Rexnord

®

Planetgear™ 7000 Series Speed Reducer

s

Owners Manual

Sizes Neptune, Neptune Plus, Orion Plus, Saturn Plus & Titan Plus (Page 23 of 32)

Rexnord

158-170

3001 W. Canal St., Milwaukee, WI 53208-4200

January 2015

Telephone: 414-937-4359 Fax: 414-937-4359 www.rexnord.com

Supersedes 11-12

TABLE 15 — Socket Head Cap Screw Torque

DRIVE

SERIES

Cap Screw Torque (ft-lb)

Inupt

Output

Neptune

15

54

Neptune Plus

15

54

Orion Plus

15

54

Saturn Plus

14

54

Titan Plus

14

54

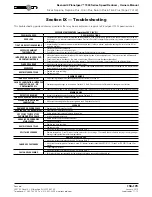

SINGLE REDUCTION

c

d

e

f

g

h

DOUBLE REDUCTION

c

d e f

g

h

i

j

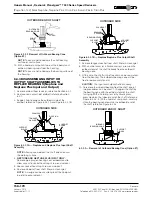

6.4.3 ADJUSTING FOR TOO LITTLE AXIAL

BEARING CLEARANCE

1. Loosen socket head cap screw on clampnut.

2. Mark the position of the clampnut.

3. Rotate clampnut 1/16” to 1/8” (1.5 to 3.1 mm) in the

counter clockwise direction from mark to loosen

clampnut.

NOTE

: The measurement given is an estimate.

4. With an arbor press or hydraulic press, push on the

clampnut end of shaft to increase the bearing axial

clearance.

5. Follow procedures in Section 6.4.1 to determine new

axial bearing clearance.

6. Repeat first 5 steps if axial bearing clearance is found

to be still too little.

6.4.4 FINAL TIGHTENING OF LOCK

SCREW ON CLAMPNUT

1. Tighten torque socket head cap screw on clampnut to

value below.

TRIPLE REDUCTION

c d e

f g h

i

j

k

l

QUADRUPLE REDUCTION

c d e f g h i jkl

11

O

13

O

O

12

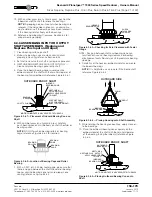

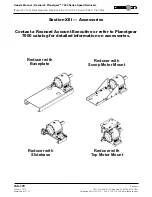

6.5 GEAR TRAIN DISASSEMBLY

Place gears in a clean dry place in the order of

disassembly. Exploded view drawings of a specific gear

train may be requested from the factory by specifying

the reducer serial number, model number, size, ratio, and

rating. To order replacement components, please give the

previously stated information about the reducer and the

items needed. Reference the following sketches for general

exploded view drawings.

NOTE

: All the gearing is stabilized at the output assembly.

Removing output assembly first may result in a difficult time

reassembling reducer. It is recommended that the input

assembly be removed first, then the gear train, and finally

the output assembly.

Single Reduction Disassembly

— Remove input assembly

(1) from maincase (5). Remove input gear (2), ring gear

(4), and last stage carrier (3). Remove output assembly (6)

from maincase.

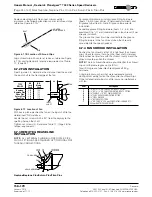

CLIP LOCATIONS

12 O’CLOCK

POSITION

Figure 6.7.1A Location of Shroud Clips

Double Reduction Disassembly

— Rem;ove input

assembly (1) from maincase (7). Remove input gear (2),

ring gear (6), first stage carrier (3), last stage sun gear

(4), and last stage carrier (5). Remove output assembly (8)

from maincase.

Triple Reduction Disassembly

— Remove input assembly

(1) from maincase (9). Remove input gear (2), first stage

carrier (3), ring gear (8), second stage sun gear (4),

second stage carrier (5), last stage sun gear (6), and

last stage carrier (7). Remove output assembly (10) from

maincase.

Quadruple Reduction disassembly

— Remove input

assembly (1) from maincase (12). Remove input gear

(2), first stage carrier (3), ring gear adapter (4), second

stage sun gear (5), second stage carrier (6), ring gear (1),

third stage sun gear (7), third stage carrier (8), last stage

sun gear (9), and last stage carrier (10). Remove output

assembly (13) from maincase.

6.6 GEAR TRAIN ASSEMBLY

The gear train can be assembled in the reverse order of

disassembly. Reference Section 6.5.

NOTE

: It is recommended that the output sub-assembly be

installed first, then the gear train, and finally the input sub-

assemble. Unit should be assemble in the vertical position,

with input shaft up.

6.7 FAN AND SHROUD INSTALLATION

6.7.1 SHROUD CLIP INSTALLATION

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......