31

R

Section 7

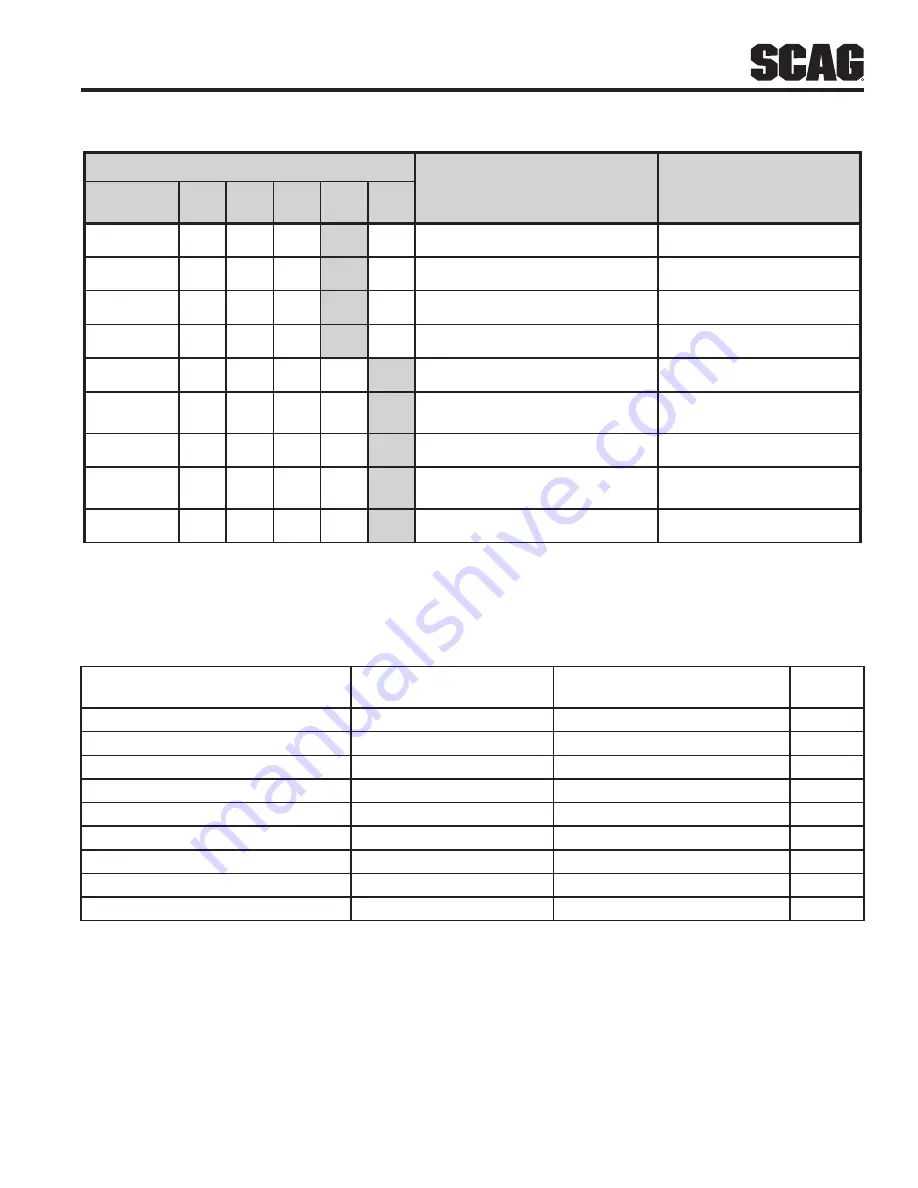

MAINTENANCE CHART - RECOMMENDED SERvICE INTERvALS (CONT'D)

HOURS

PROCEDURE

COMMENTS

BREAk-IN

(FIRST 10)

8

40

100

200

500

X

Apply grease to fittings

See paragraph 7.2

X

Check hardware for tightness

X

Change engine oil filter

See paragraph 7.4

X

Check hydraulic oil level

See paragraph 7.3

X

Replace engine fuel filter

See paragraph 7.5

X

Drain hydraulic system and replace

hydraulic oil

Use SAE 20W50 Motor Oil.

See paragraph 7.3

X

Replace hydraulic oil filter

See paragraph 7.3

X

R e p l a c e c u t t e r d e ck g e a r b ox

lubricant

See paragraph 7.11

X

Change coolant

See paragraph 7.11

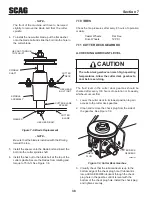

LUBRICATION

7.2

GREASE FITTING LUBRICATION CHART (SEE FIGURE 7-1)

LOCATION

LUBRICATION INTERvAL

LUBRICANT

NO. OF

PLACES

1 Caster Wheel Pivot *

500 Hours/Yearly

Chassis Grease

2

2 Caster Wheel Bearings

100 Hours/Monthly

Chassis Grease

2

3 Cutter Deck Bellcranks

100 Hours/Bi-Weekly

Chassis Grease

4

4 Cutter Deck Pusharms

100 Hours/Bi-Weekly

Chassis Grease

2

5 PTO Spindle

40 Hours/Weekly

+Lithium MP White Grease 2125

1

6 Cutter Deck Spindle

40 Hours/Weekly

+Lithium MP White Grease 2125

3

7 Brake Handle

200 Hours/Monthly

Chassis Grease

1

8 Cutter Deck Drive Shaft U-Joints

200 Hours/Monthly

Chassis Grease

2

9 Cutter Deck Drive Shaft Slip Sleeve

40 Hours/Weekly

Chassis Grease

1

+ Compatible Greases:

Mobilix #2 found at Mobil Service Stations

Ronex MP found at Exxon Service Stations

Super Lube MEP #2 & Super Stay-M #2 found at Conoco Stations

Shell Alvania #2 found at Shell Service Stations

Lidok EP #2 found at industrial shops

Timken Lithium Multi-Use #2 found at industrial shops

* PROCEDURE: Remove grease cap, part number 481559. Remove plug, part number 482028-01, and install grease

zerk. Apply grease to the fitting until new grease appears at the top of the caster extension. Remove the grease

zerk and reinstall the plug. Reinstall the grease cap. Special tool, part number 47007, is recommended for use in the

installation of the grease cap.