Operation Manual

60

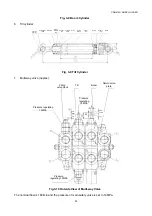

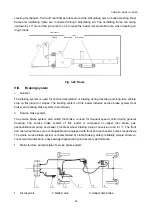

4.

Rear booster pump

5. Foot brake master valve

6. Front booster pump

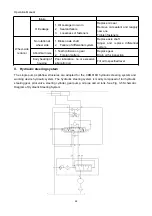

Fig. 3-21 Service brake system

The system structure is shown in Fig. 3-21. The compressed air from air compressor driven by engine

flows into air reservoir (1) through the relief valve (2) and the system pressure is 0.7~0.78MPa. One

port of the air reservoir is connected to the air inlet of air brake valve (5). The other port of the air

reservoir is equipped with an air take valve which is used to inflate tyres or remove the dust on diesel

engine air filter element.

Depress the pedal of brake master valve (5) and the compressed air from air reservoir flows into the

front booster pump (5) and rear booster pump (4) through the air brake valve. The pressure oil

pressurized by the rear booster pump pushes the piston of disc brake (3) to press the brake pad to

brake disc (pressure about 9.8MPa) to realize deceleration. Release the pedal and the compressed air

in front and rear booster pump flows into atmosphere to release the braking.

2.

Main components of service brake system:

The service brake system is composed of air compressor, relief valve, air reservoir, air brake master

valve, front and rear booster pumps, and disc brake.

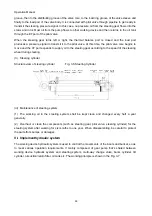

A. Air compressor

Air-cooled double-cylinder piston air compressor, one of diesel engine accessories, is fitted to the front

of fuel pump of diesel engine, driven by engine timing gear, provided with lubricating oil by the engine

and cooled by air. Air compressor air suction pipe is connected to inlet pipe of diesel engine. Engine oil

from diesel engine, limited by gauge hole, flows to oil sump of air compressor and the oil level is kept.

Excessive oil will return to diesel engine.

With no compressed air being used, after the air compressor works continuously for tens of minutes, if

the braking system pressure keeps stable, it means that the air compressor works normally; if the air

pressure drops significantly or fluctuates frequently, check the air discharge valve of air compressor

and carry out grinding if necessary to keep its tightness.

When the air compressor is working, there shall be no much oil seeping into compressed air. If the

engine oil accumulated in relief valve exceeds10-15cm

3

after 24 hours of working, find out the cause. If

the piston ring is worn seriously, replace it.

B. Relief valve

Purpose: It can automatically adjust the working pressure of air braking system and discharge the oil,

water and dust filtered by itself. It can also inflate tyre if equipped with a special joint.