Specifications — Falk LTG

The values shown are typical and slight variations are

permissible.

AMBIENT TEMPERATURE RANGE — -20°F (-29°C) to 250°F

(121°C). Min. Pump = 20° F (-7° C).

MINIMUM BASE OIL VISCOSITY — 3300SSU (715cST) @

100°F (38°C).

THICKENER — Lithium & soap/polymer.

CENTRIFUGE SEPARATION CHARACTERISTICS — ASTM

#D4425 (Centrifuge Test) — K36 = 2/24 max., very high

resistance to centrifuging.

NLGI GRADE (ASTM D-217) —

1

/

2

CONSISTENCY (ASTM D-217) — 60 stroke worked

penetration value in the range of 315 to 360 measured at

77°F (25°C)

MINIMUM DROPPING POINT — 350°F (177°C) minimum

MINIMUM TIMKEN O.K. LOAD — 40 lbs.

ADDITIVES — Rust and oxidation inhibitors that do not

corrode steel or swell or deteriorate synthetic seals.

Packaging

14 oz. (0,4 kg ) CARTRIDGES — Individual or case lots of 10

or 30.

35 lb. (16 kg )PAIL, 120 lb. (54 kg ) KEG & 400 lb. (181 kg)

DRUMS.

General Purpose Grease

Annual Lubrication — The following specifications and

lubricants for general purpose grease apply to Falk Steelflex

couplings that are lubricated annually and operate within

ambient temperatures of 0°F to 150°F (-18°C to 66°C). For

temperatures beyond this range (see Table 1), consult

the Factory.

If a coupling leaks grease, is exposed to extreme

temperatures, excessive moisture or experiences frequent

reversals, more frequent lubrication may be required.

Specifications — General Purpose Coupling

Lubricants

The values shown are typical and slight variations are

permissible.

DROPPING POINT — 300°F (149°C) or higher.

CONSISTENCY — NLGI No. 2 with 60 stroke worked

penetration value in the range of 250 to 300.

SEPARATION AND RESISTANCE — Low oil separation rate

and high resistance to separation from centrifuging.

LIQUID CONSTITUENT — Possess good lubricating

properties equivalent to a high quality, well refined petroleum

oil.

INACTIVE — Must not corrode steel or cause swelling or

deterioration of synthetic seals.

CLEAN — Free from foreign inclusions.

General Purpose Greases Meeting Rexnord

Specifications

Lubricants listed below are typical products only and should

not be construed as exclusive recommendations.

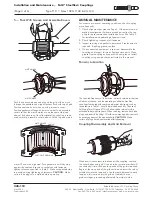

INSTALLATION OF TYPE T10 STEELFLEX

TAPERED GRID COUPLINGS

Installation

Only standard mechanics tools, wrenches, a straight edge and

feeler gauges are required to install Falk Steelflex couplings.

Coupling Sizes 1020T thru 1090T are generally furnished

for CLEARANCE FIT with setscrew over the keyway. Sizes

1100T and larger are furnished for an INTERFERENCE FIT

without a setscrew.

CLEARANCE FIT HUBS — Clean all parts using a non-

flammable solvent. Check hubs, shafts and keyways for burrs.

Do not heat clearance fit hubs. Install keys, mount hubs with

flange face flush with shaft ends or as otherwise specified and

tighten setscrews.

INTERFERENCE FIT HUBS — Furnished without setscrews.

Heat hubs to a maximum of 275°F (135°C) using an oven,

torch, induction heater or an oil bath. To prevent seal damage,

DO NOT heat hubs beyond a maximum temperature of 400°F

(205°C).

When an oxy-acetylene or blow torch is used, use an excess

acetylene mixture. Mark hubs near the center of their length in

several places on hub body with a temperature sensitive

crayon, 275°F (135°C) melt temperature. Direct flame towards

hub bore using constant motion to avoid overheating an area.

Rexnord Industries, LLC, Coupling Group

428-110

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone : 262-796-4060

May 2004

Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com

Supersedes 2-03

Installation and Maintenance

•

Falk™ Steelflex

®

Couplings

(Page 2 of 6)

Type T10

•

Sizes 1020–1140 & 20–140

TABLE 1 — General Purpose Greases

!

Ambient Temperature

Range

0°F to 150°F

(-18°C to 66°C)

-30°F to 100°F

(-34°C to 38°C)

Manufacturer

Lubricant

†

Lubricant

†

Amoco Oil Co.

Amolith Grease #2

Amolith Grease #2

BP Oil Co.

Energrease LS-EP2

Energrease LS-EP1

Chevron U.S.A. Inc.

Dura-Lith EP2

Dura-Lith EP1

Citgo Petroleum Corp. Premium Lithium Grease EP2 Premium Lithium Grease EP1

Conoco Inc.

EP Conolith Grease #2

EP Conolith Grease #2

Exxon Company, USA Unirex EP2

Unirex EP2

E.F. Houghton & Co. Cosmolube 2

Cosmolube 1

Imperial Oil Ltd.

Unirex EP2

Unirex EP2

Kendall Refining Co. Lithium Grease L421

Lithium Grease L421

Keystone Div. (Pennwalt) 81 EP-2

81 EP-1

Lyondell Petrochemical

(ARCO)

Litholine H EP 2 Grease

Litholine H EP 2 Grease

Mobil Oil Corp.

Mobilux EP111

Mobilith AW1

Petro-Canada Products Multipurpose EP2

Multipurpose EP1

Phillips 66 Co.

Philube Blue EP

Philube Blue EP

Shell Oil Co.

Alvania Grease 2

Alvania Grease 2

Shell Canada Ltd.

Alvania Grease 2

Alvania Grease 2

Sun Oil Co.

Ultra Prestige 2EP

Ultra Prestige 2EP

Texaco Lubricants

Starplex HD2

Multifak EP2

Unocal 76 (East & West) Unoba EP2

Unoba EP2

Valvoline Oil Co.

Multilube Lithium EP Grease . . .

!

Grease application or re-lubrication should be done at temperatures above 20°F

(-7°C). If grease must be applied below 20°F (-7°C), consult the Factory.

†

Lubricants listed may not be suitable for use in the food processing industry; check

with lube manufacturer for approved lubricants.

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......