9

Model 121 Regulators Brochure

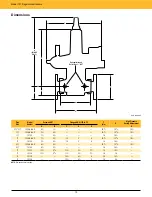

Materials of Construction

Body and Adapter ...................................................Cast Iron

Diaphragm Case

DQG'LDSKUDJP««««'LH&DVW$OXPLQXP$OOR\

Diaphragm Case

'LDSKUDJP

.............Permanent Mold Aluminum Alloy

Main and Seal Diaphragms ....................... Buna-N on Nylon

Piston for Seal Diaphragm

ôWKUXò0RGHO

.........Powdered Iron-Zinc Plated

Piston for Seal Diaphragm

DQG0RGHO

................................Aluminum Alloy

Stem, Stud, Pans and Plates for

8", 12" and 16" Diaphragms .......................Stainless Steel

Stem bushing ................................................Stainless Steel

2UL¿FH

¾

WKUXó0RGHO

................................... Brass

2UL¿FHòWKUX0RGHO

..............................Cast Iron

5HWDLQLQJ5LQJòWKUX0RGHO

............ Plated Steel

Valve .................Plated Steel with Molded Buna-N Soft Seat

Valve Holder ..................................................Stainless Steel

Retaining Ring and Wave Washer.................Stainless Steel

O-Rings and Tetraseals ............................................ Buna-N

Adjustment Spring Ferrule .......................... Zinc Die Casting

Bottom Spring Button .........................Powdered Iron-Plated

$GMXVWPHQW6FUHZ'LDSKUDJPDQG

+3$GMXVWPHQW6SULQJ)HUUXOH

..................... Plated Steel

$GMXVWPHQW)HUUXOH6FUHZ'LDSKUDJP

and H.P. Adjustment Spring Ferrule ....................Cast Iron

6HDO&DSDQG'LDSKUDJP

.............. Zinc Die Casting

6HDO&DS'LDSKUDJP

............ Die Cast Aluminum Alloy

Body Taps

Inlet and outlet taps are available on either side of the body. Tap

size is ¼" NPT. Refer to “dimensions” on page 13. Desired taps

PXVWEHVSHFL¿HGZKHQRUGHULQJ

Metrication

Use the following for Metric Conversions:

std. meters

3

/hr. x 35.31 = std. ft.

3

/hr. (SCFH)

std. ft.

3

/hr. (SCFH) x 0.0283 = std. meters

3

/hr.

kilograms/centimeter²(kg/cm²) x 14.22 = psig

psig x 0.0703 = kilograms/centimeters²(kg/cm²)

kilopascals (kPa) x 0.145 = psig

psig x 6.90 = kilopascals (kPa)

bars x 14.50 = psig

psig x 0.69 = bars

millimeters water (mm H

2

O) x .0394 = in. w.c.

in. w.c. x 25.4 = millimeters water (mm H

2

O)

millimeters mercury (mm Hg) x 0.535 = in w.c.

in. w.c. x 1.868 = millimeters mercury (mm Hg)

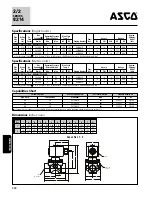

How to order

Specify:

1.

Model Number.

2.

3LSHVL]HRQDQGVSHFLI\ZKHWKHUVFUHZHGRUÀDQJHG

3.

Inlet pressure.

4.

Outlet Pressure.

5.

Capacity required — SCFH.

6.

.LQGRIJDVQDWXUDOJDVSURSDQHDLUHWF

Buried Service

These regulators are designed for above ground or vault

installations and are not recommended for direct earth burial.

Temperature limits

0RGHOUHJXODWRUVFDQEHXVHGIRUWHPSHUDWXUHVIURP)

WR)

CAUTION

It is the user’s responsibility to ensure all regulator vents and/

or vent lines exhaust to a non-hazardous location away from

ANY POTeNTIAl sources of ignition. Refer to Sensus Bulletin

RM-1328 for more detailed information.

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......