Doc: I437GB04_16.docx 09/03/2016

p. 3 / 37

BRK1 switch state LED (yellow)

-

When fixed, indicates the open or closed state of line breaker 1 (BRK1). When blinking, indicates incoherence between required state of the

breaker and real state detected by the feedback signal.

BRK2 switch state LED (yellow)

-

When fixed, indicates the open or closed state of line breaker 2 (BRK2). When blinking, indicates incoherence between required state of the

breaker and real state detected by the feedback signal.

BRK3 switch state LED (yellow)

-

When fixed, indicates the open or closed state of line breaker 3 (BRK3). When blinking, indicates incoherence between required state of the

breaker and real state detected by the feedback signal.

Operating modes

OFF mode

- The equipment is off and no actions are performed in this mode. All measurement and state LED displays remain active. If the transfer device control is of the pulse

type, both open/close controls remains deactivated in OFF mode. In continuous control mode, instead, the behaviour may be selected by means of P07.n.06. Set to OFF mode

before accessing the programming menus. Press the OFF-RESET button to reset the retaining alarms providing the conditions which generated the alarm have been removed.

MAN

(manual) mode - The breakers can be controlled manually in manual mode. The breaker to be controlled can be selected on the display by pressing buttons << and >>. The

selected breaker appears surrounded by a blinking box. Press the OPEN and CLOSE buttons to change the selected breaker state.

If the closing of a breaker is manually controlled while one other breaker is still closed, the equipment will not allow the simultaneous closing.

When working with gensets, the starting and stopping of the genset can be manually controlled in the manner similar to that of the breakers. In this case, the MAN button must be

held pressed to start and stop the genset. The genset corresponding to the breaker highlighted by the blinking box will be started.

AUT

(Automatic) mode - In automatic mode, the equipment autonomously carries out the opening and closing operations of the breakers and to start and stop any gensets. When

the priority line is out of limits for a time higher than the set delay (green line presence LED off), the device disconnects the load from the priority line and connects to the

immediately next priority line, starting of the genset (if applicable) and managing the operation and interlock times. The equipment can be programmed to open the priority line

breaker either before or after the alternative line is made available

.

When the priority line return within the limits, the device switches the load back onto it and runs the genset cooling cycle, if needed. The automatic return to priority lines can be

locked. If possible and necessary, the load can be transferred with closed transition, i.e. with the two power sources momentarily in parallel. There are very many automatic

operating cycles which vary according to the defined system configuration (14 possibilities) and according to the type of transfer devices used (motorised breakers, motorised

changeover switches or contactors). Refer to the possible system configurations and the respective truth tables which describe the system behaviour in automatic mode.

Note: The use of

closed transition

function is not compatible with compliance with IEC / EN 60947-6-1.

TEST

mode - In test mode, the equipment starts the gensets, if present, to test their operation. If the TEST button is held pressed for 5 seconds, the equipment will run a cycle

which simulates loss of the priority line anticipated by a notification message with consequent load transfer.

Caution

: this will momentarily interrupt power supply to the load. Lack

of the secondary line is then simulated with the further transfer to the third line, if present. Two minutes later, the cycle will go back to the secondary line and finally to the main line

in sequence. During this cycle, the message

SIMUL

appears on the display with a countdown to indicate TEST progress. The simulation cycle may be started on the

command

menu

.

Energising the equipment

ATL900 has two power supplies: 100-240VAC or 12-24-48VDC. Priority is given to the AC power if both are present at the same time.

The equipment is normally set to the OFF mode when it is switched on. Modify parameter P01.03 in the

M01 Utility

menu if the operating mode selected before switch-off must

be maintained.

If may be powered at 12 or at 48VDC but the battery voltage must be set correctly in the

M04 battery

menu otherwise a battery voltage alarm will be generated.

All LEDs blink during the energising procedure to check operation.

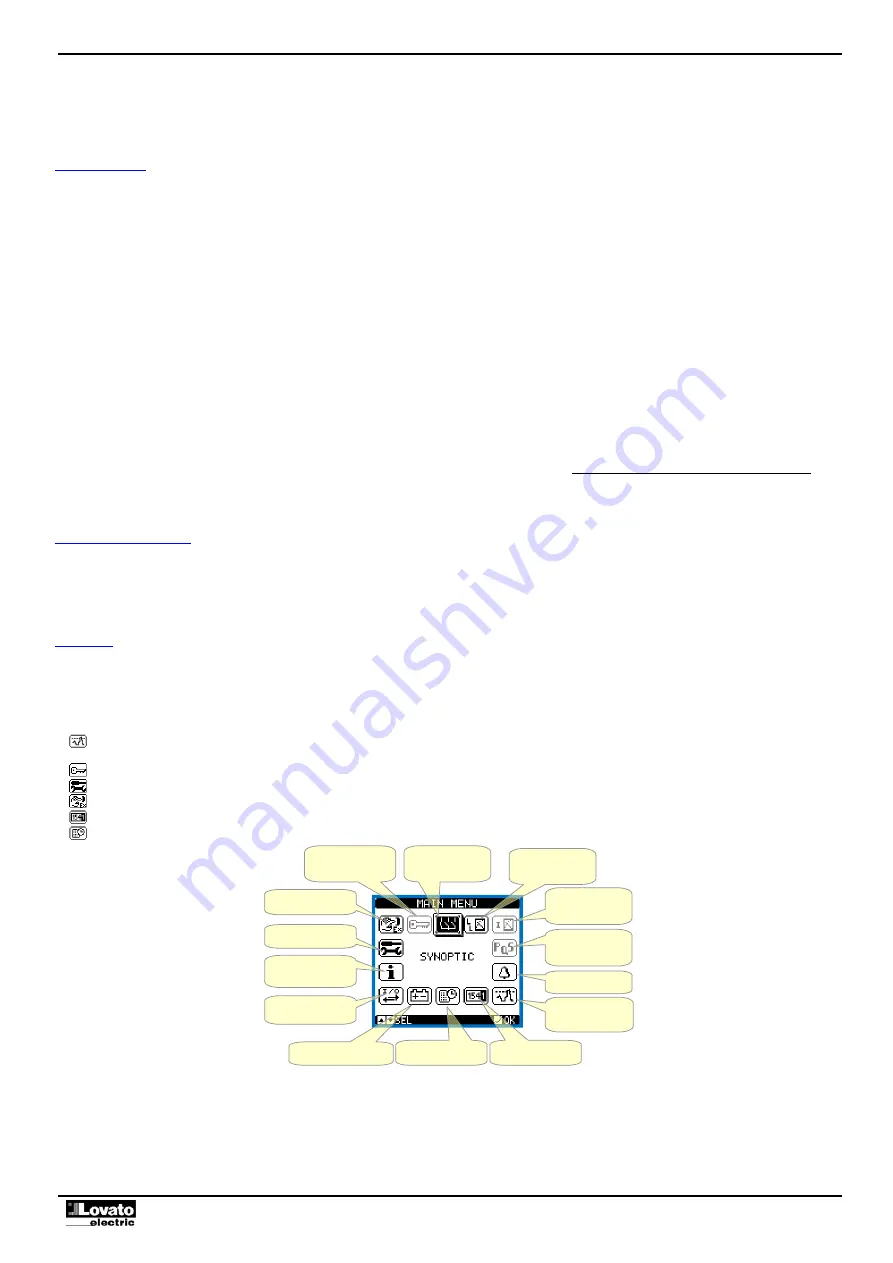

Main menu

The main menu consists of a set of graphic icons which allow rapid access to measurements and settings.

Press button

starting from the normal measurement view. The rapid menu appears on the display.

Press

◄

or

►

to turn clockwise/anticlockwise and select the required function. The selected icon is highlighted and the message in the middle of the display indicates the

description of the function.

Press

to activate the selected function.

If some functions are not available, the corresponding icon will be deactivated, i.e. will greyed out.

etc. - Operate as short cuts which allow to speed up access to pages for displaying measurements, going directly to the selected measurement unit, from which it is

possible to move forwards and backwards are usual.

- Setting the numeric code which allows to access protected functions (setting parameters, executing controls).

- Parameter programming access point. See the dedicated chapter.

- Control menu access point, where authorised users can perform a number of resetting and restoring operations.

- Access point to statistic operating data supplied by the controller.

- Access point to the events list.

Control thresholds

Statistics

Events log

Battery state

Input/output state

Information page

Setup parameters

Control menu

Password entry

Synoptic

Voltages

Currents

Powers

Alarms