32

Optional Equipment

© Travis Industries

100-01163

4041129

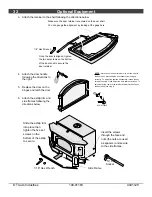

3. Attach the retainer to the shell following the directions below.

Make sure the door retainer is centered on the door shell.

You can gauge the alignment by looking at the gaps here.

Once the door is aligned, tighten

the two set screws on the bottom

of the door shell to secure the

door retainer.

1/8” Hex Wrench

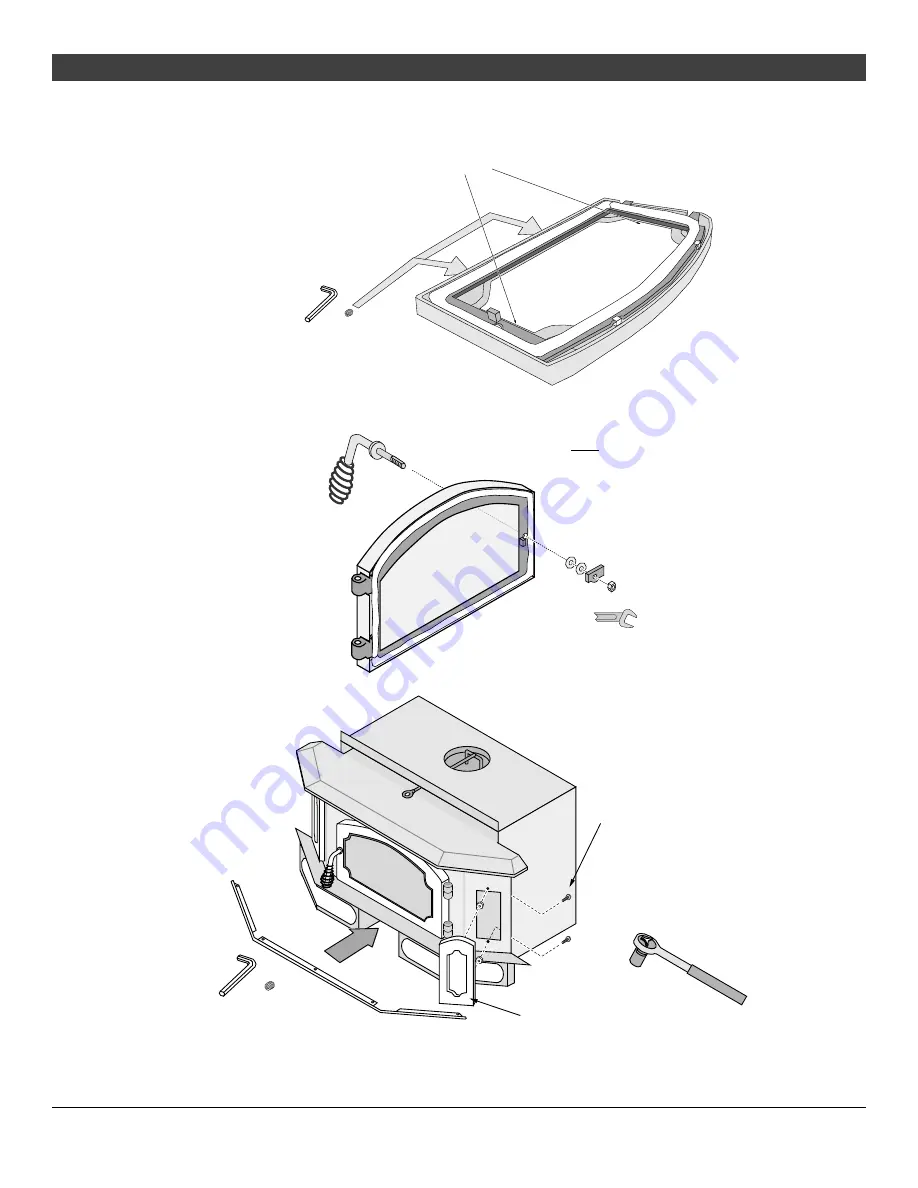

4. Attach the door handle

following the directions to

the right.

5. Replace the door on the

hinges and latch the door.

6. Attach the ashlip trim and

side frames following the

directions below.

9/16" Wrench

NOTE: in rare cases the door retainer may not line up with

the door shell, preventing the door handle from lining up

correctly. To adjust the position horizontally, loosen the set

screws (see step 3) and adjust the door retainer position. To

adjust vertically, remove the retainer and adjust the clips on

the door shell (see step 2).

Slide the ashlip trim

into place then

tighten the five set

screws on the

bottom of the ashlip

to secure.

1/16” Hex Wrench

Insert the screws

through the face and

nuts (the nuts are used

as spacers) and secure

to the side frames.

Side Frame

5/16”

Socket