Screen Lift 750 Trolley Mount

9

The warranty is only valid in so far as the equipment has been used and maintained

correctly and has not been tampered with.

Violent treatment will invalidate the warranty.

During operation if the unit makes any unusual noises or smells turn off the power sup-

ply at the mains immediately.

Continuous use maximum period 2 minutes.

Maximum use 10% (6 minutes in any hour).

Ambient temperature range +5deg C to +40 deg C.

The noise produced by the unit when static is silent which represents 99% of the time

in use.

The noise produced by the unit when moving is consistent with other office equipment

and would by comparison be rated as low.

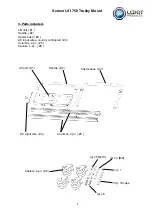

8. Screen Lift Kit Contents

1nr 2.5mm long leg Allen key square end

1nr 3.0mm long leg Allen key ball end

1nr 4.0mm long leg Allen key ball end

1nr 6.0mm long leg Allen key ball end

1nr 6.0mm equal leg Allen key or tee bar square end

3nr cable ties

4nr M6 x 16 button head screws (4 for plasma screen)

4nr M6 x 12 (for horizontal mount bars)

4nr M6 x 25 button head screws (alternative for plasma screen)

8nr M6 washers 20mm diameter

4nr M8 x 20 button head screws for plasma screen

4nr M8 x 40 button head screws (longer for plasma screen)

2nr security clips

2nr M6 x 50 button head security screws

16 grey buttons

Supplementary instructions.

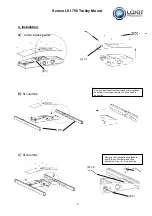

9. Bracket Pack Contents

1nr Top rail

1nr Bottom rail

2nr Vertical brackets 200mm centres