- 16 -

Workshop Manual 12 LD _ cod. 1.5302.460 - 3° ed_ rev. 02

10

125

250

500

1000

2500

5000

(***)

(***)

(***)

(*)

(*)

(*)

(**)

(**)

(***)

(°)

(***)

(°)

3

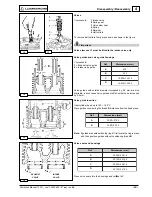

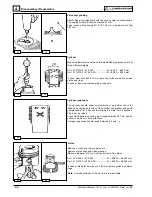

ENGINE OIL LEVEL

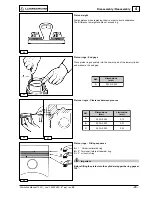

OIL BATH AIR CLEANER

DRY AIR CLEANER

FUEL PIPES

COOLING SYSTEM CLEANING

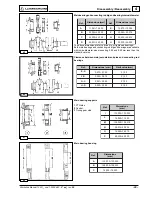

VALVE-ROCKER ARMS CLEARANCE

ADJUSTMENT

SETTING AND INJECTORS CLEANING

RUBBER INTAKE HOSE (DRY AIR

CLEANER - INTAKE MANIFOLD)

ENGINE OIL RADIATOR CLEANING

ALTERNATOR AND STARTING MOTOR

FUEL TANK CLEANING

ENGINE OIL

EXTERNAL OIL FILTER

FUEL FILTER

RUBBER INTAKE HOSE (DRY AIR

CLEANER - INTAKE MANIFOLD)

FUEL PIPES

DRY AIR CLEANER EXTERNAL

CARTRIDGE

DRY AIR INTERNAL EXTERNAL

CARTRIDGE

PARTIAL

TOTAL

Engine oil replacement.

Oil filter replacement.

EXTRAORDINARY MAINTENANCE

AFTER THE FIRST

50 WORKING HOURS

ORDINARY MAINTENANCE

OPERATION DESCRIPTION

FREQUENCY x HOURS

CHECK

REPLACEMENT

OVERHAUL

AFTER 6 CHECKS WITH CLEANING

(*)

-

In case of low use: every year.

(**)

-

In case of low use: every 2 years.

(***)

-

The period of time that must elapse before cleaning or replacing the filter element depends on the environment in which the engine operates.

The air filter must be cleaned and replaced more frequently In very dusty conditions.

(°)

-

Alternately when the clogging indicator, if present, indicates it’s necessary to replace the filter.

Failure to carry out the operations described in the table may lead to technical damage to the machine

and/or system

ROUTINE ENGINE MAINTENANCE

AFTER 3 CHECKS WITH CLEANING

MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING