62

63

configuration and maintenance menus

6 configuration and maintenance menus

>

6.9c Functional teStS taB (cont.)

Vacuum screen (cont.)

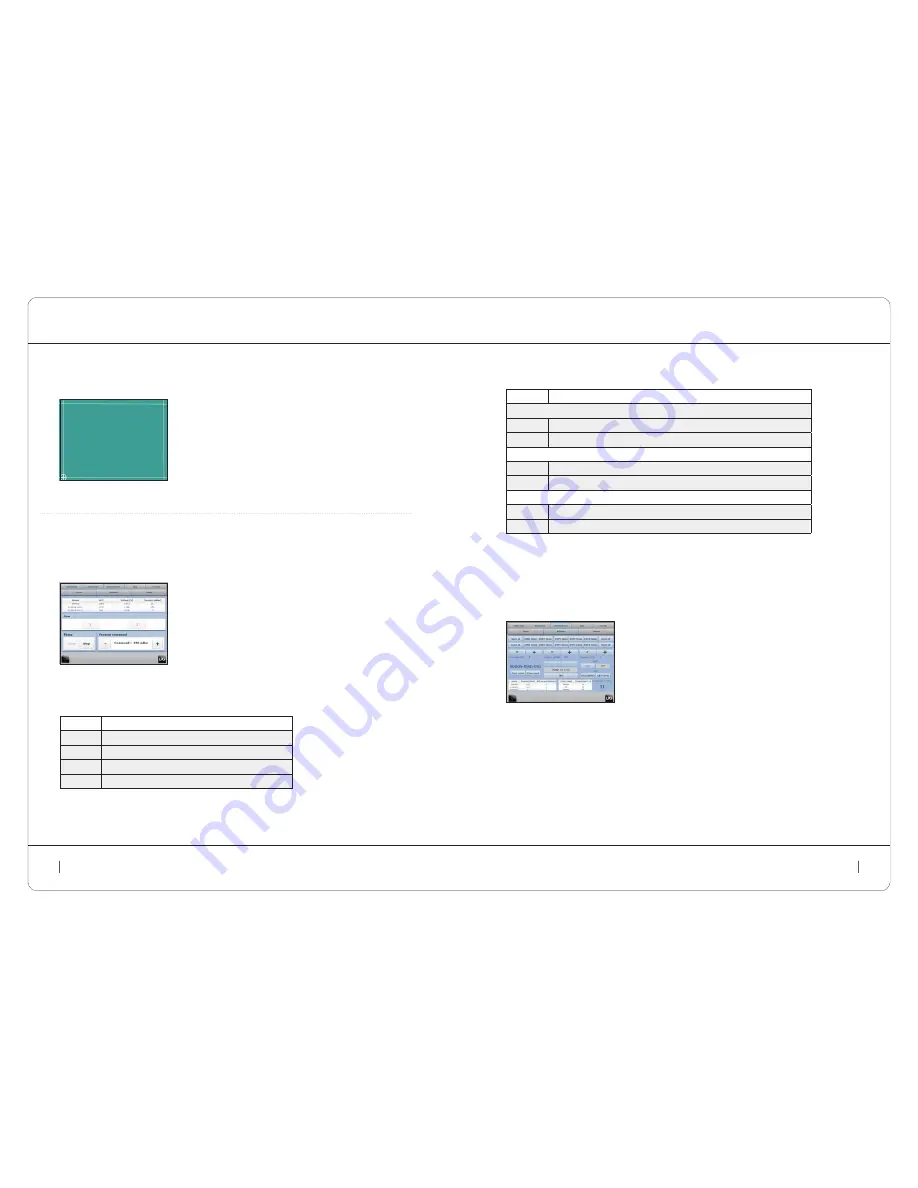

functional tests screen

Button

action

ARM SELECTION

1

Select Arm 1 to regulate the vacuum pressure

2

Select Arm 2 to regulate the vacuum pressure

PUMP START UP

Start

Start the regulation pumps

Stop

Stop the regulation pumps

PRESSURE SETTING

-

Decrease the pressure setting by 50 mBar

+

Increase the pressure setting by 50 mBar

The arm selection can only be changed when the pumps are off.

The pressure control is carried out by the external sensor (External Arm 1 or External Arm 2)

The pressure value measured should correspond to the specified pressure setting by ±10%

This test can only be carried out if the arm hose is in correct working condition, without blockage or leakage.

Button box screen (according to software version)

The ‘button box’ screen allows testing of various functions simultaneously. These include:

Solenoid valves

•

Setting parameters (frequency, cycle rate, pressure)

•

Pump pressure

•

Light band

•

Fan and temperature

•

This screen displays a large quantity of buttons and information.

Each part is described in full on the following pages.

cont .

>

configuration and maintenance menus

6 configuration and maintenance menus

>

6.9b unitary teStS taB (cont.)

Hmi Screen (cont.)

The calibration button allows access to the touch-screen calibration screen

6.9c Functional teStS taB

Functional tests on the unit may be carried out from these maintenance screens.

Vacuum screen

The correct function of pressure regulation for each arm can be checked from this screen.

It can be used to detect faulty sensors or leakages.

The pressure values are limited at approximately 900mBar

for the external sensors and 1150 mBar for the internal

sensors.

This screen is divided into 4 parts

Measurements table

•

Arm selection

•

Pumps start-up

•

Regulation command

•

touchscreen calibration screen

regulation tests screen

column

description

Sensor

Pressure sensor used

ADC

Value returned by the Analoque/Digital Converter

Voltage

Voltage corresponding to the value returned by the ADC

Vacuum

Vacuum pressure corresponding to the voltage

Measurement results table

cont .

>

The calibration is carried out by pressing for a few seconds

(preferably with a stylus type object) the point indicated

onscreen by a cross.

Four points are required for correct calibration. The calibration

of each point has a time limit (the remaining time is indicated

in the bar at the bottom of the screen). The calibration is

automatically cancelled when the time limit is exceeded.