Installation, Operation & Maintenance Manual

IM-995

9

Fan Installation – Factory Assembled Units

(refer to lifting/safety section)

All fan wheels are statically and dynamically balanced using state of the art equipment in the factory. Final trim balancing is

performed on factory assembled fans, unless the specified electrical characteristics of the motor are outside the limits of the

factory test equipment. If the motor and drives are supplied, the complete assembly is run tested and balanced. Infrequently,

fans are supplied with unusual electrical characteristics and cannot be tested with the motor. In this situation the fans are run

and balanced using a factory driver. Likewise, if motors and/or drives are not supplied, the fan is tested with the factory driver.

Final balancing, at the buyer’s expense, should be performed in the field after the motor and/or drives are installed. This service

is available from TCF, otherwise this should be entrusted to a qualified technician.

Follow proper handling instructions as given earlier.

1.

Move the fan to the final mounting position.

2. Remove skid, crates and packing materials carefully.

3. If vibration isolation is to be used, place isolation base on

mounting bolts. Line up holes in fan base with bolts. See

Item 10 in the "Optional Accessories" section for preparing

inertia bases for use.

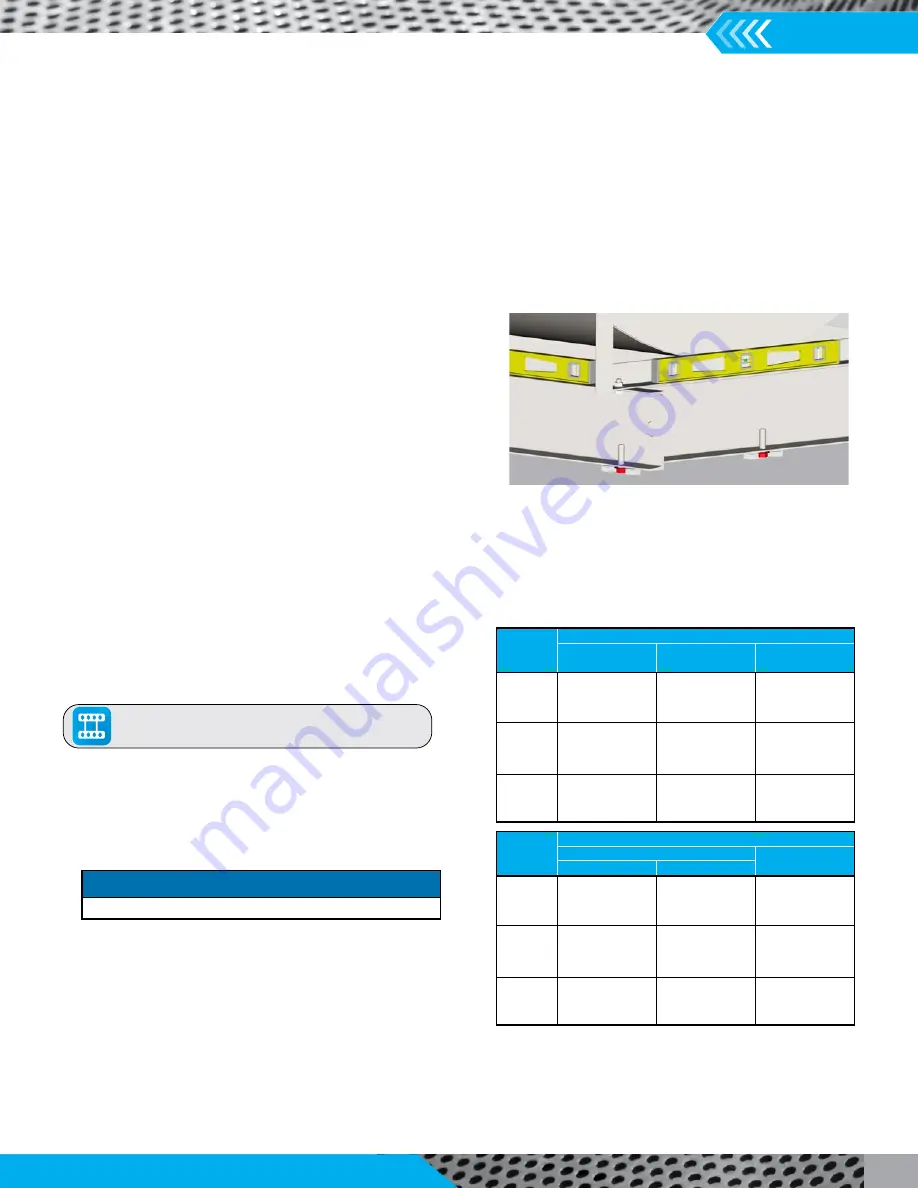

4. Place the fan on mounting structure. Carefully level the

unit (checking the level on the shaft) on the foundation

and shim as necessary using stainless steel shims on both

sides of each anchor bolt. Back off leveling nuts if used.

Be careful not to force the fan to the mounting structure/

foundation. This may cause the bearings to become

misaligned or pinched causing vibration and premature

failure.

5. Check the alignment of the bearings. Shim or reposition

the bearings if necessary.

6. Check alignment of sheaves on belt driven fans.

7. Check tension of belts to see if it is sufficient. Sheaves

on belt driven fans are often provided with taperlock

bushings. When tightening bushing bolts, proceed in a

progressive manner to avoid cocking the tapered surfaces

between the bushing and the sheave. Torque per tables

on the right.

8. Check alignment of factory mounted couplings, as

they are subject to misalignment during shipment and

installation. Realign to within 0.002" offset and parallel.

Allow for thermal growth of the motor by setting the

motor 0.001" low for each inch of shaft up to 0.005".

9. Check the tightness of the wheel on the shaft. Check

the tightness of foundation bolts, motor bolts, sheaves

and bearings. Make sure there is no rubbing or binding

and that the wheel-inlet cone clearances and overlap are

correct.

10. Check that bearings are fully lubricated and check the

oil level in the static oil lube systems. For spherical roller

bearings with split pillowblock housings, the bottom half

of the housings should be 1/3 full of grease. For oil lube

bearings, the oil level should reach the midpoint of the

bottom roller or ball.

11. Install any accessories shipped loose from the factory.

The above torque values are for nonlubricated fasteners and Browning

Bushings. For bearing setscrews, use manufacturer’s recommendations.

If other bushings are used, utilize bushing manufacturer's specifications.

Tolerance: +/-

5%

For wheel setscrews use Grade 2 values.

SIZE

FASTENER - TIGHTENING TORQUE (Ft. Lbs.)

GRADE 2

GRADE 5

GRADE 8

#10

—

—

—

1

Τ

4

-20

5.5

8

12

5

Τ

16

-18

11

17

25

3

Τ

8

-16

22

30

45

7

Τ

16

-14

30

50

70

1

Τ

2

-13

55

75

110

9

Τ

16

-12

—

—

—

5

Τ

8

-11

100

150

200

3

Τ

4

-10

150

270

380

7

Τ

8

-9

165

430

600

1-8

250

645

900

1

1

Τ

4

-7

500

1120

1500

SIZE

TAPER BUSHINGS - TIGHTENING TORQUE (Ft. Lbs.)

SPLIT

QD

FOR DRIVE

IN IRON

IN ALUM. HUB

#10

—

—

6

1

Τ

4

-20

7.9

7.5

9

5

Τ

16

-18

16

13

15

3

Τ

8

-16

29

24

30

7

Τ

16

-14

—

—

—

1

Τ

2

-13

70

—

60

9

Τ

16

-12

—

—

75

5

Τ

8

-11

140

112

135

3

Τ

4

-10

—

—

—

7

Τ

8

-9

—

—

—

1-8

—

—

—

1

1

Τ

4

-7

—

—

—

Tightening Torque

Carefully level the fan on the foundation

Click To View Our

Sheave Installation video

NOTICE

Most couplings need lubrication.

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......