63

COMPILER TECO/ATL

REG. CODE

1-5302-296

MODEL N°

50510

DATE OF ISSUE

01.89

REVISION

02

ENDORSED

DATE

17.04.2003

168

167

g/kW.H

268÷275

251÷265

238÷251

247÷257

247÷257

265÷279

258÷272

238÷251

258÷272

251÷265

245÷254

245÷254

245÷254

g/CV. h

197÷202

185÷195

175÷185

182÷189

182÷189

200÷209

190÷200

175÷185

190÷200

185÷195

180÷187

180÷187

180÷187

11LD625-3

11LD625-3

11LD625-3

11LD625-3

11LD625-3

11LD535-3

11LD535-3

11LD535-3

11LD626-3

11LD626-3

11LD626-3

11LD626-3

11LD626-3

CV

N 38

NB 35,16

NB 30,60

NB 24

NB 20

N 33,3

NB 29,92

NB 25,84

N 42

NB 39

NB 33

NB 27,3

NB 22

kW

N 27,9

NB 26

NB 22,5

NB 17,65

NB 14,7

N 24,5

NB 22

NB 19

N 31

NB 28,6

NB 24,2

NB 20

NB 16,1

38÷40

43÷46

52÷56

66÷69

79÷82

43÷45

50÷53

62÷66

36÷38

40÷42

48÷51

59÷61

73÷76

3000

3000

2200

1800

1500

3000

3000

2200

3000

3000

2200

1800

1500

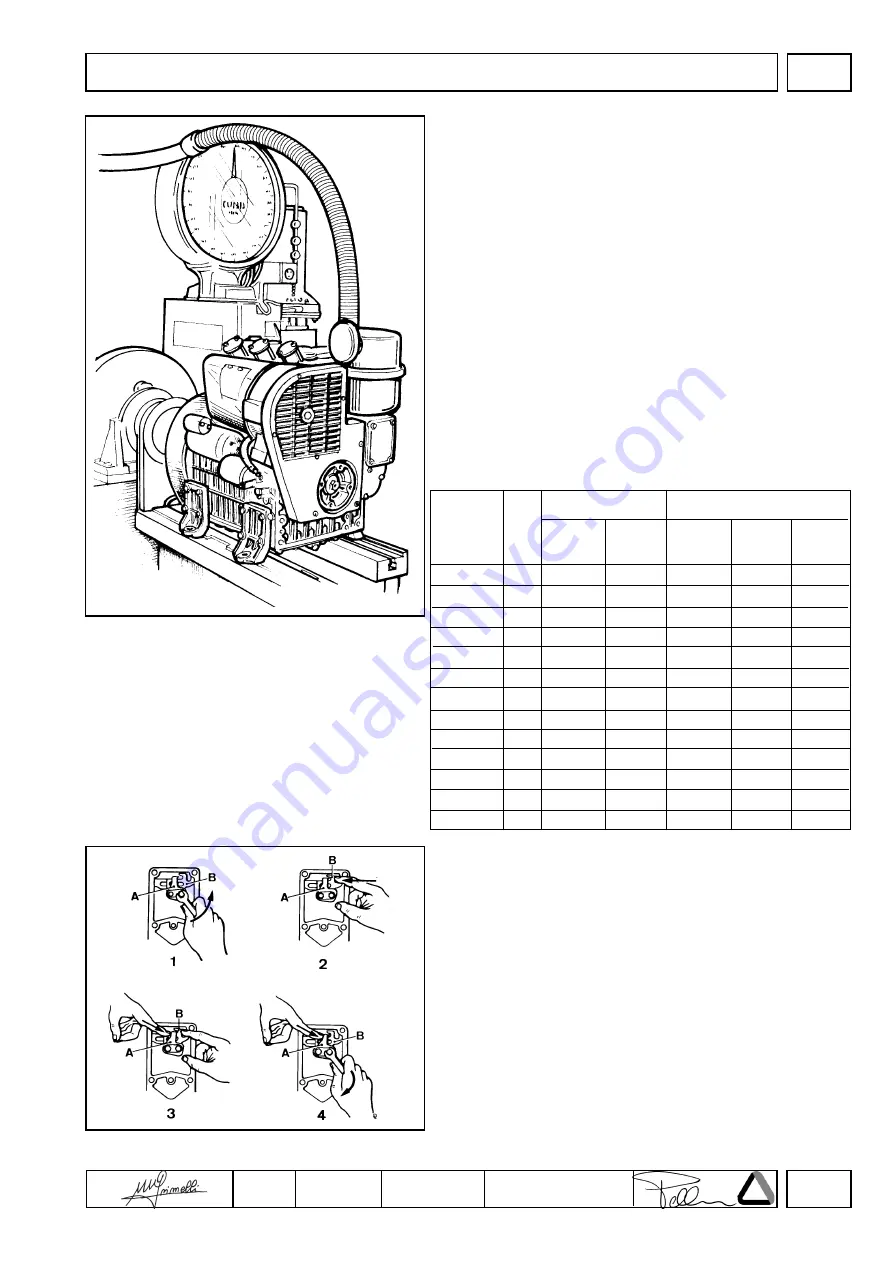

XII

Injection pump delivery setting with engine at the torque

dynamometer

1) Bring engine to idling speed

2) Unscrew delivery limiting device

C

(see page 59)

3) Bring engine to the power and r.p.m. required by the manufacturer

of the device,

4) Check that consumption falls within the table specifications (see

below). lf consumption is not as indicated change balance

conditions at the torque dynamometer by varying the load and

adjusting the governor.

Under stable engine conditions check consumption again.

5) Tighten limiting device

C

until the engine r.p.m. decreases. Lock

the iimiting device by means of lock nut.

In versions with manually-operated mechanical extra fuel feeding

D

perform this operation keeping drive rod

E

as shown in the figure.

6) Release brake completely and check at what speed the engine

becomes stable.

Speed governor should comply with the requirements of the class

indicated by the manufacturer of the device.

7) Stop the engine

8) Check valve clearance when the engine has cooled down.

Required settings (as most commonly applies)

Stop setting

Remove fuel feeding pump and cover.

1) Loosen both bolts fixing plate

A

.

2) Push injection pump

B

control rod to the right and keep it in this

position.

3) Push plate

A

to the right until it touches rod

B

and stop.

4) Release rod

B

and push plate

A

to the right so that rod

B

has a

stroke of 1 mm.

Tighten both bolts.

Note

: Under these conditions no damage can be caused to the

injection pump rack rod stops by sudden impacts due to the

available control solenoids.

SETTINGS

Time (sec.)

for 100 cmc

POWER

Specific fuel consumption

Engine

R.P.M.