8

Model 121 Regulators Brochure

Maximum emergency Pressures

NOTe:

Before using any of the following data, make sure this

entire section is clearly understood.

The maximum pressure the regulator inlet may be subjected

to under abnormal conditions without causing damage to the

regulator is:

¾" through 2½" Pipe Sizes ................................ 70 psi

3" Pipe Size ....................................................... 50 psi

4" Pipe Size ....................................................... 25 psi

The maximum pressure the regulator outlet may be subjected to

without causing damage to the internal parts of the regulator is:

121-8 ................................................. set-point + 5 psi

121-8HP .......................................... set-point + 10 psi

121-12 ............................................... set-point + 5 psi

121-16 ............................................... set-point + 2 psi

6HWSRLQWLVGH¿QHGDVWKHRXWOHWSUHVVXUHDUHJXODWRULVDGMXVWHG

to deliver. If any of the above pressure limits are exceeded, the

regulator must be taken out of service and inspected. Damaged

parts must be repaired or replaced.

The maximum pressure that can be safely contained by the

diaphragm case is:

121-8 ................................................................. 25 psi

121-8HP ............................................................ 25 psi

121-12 ............................................................... 20 psi

121-16 ............................................................... 10 psi

Safely contained means no leakage as well as no bursting.

Over-pressurization Protection

Protect the downstream piping system and the regulator’s low

pressure chambers against over-pressurization due to the

possible regulator malfunction or failure to achieve complete

lockup. The allowable outlet pressure is the lowest of the

maximum pressures permitted by federal codes, state codes,

Sensus bulletin RDS-1498, or other applicable standards. The

method of protection can be a relief valve, monitor regulator,

shutoff device, or similar mechanism.

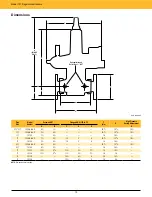

Full Open Capacity

Capacity of the Model 121 in the full open position can be

calculated using the following formulas and K factors:

1. Q = K

¥

P

0

(P

1

– P

0

................ (for P

1

/P

0

ʘOHVVWKDQ

2. Q =

K P

1

2

............................... (for P

1

/P

0

ʘJUHDWHUWKDQ

4 )XOORSHQFDSDFLW\LQ6&)+RIVSHFL¿FJUDYLW\

natural gas.

P

1

=

absolute

LQOHWSUHVVXUHSVLD

P

0

=

absolute

RXWOHWSUHVVXUHSVLD

3LSH6L]HRXWOHW

........................................ K=1400

1½" Pipe Size ................................................. K=2750

2" Pipe Size .................................................... K=4750

2½" Pipe Size ................................................. K=5250

ó3LSH6L]HRXWOHW

..................................... K=1750

3" Pipe Size .................................................. K=11000

4" Pipe Size .................................................. K=18000

Remember, at the above full open capacities the droop is

VLJQL¿FDQWO\JUHDWHUWKDQVSHFL¿HGLQWKHFDSDFLW\WDEOHVRQ

pages 4, 5, 6 and 7.

When checking 121 regulator capacity for use in providing

adequate relief capacity, use the above calculated full open

capacity. Do not use 121 capacity values from the tables on

pages 4, 5, 6 and 7.

Pipe Sizes

6FUHZHG137

)ODQJHG$16,

125 lb. FF.

¾" x 1"

1½" x 1½"

2" x 2"

¾" x 1¼"

1½" x 2"

3" x 3"

1" x 1"

2" x 2"

4" x 4"

1" x 1¼"

2½" x 2½"

1¼" x 1¼"

3" x 3"

Other gases

Model 121 Regulators are most widely used with natural gas.

However, they perform equally well with LP gas, nitrogen, dry

CO

2

and air.

For other gas capacities, multiply the table values on page 4, 5, 6

and 7 by the applicable correction factors:

7\SHRI*DV

&RUUHFWLRQ)DFWRU

$LU6SHFL¿F*UDYLW\

0.77

3URSDQH6SHFL¿F*UDYLW\

0.63

%783URSDQH$LU0L[6SHFL¿F*UDYLW\

0.71

1LWURJHQ6SHFL¿F*UDYLW\

0.79

'U\&DUERQ'LR[LGH6SHFL¿F*UDYLW\

0.63

For other non-corrosive gases use the following formula:

0.60

CORRECTION FACTOR =

¥

6SHFL¿FJUDYLW\RIWKHJDV

For use with gases not listed above, please contact your Sensus

representative or Industrial Distributor for recommendations.

CAUTION

Turn gas on slowly. If an outlet stop valve is used, it should

EHRSHQHG¿UVW'RQRWRYHUORDGWKHGLDSKUDJPZLWKDVXGGHQ

surge of inlet pressure. Monitor the outlet pressure during

start-up to prevent an outlet pressure overload. ReFeR TO

RM-1328 FOR MORe DeTAIleD START-uP PROCeDuReS.

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......