- 15 -

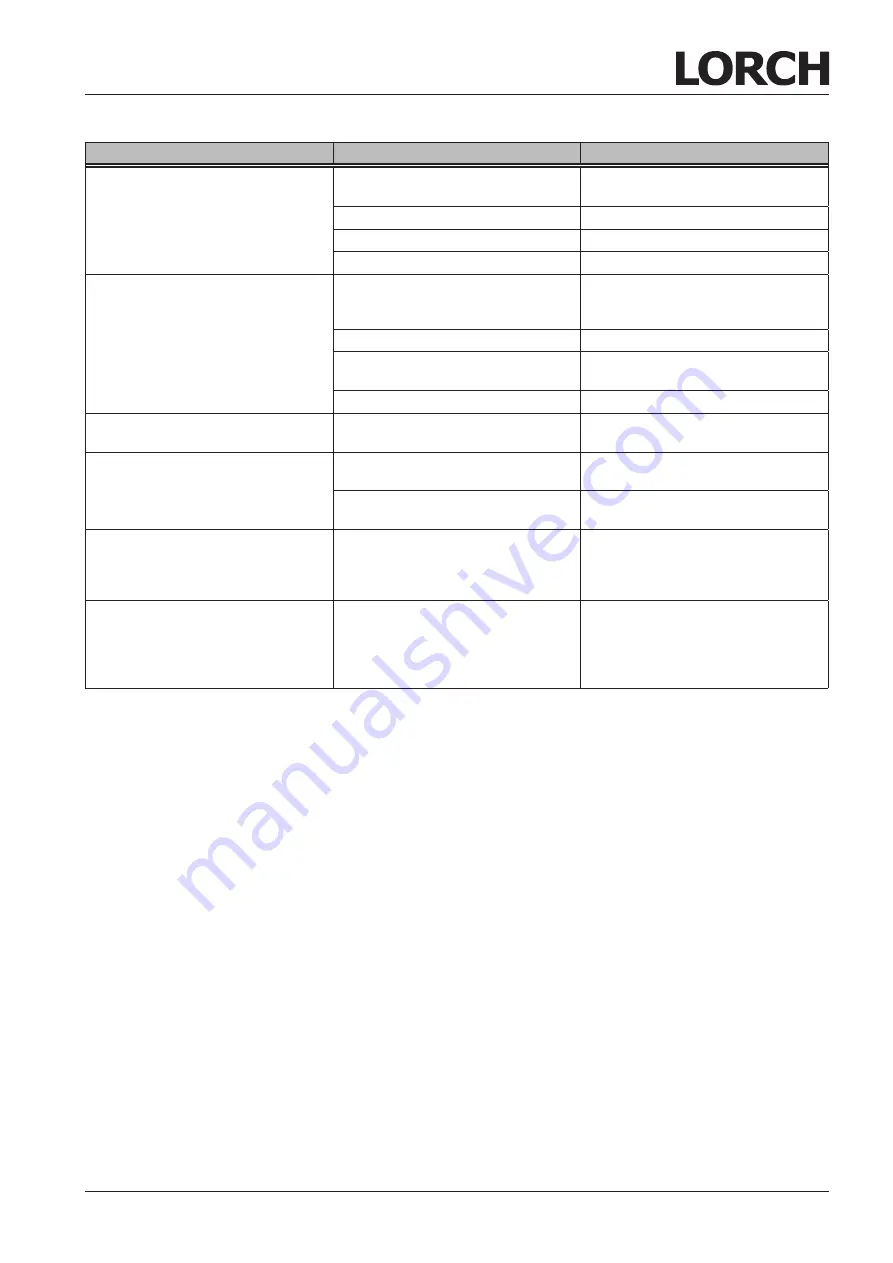

Troubleshooting

06.13

Fault

Possible cause

Rectification

Inert gas feed insufficient

Inert gas quantity set incorrectly at the

pressure reducer

Set the inert gas quantity as described

in the operating instructions

Pressure reducer dirty

Check the pressure reducing nozzle

Torch or gas hose blocked or leaking

Check and replace if necessary

Inert gas blown away by draughts

Eliminate the draughts

Welding power is reduced

Phase missing

Check the equipment using a different

power socket; check the supply cable

and the mains fuses

Insufficient ground contact at workpiece

Create a good clear ground connection

Ground cable not correctly inserted at

the equipment

Lock the ground connector at the equip-

ment by turning clockwise

Torch faulty

Repair or replacement

Ground cable connector becomes hot

The connector was not locked by turn-

ing clockwise

check

Wire feed unit has increased wire abra-

sion

The wire feed rollers do not match the

wire diameter

Fit the correct feed rollers

Incorrect contact pressure on wire feed

unit

Set as described in the operating in-

structions

Welding voltage and welding current

value blink on the V/A display when

welding and/or after welding (Hold dis-

play)

The set standard values were not

achieved and the installation overload

limit was activated.

Check and if necessary, correct the set

welding parameters.

Welding voltage, welding current: De-

viation between the set values and the

values measured during welding.

Depending on the actual welding pro-

cess, principally a deviation is possible

during short arc welding.

None:

This is a sign of the machine's "internal

control," stabilise the welding process

and increase the attainable quality of

welding.

Tab. 1: Troubleshooting