2 7

TREA

TMENT

HEADS

7

→

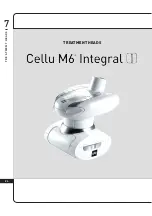

DESCRIPTION OF THE KEYMODULE

TM

The Keymodule is the interchangeable lower

section of the Ergodrive

TM

head. It comprises

the motorised rollers and sealing valves.

You have one Keymodule (KM80).

Installation:

The Keymodule is designed to be compatible

with the treatment head.

Attach the Keymodule as shown below.

To remove the Keymodule release the latches.

SEALING VALVES

ELECTRICAL

CONTACTS

LOCKING CLIPS