14

4. Most people can get good results by following steps 1 through 3, so this

step is

optional

. If you want to make an extra effort to be absolutely sure

that your selected location will work under all conditions, make a test

run with the boat on plane and observe the bottom signal. You'll need to

figure some way to prop the transducer into position while you make

your test run. (A brick or two might be sufficient to hold it in place.)

5. When you're satisfied with a location, mark it and proceed with

the installation.

Shoot-thru-hull Installation

If you are installing the transducer on a hull with floatation material

sandwiched within the hull, refer to the text "Hulls With Flotation

Materials" beginning on page 11.

1. Make sure the area is clean, dry and free of oil or grease, then sand

both the inside surface of the hull and the face of the transducer with

100 grit sandpaper. The sanded hull area should be about 1-1/2 times

the diameter of the transducer. The surface of the hull must be flat

so the entire transducer face is in contact with the hull prior to

bonding. After sanding, clean the hull and transducer with rubbing

alcohol to remove any sanding debris.

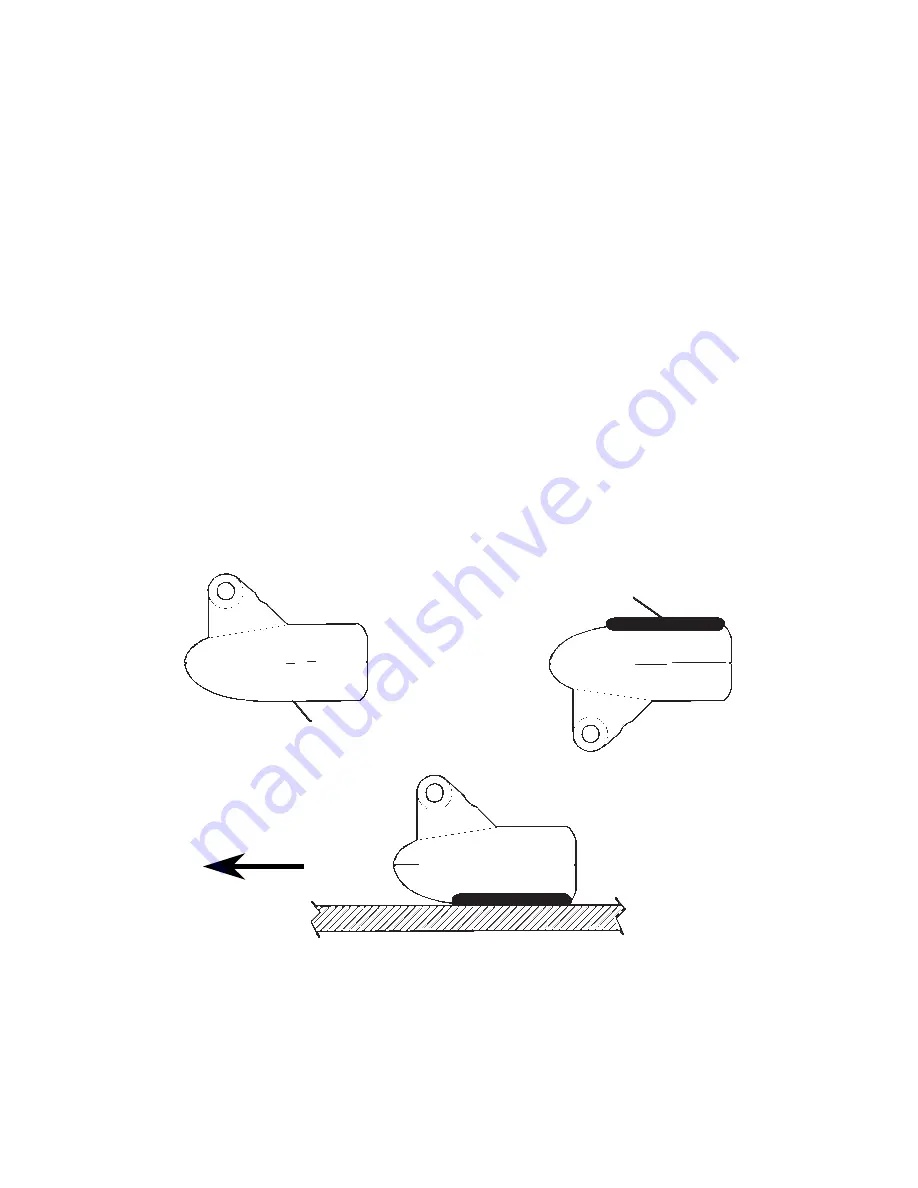

Epoxy transducer to hull.

WARNING:

Use

only

the epoxy available from LEI. It has been

formulated to work with these installation procedures.

Other epoxy types may be too thin or may not cure to the

right consistency for optimum transducer performance.

Spread epoxy here

Sand this

surface

(unit's

Orient the Skimmer

with the nose facing

the bow of the boat.

To bow