- 20 -

Workshop Manual 12 LD _ cod. 1.5302.460 - 3° ed_ rev. 02

1

4

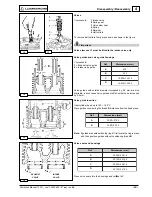

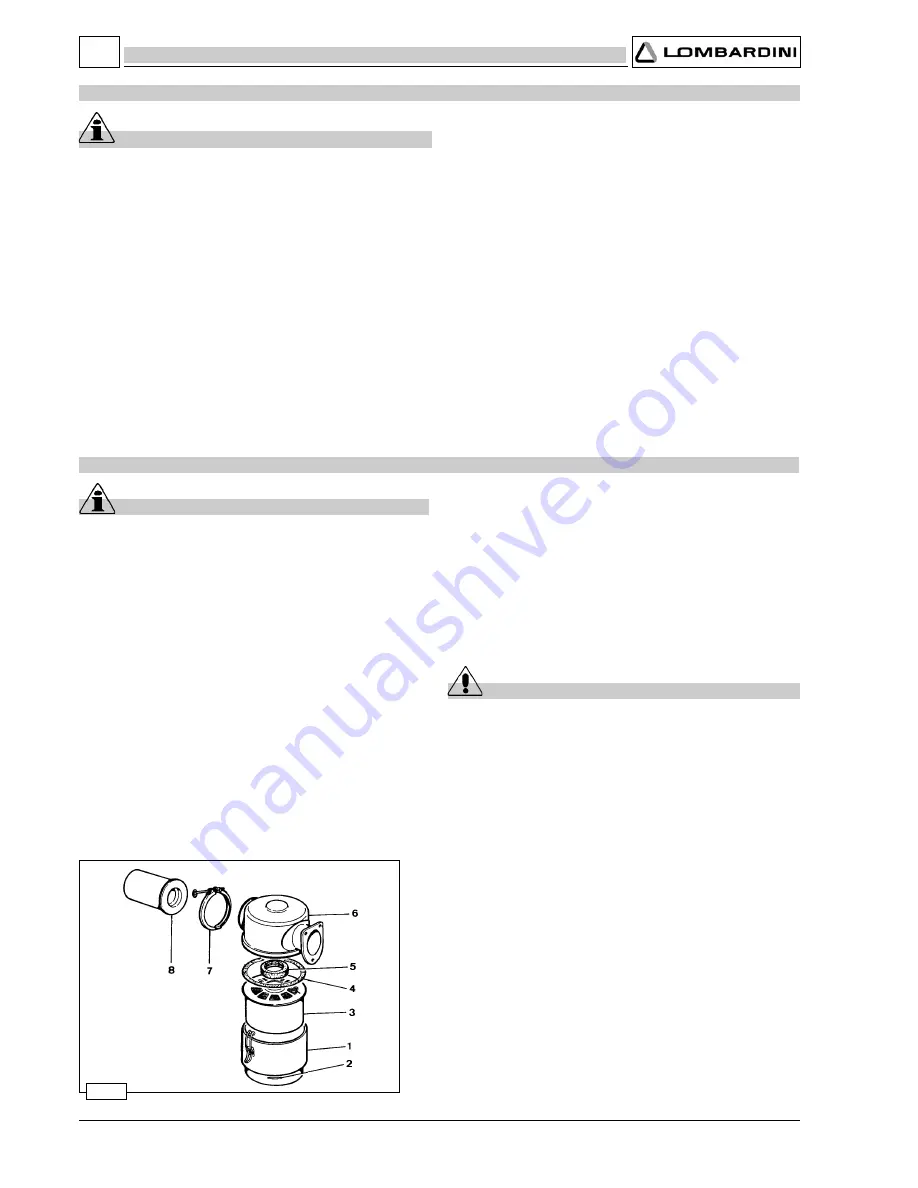

Oil-bath air cleaner

Check gaskets and replace if necessary.

Check that flange weld is free of porosity or defective spots.

Carefully clean bowl and filtering element with Diesel oil and blow

through with compressed air.

Top up with engine oil to the mark.

When refitting tighten nuts at 25 Nm.

See page 16 for periodic maintenance details.

Components:

1 Bowl

5 Internal seal ring

2 Oil level mark

6 Cover

3 Filtering element

7 Clamp

4 Seal ring

8 Prefilter

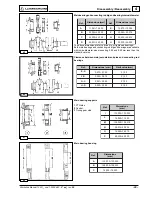

Important

To locate specific topics, the reader should refer to the

index.

–

Besides disassembly and reassembly operations this

chapter also includes checking and setting specifications,

dimensions, repair and operating instructions.

–

Always use original LOMBARDINI spare parts for proper

repair operations.

–

The operator must wash, clean and dry components and

assemblies before installing them.

–

The operator must make sure that the contact surfaces

are intact, lubricate the coupling parts and protect those

that are prone to oxidation.

–

Before any intervention, the operator should lay out all

equipment and tools in such a way as to enable him to

carry out operations correctly and safely.

–

For safety and convenience, you are advised to place the

engine on a special rotating stand for engine overhauls.

–

Before proceeding with operations, make sure that

appropriate safety conditions are in place, in order to

safeguard the operator and any persons involved.

–

In order to fix assemblies and/or components securely, the

operator must tighten the fastening parts in a criss-cross

or alternating pattern.

–

Assemblies and/or components with a specific tightening

torque must initially be fastened at a level lower than the

assigned value, and then subsequently tightened to the final

torque.

RECOMMENDATIONS FOR OVERHAULS AND TUNING

Important

To locate specific topics, the reader should refer to the

index.

–

Before any intervention, the operator should lay out all

equipment and tools in such a way as to enable him to

carry out operations correctly and safely.

–

The operator must comply with the specific measures

described in order to avoid errors that might cause damage

to the engine.

–

Before carrying out any operation, clean the assemblies

and/or components thoroughly and eliminate any deposits

or residual material.

–

Wash the components with special detergent and do not

use steam or hot water.

–

Do not use flammable products (petrol, diesel, etc.) to

degrease or wash components. Use special products.

–

Dry all washed surfaces and components thoroughly with

a jet of air or special cloths before reassembling them.

–

Apply a layer of lubricant over all surfaces to protect them

against oxidation.

–

Check all components for intactness, wear and tear, seizure,

cracks and/or faults to be sure that the engine is in good

working condition.

–

Some mechanical parts must be replaced en bloc, together

with their coupled parts (e.g. valve guide/valve etc.) as

specified in the spare parts catalogue.

Danger - Attention

During repair operations, when using compressed air,

wear eye protection.

RECOMMENDATIONS FOR DISASSEMBLING AND ASSEMBLING

DISASSEMBLY / REASSEMBLY