PARTS LIST

ITEM

DESCRIPTION

MATERIAL

1

Body

Cast Iron (ASTM A 126, Class B)

2

Screen

Stainless Steel (304)

3

Bushing

Malleable Iron

4

Gasket*

Composition

5

Cap Screw*

Steel

6

Cover*

Cast Iron (ASTM A 126, Class B)

Style B

Y-Strainer, 250 lb. Threaded

Cast Iron (ASTM A 126, Class B)

Certified dimensional drawings are available upon request.

†

This table reflects only the nearest metric equivalents.

TECHNICAL DATA

DIMENSIONS AND WEIGHTS

KECKLEY COMPANY

•

3400 Cleveland Street

•

Skokie, Illinois 60076

1-800-KECKLEY

Y3

SIZE

DIMENSIONS

WEIGHTS

A

B

E

in

mm

in

mm

in

mm

in

mm

lbs

kgs

1/4

8

3

76

2-5/8

67

3/8

10

2

0.9

3/8

10

3

76

2-5/8

67

3/8

10

2

0.9

1/2

15

3

76

2-5/8

67

3/8

10

2

0.9

3/4

20

4

102

3-5/8

92

1/2

15

3

1.4

1

25

4-7/8

124

4-1/2

114

3/4

20

4.5

2.0

1-1/4

32

5-1/8

130

4-3/4

121

3/4

20

6

2.7

1-1/2

40

5-3/4

146

4-7/8

124

1

25

8

3.6

2

50

7-1/4

184

5-3/4

146

1-1/4

32

15.5

7.0

2-1/2

65

8-7/8

225

7-1/2

191

1-1/4

32

25

11.3

3

80

10

254

8

203

1-1/2

40

36

16.3

4

100

15-1/4

387

12-1/2

318

2

50

95

43.1

Size

(in

2

)

Size

(in

2

)

Size

(in

2

)

1/2”

5.50

1-1/4”

18.69

2-1/2”

54.13

3/4”

8.59

1-1/2”

23.37

3”

73.51

1”

15.22

2”

36.23

4”

154.98

TOTAL SCREEN AREA

0

100

200

300

400

500

Temperature [

°F

]

0

100

200

300

400

500

Maximum Pressure

and Temperature Limits

250 PSI at 406F

400 PSI at 150F

690

1379

2069

2759

3449

Temperature [ ]

°C

38

93

149

204

Pressure [

PSI

]

260

Pressure [

KPa

]

250# Class

PRESSURE vs. TEMPERATURE CHART

250# Threaded Cast Iron (ASTM A 126, Class B)

*In Accordance with ASME B16.4

Optional: Blow-off Plug, Malleable Iron *2

½

”, 3” & 4” only.

07/12

STANDARD SCREENS SUPPLIED

SIZE

SCREEN

GAGE

SCREEN PERFORATION

FOR STEAM OPEN

AREA

FOR LIQUID OPEN

AREA

in

mm

in

mm

in

mm

1/4 to 2

8 to 50

20 MESH STAINLESS STEEL

49%

2-1/2 to 4 65 to 100

28

3/64

1.2

33%

1/16

1.6

30%

Standard screens supplied are for

liquid service

, unless otherwise specified.

Options: Other meshes, perforations, and screen materials are available.

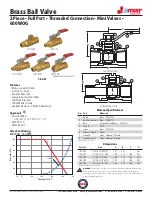

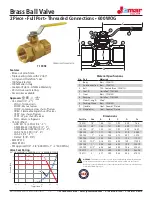

Size

Cv

Size

Cv

Size

Cv

1/2”

9.5

1-1/4”

44.9

2-1/2”

129.7

3/4”

18.7

1-1/2”

61

3”

161.3

1”

30

2”

98

4”

256.2

FLOW COEFFICIENTS

*See DETERMINING RATIOS on page

S5

of the

Strainer Information Section for calculating NET FREE

AREA of the screen to inside pipe area.

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......