Technical

Instructions

SKPx5.xxxUx

Electro

Ͳ

hydraulic

actuators

Document

Number

CC1N7643us

December

10,

2018

Page

14

Siemens

AG

Building

Technologies

Installation

WARNING:

•

Personal

injury

or

loss

of

life

may

occur

if

procedures

are

not

followed

as

specified.

•

All

installations

must

be

performed

by

qualified

personnel

only.

•

Do

not

pull

the

actuator

shaft.

•

The

AGA66

gasket

must

be

installed

between

the

actuator

and

the

gas

valve

body

to

provide

NEMA

3,

3R,

and

4

protection

rating

for

VGG10.xxxU

and

VGDxx.xxxU

valves

if

a

liquid

Ͳ

tight

conduit

connection

is

used.

)

NOTE:

Wiring

must

meet

all

relevant

electrical

codes.

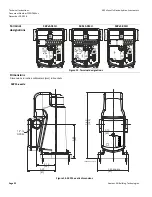

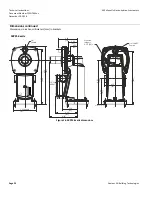

•

The

SKPx5.xxxUx

actuator

is

directly

coupled

to

the

VGxxx.xxxU

series

valve

body

by

four

premounted

4

mm

Allen

(R)

key

screws.

•

The

square

mounting

flange

can

be

rotated

in

steps

of

90°

to

provide

four

different

mounting

positions.

The

SKPx5.xxxUx

actuator

can

be

mounted

in

any

position

with

the

diaphragms

vertical,

except

upside

down.

•

The

actuator

can

be

mounted

or

replaced

while

the

valve

body

is

under

pressure.

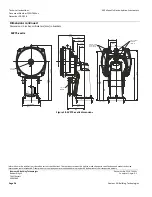

•

The

SKPx5.xxxUx

actuator

has

two

knock

Ͳ

outs

for

the

installation

of

1/2”

Ͳ

14

NPSM

conduit

connections.

•

When

conduit

routing

is

connected,

flexible

conduit

must

be

used.

•

Liquid

tight

flexible

conduit

must

be

used

in

combination

with

AGA66

to

provide

NEMA

3,

3R,

and

4

protection.

•

The

terminal

marked

GND,

located

above

the

wiring

terminals,

must

be

connected

to

the

electrical

ground.

The

pressure

pick

Ͳ

up

connections

must

be

flush

with

the

inner

wall

of

the

pipe

or

housing

in

order

to

sense

turbulence

Ͳ

free

pressures.

The

pressure

pick

Ͳ

up

connections

should

be

located

at

least

5

pipe

diameters

downstream

of

the

valve,

damper,

elbow,

coupling,

orifice,

or

other

flow

disturbing

fitting.

Using

the

taps

on

the

valve

body

for

gas

connection

to

the

regulator

may

show

turbulence.

SKP25.xxxUx,

SKP55.xxxUx

and

SKP75.xxxUx

•

If

minimum

gas

pressure

detection

is

required,

the

pressure

switch

must

be

mounted

upstream

of

the

regulating

gas

valve

or

if

mounted

downstream

electrically

by

Ͳ

passed

to

ensure

sufficient

gas

pressure

before

starting

the

burner.

If

mounted

downstream.

•

The

gas

pressure

sensing

line

must

be

at

least

1/4

Ͳ

inch

inside

diameter.

•

The

pressure

connection

pipe

should

be

as

short

as

possible

to

allow

the

regulator

to

react

to

sudden

changes.

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......