Rexnord

®

Planetgear™ 7000 Series Speed Reducer

s

Owners Manual

Sizes Neptune, Neptune Plus, Orion Plus, Saturn Plus & Titan Plus (Page 5 of 32)

Rexnord

158-170

3001 W. Canal St., Milwaukee, WI 53208-4200

January 2015

Telephone: 414-937-4359 Fax: 414-937-4359 www.rexnord.com

Supersedes 11-12

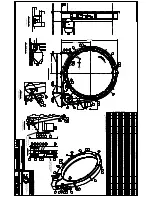

2.3.1b. MOTORS (C-FACE & IEC MOTOR

FLANGE UNITS) – Neptune, Neptune Plus,

& Orion Plus Quad/Quint Only

1. Mount the reducer C-face coupling or IEC motor flange

coupling onto the motor shaft with the appropriate size

key. The motor shaft to coupling fit should be snug

and may require light tapping (

NOTE

: Warming up

the coupling and applying an Anti-seize compound to

the motor shaft is helpful).

NOTE

: A loose fit coupling

should be avoided and a heavy fit could damage motor

bearings if the coupling is pressed onto the motor shaft

with extreme force.

CAUTION

: Never turn down the motor shaft diameter

to allow for easy coupling installation, as this will cause

coupling movement and wear during operation.

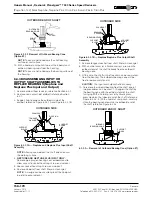

2.a. C-FACE: Locate the C-Face coupling 0.688 to 0.750” from

the motor face (Hint: Standard keystock is helpful for this

purpose). Refer to the illustration in Figure 2.3.1 b.

0.500”

0.625”

DOUBLE

LIPPED

SEAL

(NEPTUNE

QUADRUPLE/QUINTUPLE)

HOLD DIMENSION WHEN

MOUNTING INPUT

COUPLING TO

MOTOR SHAFT

SETSCREWS

C-FACE COUPLING

REDUCER

INPUT GEAR

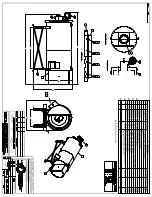

Figure 2.3.1b C-Face Cross Section

INTEGRAL

HUB SEAL

INTERGAL

COUPLING

INPUT

GEAR

THRUST

WASHER (2)

THRUST

BEARING

SEEP HOLE MUST BE MOUNTED

IN THE 6 O’CLOCK POSITION

13 mm

15 mm

HOLD DIMENSIONS WHEN

MOUNTING INPUT COUPLING

TO MOTOR SHAFT

MOTOR

SHAFT

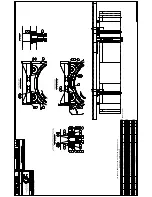

Figure 2.3.1c IEC Cross Section

3. Tighten the coupling set screws; one located over

the key and the other located at 90° (degrees). After

tightening the set screws, the gap between the motor

face and the coupling should be measured again to

insure that the tolerance has been maintained. If the

tolerance is not within the specification, loosen the set

screws and repeat steps 2 and 3.

4. Mount the motor with coupling to the reducer. Align the

internal spline end of the coupling with the external

spline end of the reducer input gear.

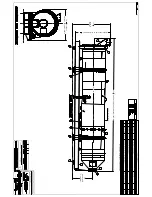

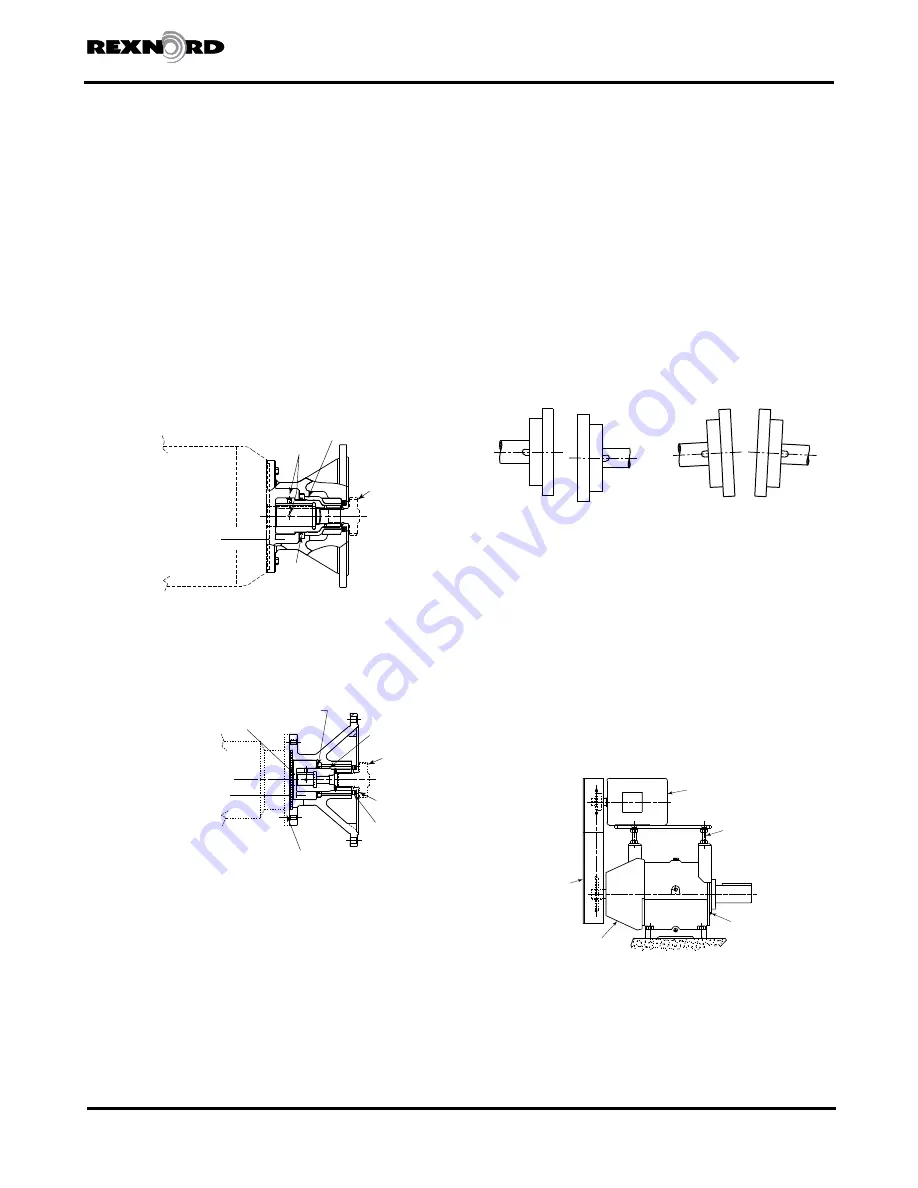

PARALLEL MISALIGNMENT

ANGULAR MISALIGNMENT

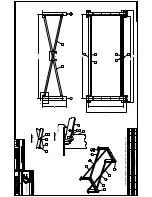

Figure 2.3.2 Parallel and Angular Misalignment

CAUTION

: Be careful not to roll the seal when installing

or removing the coupling and motor. This could result in

oil leakage during operation.

5. Align the mounting holes of the motor with the mounting

holes of the reducer, and fasten, reference Table 17

(Page 28) for recommended bolt torques.

2.3.2 COUPLINGS

Mount the reducer coupling hub on the input shaft and the

motor coupling hub on the motor shaft as instructed in the

manual shipped with the coupling. If the coupling is not a

Rexnord® Omega®, refer to the manufacturers literature

for installation instructions. If Rexnord does not mount

the motor, the couplings are mounted for shipment only.

Coupling bolts and coupling instructions are packed inside

the coupling elements. Note: Prior to the installation of the

element, check both coupling hubs for the required parallel

and angular alignment; Reference Figure 2.3.2.

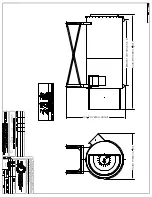

MOTOR

THREADED

SUPPORT

BOLTS

REDUCER

REDUCER

FAN/SHROUD

GUARD

Figure 2.3.3 Planetgear 7000 Top Motor Mount

2.b. IEC MOTOR FLANGE COUPLING: Locate the coupling

13.0 to 14.0mm from the motor face. Refer to the

illustration in Figure 2.3.1 c.

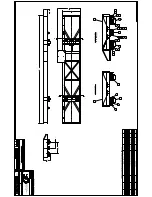

2.3.3 SPROCKETS OR SHEAVES

Prior to installing sprockets or sheaves, review the

manufacturers requirements for chain or belt tension and

required alignment. When mounting the sprocket or sheave to

the shaft, locate it as close as possible to the reducer. This will

minimize the overhung load and prolong bearing life.

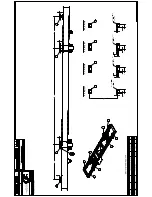

When using a Planetgear 7000 top motor mount accessory,

the belt tension can be changed by varying the height of

the motor mount plate. This can be done by adjusting the

four threaded support bolts. Reference Figure 2.3.3.

NOTE

: Mount sheaves and belts as close to the reducer as

possible to avoid undue overhung loading on the bearings.

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......