Owners Manual

s

Rexnord

®

Planetgear™ 7000 Series Speed Reducers

(Page 6 of 32) Sizes Neptune, Neptune Plus, Orion Plus, Saturn Plus & Titan Plus

158-170

Rexnord

January 2015

3001 W. Canal St., Milwaukee, WI 53208-4200 USA

Supersedes 11-12

Telephone:414-342-3131 Fax: 414-937-4359 www.rexnord.com

Section

III

— Lubrication

INTRODUCTION

Carefully follow instructions on the drive nameplate,

warning tags and installation manuals furnished with the

drive. Failure to follow instructions will void warranty.

Lubricants listed in this manual are typical products

ONLY and should not be construed as exclusive

recommendations. Industrial type extreme pressure (EP)

or industrial type micropitting resistant gear lubricants are

the required gear lubricants. They can be formulated using

petroleum or synthetic base stocks.

Summary of allowable lubricant types by unit size can be

found in Table 1

The section on food grade lubricants provides guidance

in selecting lubricants for applications needing this class

of lubricants. Food grade lubricants are formulated using

petroleum or different types of synthetic base stocks.

WARNING

: Failure to use extreme pressure or micropitting

resistant type lubricants in Planetgear Neptune, Neptune

Plus, Orion Plus, Saturn Plus, & Titan Plus size units will

void warranty.

TABLE 2 — Summary of Lubricant Type and

Greases

Petroleum-Based

Extreme Pressure (EP)

See Table 6A

Micropitting Resistant

See Table 6B

Synthetic Lubricant, Polyalphaolefin Type (PAO)

Extreme Pressure (EP)

See Table 7A

Micropitting Resistant

See Table 7B

Conventional Grease

See Table 8

Food Grade Lubricant & Grease

See Page 10

LUBRICANT SELECTION PROCESS

1. Refer to Tables 4 and 5 for proper lubricant viscosity

grade based on ambient temperature range.

2. Refer to Table 2 for summary of lubricant type.

3. Using proper lubricant table and viscosity grade, select

desired lubricant manufacturer and name.

4. Refer to Table 3 for approximate oil capacity to

purchase

VISCOSITY (IMPORTANT)

The proper viscosity grade for petroleum-based lubricants

is found in Table 4. For synthetic lubricant viscosity grades,

refer to Table 5 and the “Synthetic Lubricants” paragraphs.

Viscosity grade is determined by ambient air temperature

in the immediate vicinity of the gear drive. Lubricant

selections must have a pour point at least 10°F

(5.5°C) below the expected minimum ambient starting

temperature.

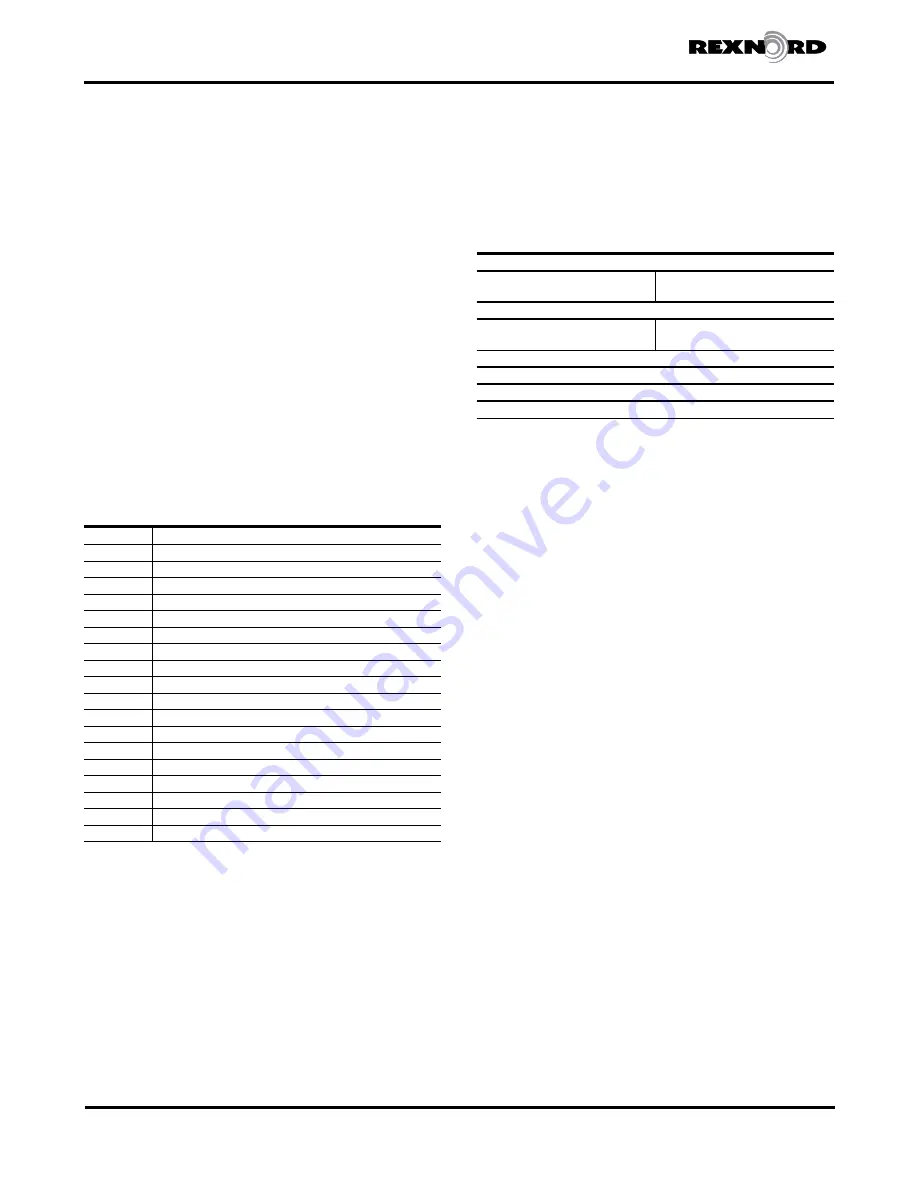

TABLE 1 — Summary Of Allowable

Lubricant Types For Planetgear

Footmounted Units

À

UNIT SIZE

Allowable Lubricant Types

Mercury

Rust & Oxidation Inhibited, Extreme Pressure, Micropitting Resistant

Mars

Rust & Oxidation Inhibited, Extreme Pressure, Micropitting Resistant

Venus

Extreme Pressure, Micropitting Resistant

Atlas

Extreme Pressure, Micropitting Resistant

Luna

Extreme Pressure, Micropitting Resistant

Earth

Extreme Pressure, Micropitting Resistant

Polaris

Extreme Pressure, Micropitting Resistant

Delta

Extreme Pressure, Micropitting Resistant

Neptune

Extreme Pressure, Micropitting Resistant

Neptune Plus

Extreme Pressure, Micropitting Resistant

Orion

Rust & Oxidation Inhibited, Extreme Pressure, Micropitting Resistant

Orion Plus

Extreme Pressure, Micropitting Resistant

Saturn

Rust & Oxidation Inhibited, Extreme Pressure, Micropitting Resistant

Saturn Plus

Extreme Pressure, Micropitting Resistant

Titan

Rust & Oxidation Inhibited, Extreme Pressure, Micropitting Resistant

Titan Plus

Extreme Pressure, Micropitting Resistant

Jupiter

Rust & Oxidation Inhibited, Extreme Pressure, Micropitting Resistant

Jupiter Plus

Extreme Pressure, Micropitting Resistant

4

Follow recommendations found in the Lubrication Section of this manual.

LUBRICANT TYPES

PETROLEUM-BASED LUBRICANTS (TABLES 6A &

6B)

– Industrial type petroleum-based extreme pressure

(EP) lubricants are common and readily available general

purpose gear lubricants.

SYNTHETIC-BASED LUBRICANTS (TABLES 7A & 7B)

—

Synthetic lubricants of the polyalphaolefin (PAO) type are

recommended for cold climate operation, high temperature

applications, extended temperature range (all season)

operation and/or extended lubricant change intervals. The

proper viscosity grade of lubricants is given in Table 5.

Usable temperature ranges can sometimes be widened if

specific application conditions are known.

WARNING

: Polyalkylene glycol (PAG) based synthetic

lubricants cannot be used in Planetgear units.

EXTREME PRESSURE (EP) LUBRICANTS (TABLES 6A

& 7A)

— EP lubricants are manufactures from petroleum or

synthetic base lubricants. Anti-scuff is another term used

to describe EP lubricants.

MICROPITTING RESISTANT LUBRICANTS (Tables 6B

& 7B)

— Micropitting resistant lubricants are specially

developed for surface hardened earing commonly used

in modern industrial gear drives. These lubricants contain

additives to resist formation of micropitting and other

conventional forms of gear wear.

WARNING: LUBRICANTS IN FOOD PROCESSING

INDUSTRY

— Generally, conventional gear lubricants are

classified as H2 by NSF (National Sanitation Foundation)

since they contain harmful substances and should not

be used in the food processing industry. Lubricants

registered as H1 by NSF are suitable for food processing

applications.

CLIMATE CONDITIONS

—

Ambient temperature in

immediate vicinity of gear drive is very important for

determining viscosity grade. Table 4 provides viscosity

grade selections for petroleum-based lubricants. See

Table 5 for synthetic lubricants.

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......