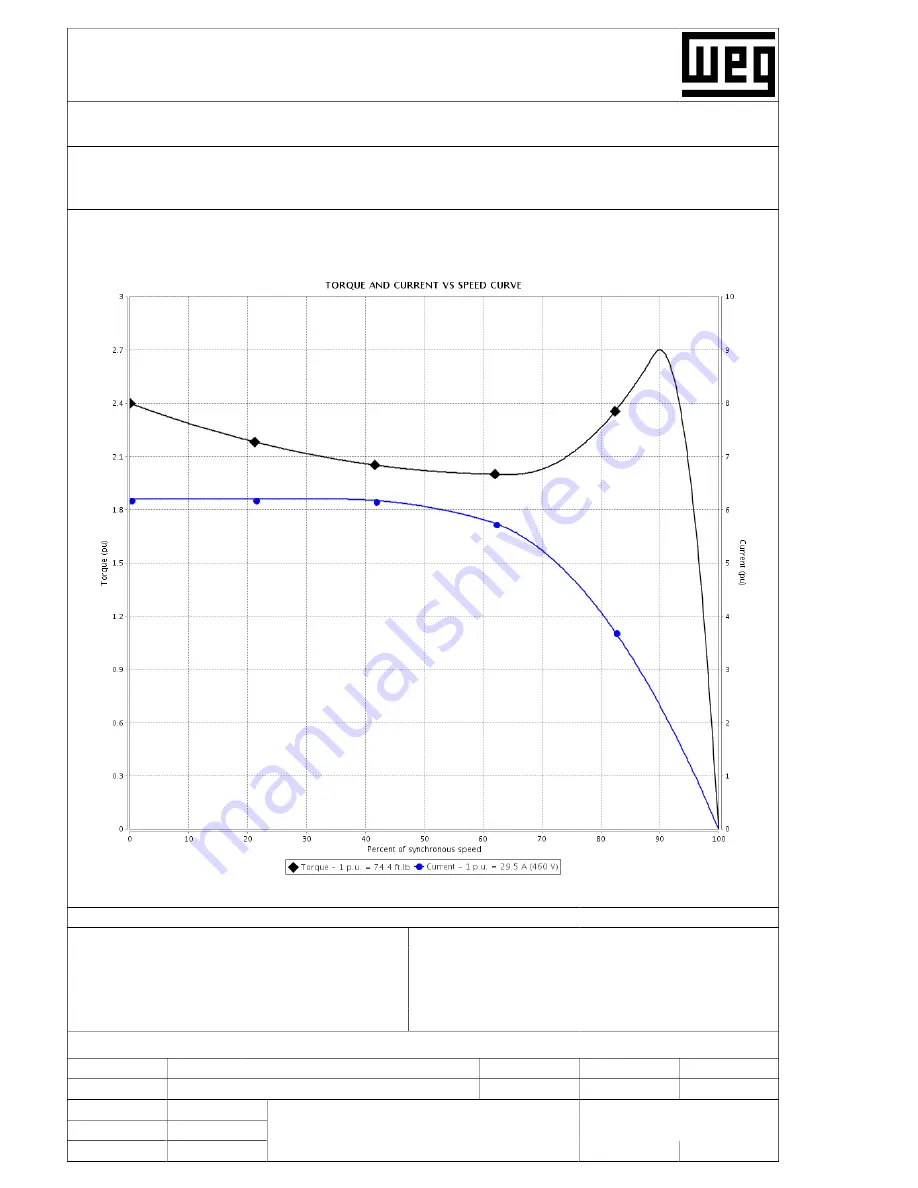

TORQUE AND CURRENT VS SPEED CURVE

Three Phase Induction Motor - Squirrel Cage

Customer

: WET Engineering (Thermal 4 LLC)

Customer reference

: CD-1261

____

Rev.

Changes Summary

Performed

Checked

Date

Performed by

Checked by

Page

Revision

Date

30/09/2020

2 / 4

This document is exclusive property of WEG S/A. Reprinting is not allowed without written authorization of WEG S/A.

Subject to change without notice

!

" #$

! % &'

%6&;7:&

,

!/!</6</!

8I9

.,"

/

5

" /809

, +

&/& /?

4

(

.1 +

&>

0-

/!

213 +

>

*

C

, *

!*

5#

2

.1

&%89&8 9

Summary of Contents for CD-1261

Page 1: ... 0 1 2121 3 4 1 5 6 ...

Page 2: ... ...

Page 3: ... ...

Page 4: ... ...

Page 5: ... ...

Page 6: ... 0 1 2 3 4 5 6 5 6 7 1 1 5 6 5 6 5 6 1 0 0 ...

Page 7: ... ...

Page 8: ... 0 1 2 0 3 0 ...

Page 9: ... ...

Page 10: ... 0 12 2 0 3 4 5 5 5 0 0 ...

Page 11: ... 6 12 0 0 7 5 5 0 8 0 8 5 0 50 9 4 12 0 0 9 4 0 9 64 0 5 0 0 1 0 0 ...

Page 12: ... 0 2 0 0 3 0 6 6 6 6 6 0 0 0 5 5 0 6 0 ...

Page 14: ... ...

Page 15: ... 0 0 1 1 2 1 1 3 0 4 5 1 0 1 0 0 2 1 2 1 0 0 0 2 1 1 1 1 1 0 0 0 1 0 0 0 1 0 1 6 1 1 ...

Page 17: ... 1 0 3 0 0 1 1 1 71 0 0 1 1 1 0 1 1 ...

Page 18: ... ...

Page 25: ... 8 ...

Page 28: ... 1 7 4 0 4 1 4 1 1 4 1 1 1 4 85 4 4 1 4 1 4 0 6 4 1 1 1 01 0 1 4 6 4 1 1 4 L 1 ...

Page 29: ... 4 ...

Page 30: ... 0 1 2 3 24 3 5 6 4 5 6 4 5 5 1 5 4 74 8 5 9 1 4 27 3 5 4 74 8 5 5 29 13 27 3 1 29 13 5 1 ...

Page 31: ... 8 8 80 1 2 3 5 6 4 5 6 4 5 5 1 5 A 9 1 B 4 27 3 888 7 8 0 B 4 C D 5 29 13 B 27 3 888 7 29 13 ...

Page 32: ... 4 24 3 5 6 4 5 6 4 5 5 4 7 M 7 4 7 N 2 0 7 2 M 0 N M ...

Page 35: ... 8 G 8 0 G 4 88 8E 1 2 3 5 6 4 5 6 4 5 5 1 4 1 4 27 3 1 088 7 5 4 1 5 29 13 H 27 3 088 7 ...

Page 36: ... E 5 ...

Page 37: ... 9 4 5 H 0 1 2034 2034 2034 2034 0 5 1 6 71 6 1 2 1 1 1 0 1 81 1 9 9 ...

Page 38: ... 1 5 1 5 1 3 05 3 1 0 1 1 6 A 6 1 A 6 B 1 6 B 6 1 1 1 6 6 6 2 9 0 6 ...

Page 39: ... 0 ...

Page 40: ... 0 0 ...

Page 42: ......

Page 43: ... 0122 3 4 5 6 4 4 4 4 5 4 4 4 4 4 7 7 4 4 6 4 4 5 5 4 5 8 8 3 5 3 5 3 5 3 5 5 ...

Page 44: ... 0 0 0 0 0 0 0 0 0 0 1 1 2 3 0 3 3 0 0 33 0 3 0 3 3 0 ...

Page 46: ... 011 2 3 3 4 3 2 5 5 6 ...

Page 47: ... 011 2 3 4 5 3 6 3 7 7 2 4 ...

Page 48: ... 00 1 2 3 4 3 5 5 5 5 5 3 1 1 2 2 6 1 1 1 5 5 7 5 5 5 5 ...

Page 49: ... 0122 3 4 5 6 7 4 8 4 4 8 4 4 8 5 5 5 5 5 5 5 5 5 5 5 5 ...

Page 50: ... 0 11 2 2 2 2 2 3 4 5 0 5 3 6 7 6 6 8 9 8 9 6 6 8 9 0 1 1 1 1 1 8 9 1 1 1 5 ...

Page 51: ... 011 2 3 4 5 4 2 2 2 6 2 6 6 3 3 3 3 3 3 3 ...

Page 53: ... 011 2 3 4 5 4 2 6 33 2 33 6 6 6 ...

Page 54: ... 011 2 3 3 3 3 4 5 4 33 2 33 6 3 3 3 ...

Page 56: ... 0122 3 4 5 6 7 8 4 4 5 8 4 4 8 9 9 9 8 4 4 4 88 8 8 8 ...

Page 57: ... 0 1 1 1 2 1 3 1 1 1 0 1 1 1 4 1 1 ...

Page 58: ... ...

Page 59: ... ...

Page 96: ...Bearing Maintenance Guide x Lubrication x Troubleshooting ...

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 165: ... 0 0 1 2 3 4 5 6 52 3 52 3 7 8 4 6 52 4 6 1 9 9 9 9 9 ...

Page 166: ... 0 5 9 9 2 2 4 6 4 6 4 6 7 8 7 8 2 4 6 4 7 8 7 8 2 4 6 4 6 52 A ...

Page 167: ... 0 0 1 2 1 2 3 4 2 1 2 3 4 ...

Page 168: ... 0 2 1 2 3 3 4 2 1 2 3 4 2 ...

Page 194: ......

Page 195: ......

Page 196: ......

Page 218: ......

Page 219: ......

Page 234: ...15 Notes Model 121 Regulators Brochure ...

Page 236: ......