Owners Manual

s

Rexnord

®

Planetgear™ 7000 Series Speed Reducers

(Page 10 of 32) Sizes Neptune, Neptune Plus, Orion Plus, Saturn Plus & Titan Plus

158-170

Rexnord

January 2015

3001 W. Canal St., Milwaukee, WI 53208-4200 USA

Supersedes 11-12

Telephone:414-342-3131 Fax: 414-937-4359 www.rexnord.com

TABLE 9 — Summary of Food Grade

Lubricants and Greases

Petroleum-Based

Extreme Pressure (EP)

See Table 12

Synthetic Lubricant, Polyalphaolefin Type (PAO)

Extreme Pressure (EP)

See Table 13

Food Grade Grease

See Table 14

FOOD GRADE LUBRICANTS

Guidance for selecting petroleum-based and synthetic-

based food grade lubricants are shown below in Table 9.

For general lubrication guidelines, refer to the first part of

the “Lubrication Recommendation” section.

FOOD GRADE LUBRICANT SELECTION

PROCESS

1. Refer to Table 10 and 11 for proper lubricant viscosity

grade based on ambient temperature range.

2. Refer to Table 9 for summary of lubricant type.

3. Using proper lubricant table and viscosity grade, select

desired lubricant manufacturer and name.

4. Refer to Table 3 for approximate oil capacity to

purchase.

FOOD GRADE LUBRICANTS (TABLES 12, 13 & 14)

—

Food grade lubricants are a class of lubricants registered

as H1 by NSF (National Sanitation Foundation). They

contain base stock and additives which comply with Food

and Drug Administration Title 21 CFR 178.3570 regulations

for lubricants with incidental food contact. Base stock can

be petroleum oil or different types of synthetic lubricant.

Food grade lubricants are not the same as biodegradable

or environmentally friendly lubricants.

Rust and corrosion inhibitors used to protect gear drive

during shipment are not qualified as food grade fluids.

Flush out inhibitor oil before filling with food grade

lubricant.

Tables 12, 13 & 14 list food grade lubricants that have

performance properties meeting Rexnord specifications.

They are not exclusive recommendations but serve as a

guide for making proper lubricant selections.

CLIMATE CONDITIONS

—

Ambient temperature in

immediate vicinity of gear drive is very important for

determining viscosity grade. Table 10 provides viscosity

grade selections for petroleum-based lubricants. See

Table 11 for synthetic lubricants.

LUBRICANT CHANGES

OIL ANALYSIS REPORT (FOOD GRADE)

— Checking oil

conditions at regular intervals is recommended. Sample

oil for analysis approximately every 1,000 hours for

petroleum food grade lubricants or every 3,000 hours for

synthetic food grade lubricants. In the absence of more

specific limits, the guidelines listed below may be used to

indicate when to change petroleum or polyalphaolefin type

synthetic food grade lubricants:

1. Water content is greater than 500 ppm (parts per

million) (0.05%).

2. Iron content exceeds 150 ppm.

3. Silicon (dust/dirt) exceeds 25 ppm, above reference

sample from new oil container.

4. Copper content exceeds 75 ppm.

5. TAN (Total Acid Number) 50% increase above reference

sample from new oil container.

6. Viscosity changes more than ±15%.

7. Solid particle contamination code exceeds 25/22/18 for

particle sizes

≥

4/

≥

6/

≥

14 microns, respectively per ISO

4406.

Laboratory analysis is recommended for optimum lubricant

life and gear drive performance. Oil samples should be

taken from the oil level hole, not the drain hole.

PETROLEUM LUBRICANTS (FOOD GRADE)

— In the

absence of oil analysis, change gear oils every 6 months

or 2,500 operating hours, whichever occurs first. Change

oil more frequently when gear drives operate in extremely

humid, chemical, or dust laden atmospheres. In these

cases, lubricants should be changed every 3 to 4 months

or 1,500 to 2,000 hours. If the drive is operated in an area

where temperatures vary with the seasons, change the oil

viscosity grade to suit the temperature, refer to Table 10.

Lubricant suppliers can test oil from the drive periodically

and recommend economical change schedules.

SYNTHETIC LUBRICANTS (FOOD GRADE)

— In

the absence of oil analysis, synthetic lube change

intervals can be extended to 8,000 hours depending

upon operating temperatures. Laboratory analysis is

recommended for optimum lubricant life and drive

performance. Change lube with change in ambient

temperature, if required. Refer to Table 11.

GREASE PURGED SEALS

Whenever changing oil in the drive, purge the seals with

one of the NLGI #2 grade greases listed in Table 14.

Depending upon the degree of contamination, periodically

(at least every six months), purge the seals with one

of the NLGI #2 grade greases listed in Table 14. Purge

contaminated grease from seals by slowly pumping fresh

bearing grease through the seal,

WITH HAND GREASE

GUN

, until fresh grease flows out along the shaft. Wipe off

purged grease.

CAUTION

: Rapid regreasing with a power grease gun can

force grease inward past the seals and plug the oil drain

back system causing seal leaks.

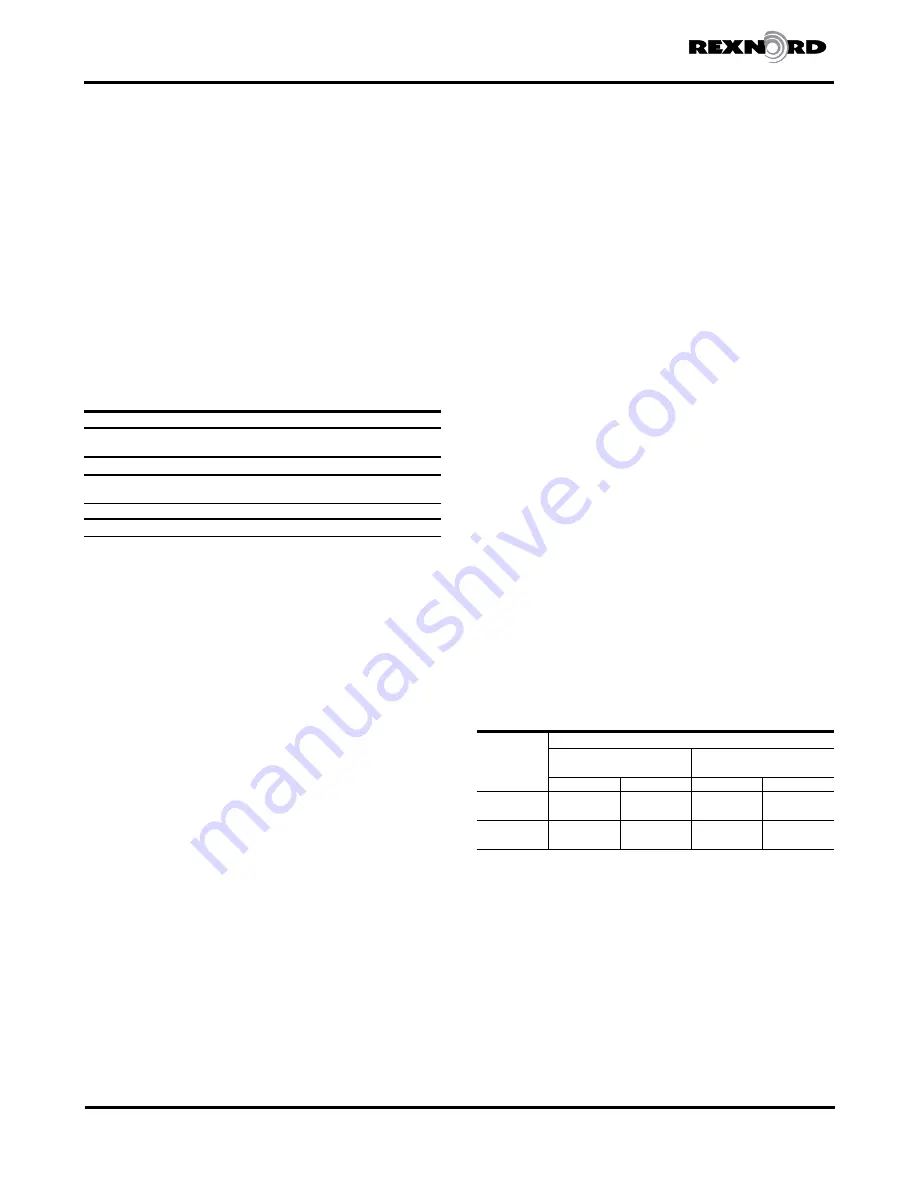

TABLE 10 — Viscosity Grade

Recommendation for Food

Grade Petroleum-Based

Lubricants

OUTPUT

SPEED

AMBIENT TEMPERATURES

+15° to +60°F

(-9° to +16°C)

+50° to +125°F

(+10° to +52°C)

ISO-VG

AGMA

ISO-VG

AGMA

RPM

BELOW 20

150

4

320

6

20 RPM

And ABOVE

150

4

220

5

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......