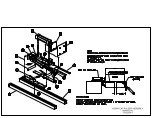

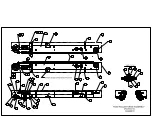

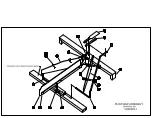

ASSEMBLY NO.:

C622920

ASSEMBLY NAME:

HOPPER FRAME ASSEMBLY

MACHINE TYPE:

CASEFORM 40

ITEM

QTY

PART NO. DESCRIPTION

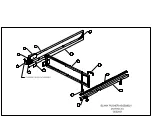

1

1

C622723

HOPPER DRIVE SIDE BOTTOM BEAM

2

1

B622563A

CONNECTING PLATE

3

1

C622724

HOPPER DRIVE SIDE TOP BEAM

4

1

B622564A

SUPPORT SHAFT

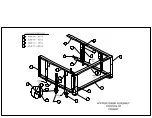

5

4

C622716

HYDRAULIC LIFT CYLINDER MOUNT PLATE

6

4

204738-2

HYDRAULIC CYLINDER

7

4

C622717

HEIGHT ADJUSTING BRACKET

8

1

C622737-1

HOPPER REAR OUTSIDE LEG

9

1

C622339C

HOPPER FRAME REAR BEAM

10

1

204738-1

HYDRAULIC PUMP

11

1

C622718-1

HOPPER INSIDE REAR LEG

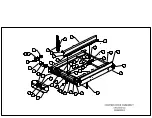

12

16

MS6-M5X18

M5 HEX HEAD BOLT X 3/4” LG.

13

16

MW2-3

M5 LOCK WASHER

14

16

MW1-3

M5 FLAT WASHER

15

1

C622721

HOPPER FIXED SIDE BOTTOM BEAM

16

1

C622722

HOPPER FIXED SIDE TOP BEAM

17

1

C622419B-1

HOPPER FRONT SPACER PLATE

18

4

MS6M10X4

0

M10 X 1.5 HEX HEAD BOLT

19

1

C622736

HOPPER REAR BOTTOM BEAM

20

1

C622735-1

HYDRAULIC HOSE GUARD

21

1

40-004

HYDRAULIC HOSE

22

1

40-004-26

HYDRAULIC HOSE

23

1

40-004-50

HYDRAULIC HOSE

24

1

40-004-78

HYDRAULIC HOSE

25

1

40-004-105

HYDRAULIC HOSE

N/S 5 40-030 RUBBER GROMMET

N/S 1 PA600023 HOPPER HEIGHT INDICATOR

Summary of Contents for CASEFORM 40

Page 25: ......

Page 27: ......

Page 29: ......

Page 31: ......

Page 33: ......

Page 35: ......

Page 37: ......

Page 39: ......

Page 41: ......

Page 43: ......

Page 45: ......

Page 47: ......

Page 49: ......

Page 51: ......

Page 53: ......

Page 55: ......

Page 57: ......

Page 59: ......

Page 61: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......