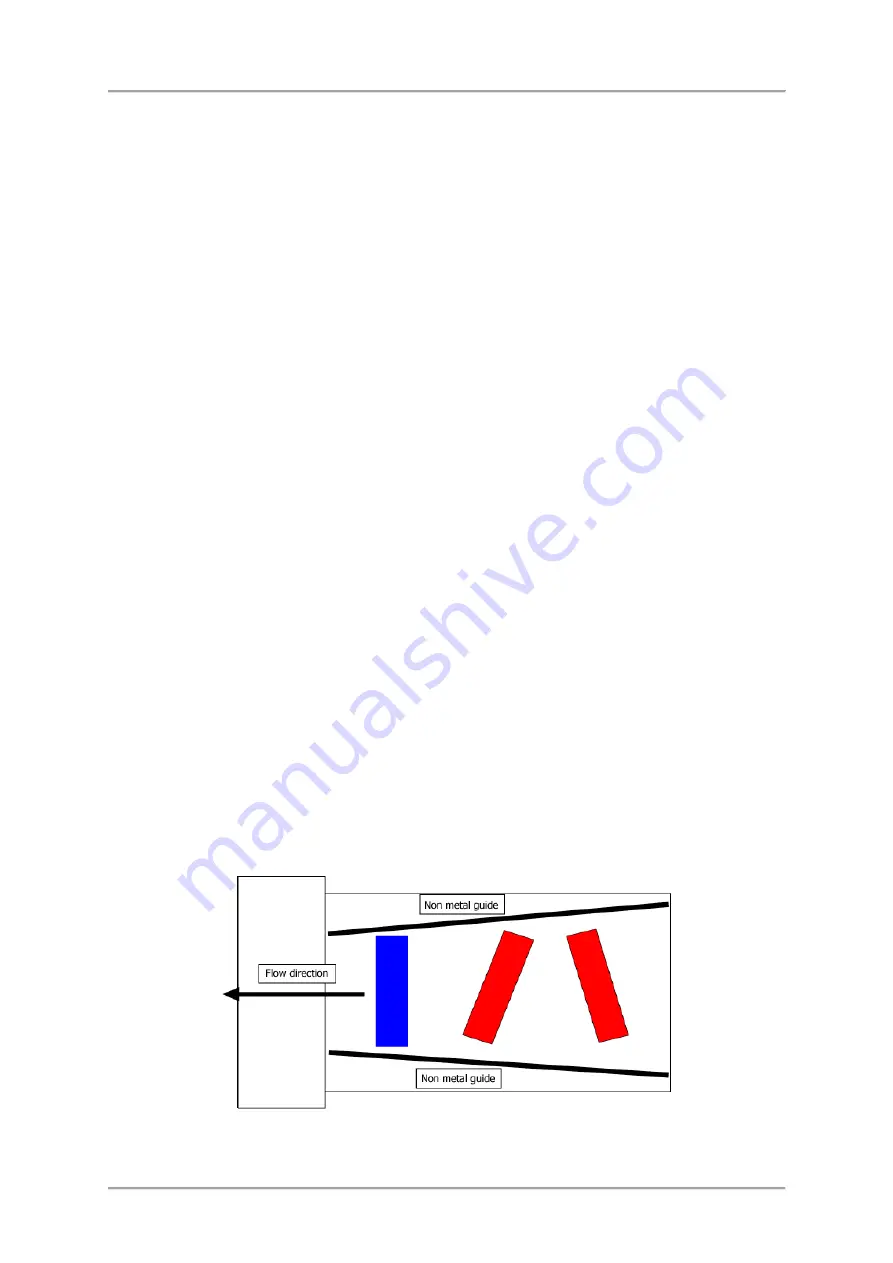

12.

Pack presentation: Consistent pack presentation is important to ensure optimal detection

performance. Non Metal guides should be fitted to make sure that products do not randomly twist

as they pass through the aperture. In the diagram below, where blue is good and red is bad, you

can see that good guiding should present products correctly.

34

Summary of Contents for IQ3

Page 2: ......

Page 10: ......

Page 26: ......

Page 43: ...Installation 33 ...

Page 60: ...Installation THIS PAGE IS INTENTIONALLY LEFT BLANK 50 ...

Page 70: ...About the Metal Detector Range THIS PAGE IS INTENTIONALLY LEFT BLANK 60 ...

Page 74: ...Getting Started IQ3 Dual Line Display Menu Map 64 ...

Page 116: ...Operating Instructions THIS PAGE IS INTENTIONALLY LEFT BLANK 106 ...

Page 140: ...Maintenance THIS PAGE IS INTENTIONALLY LEFT BLANK 130 ...