L7C Series AC Servo Drives Quick Start Guide

Page 9 of 60

L7C Servo Drives Quick Start Guide – 1st Ed. Rev A, 11/29/2021

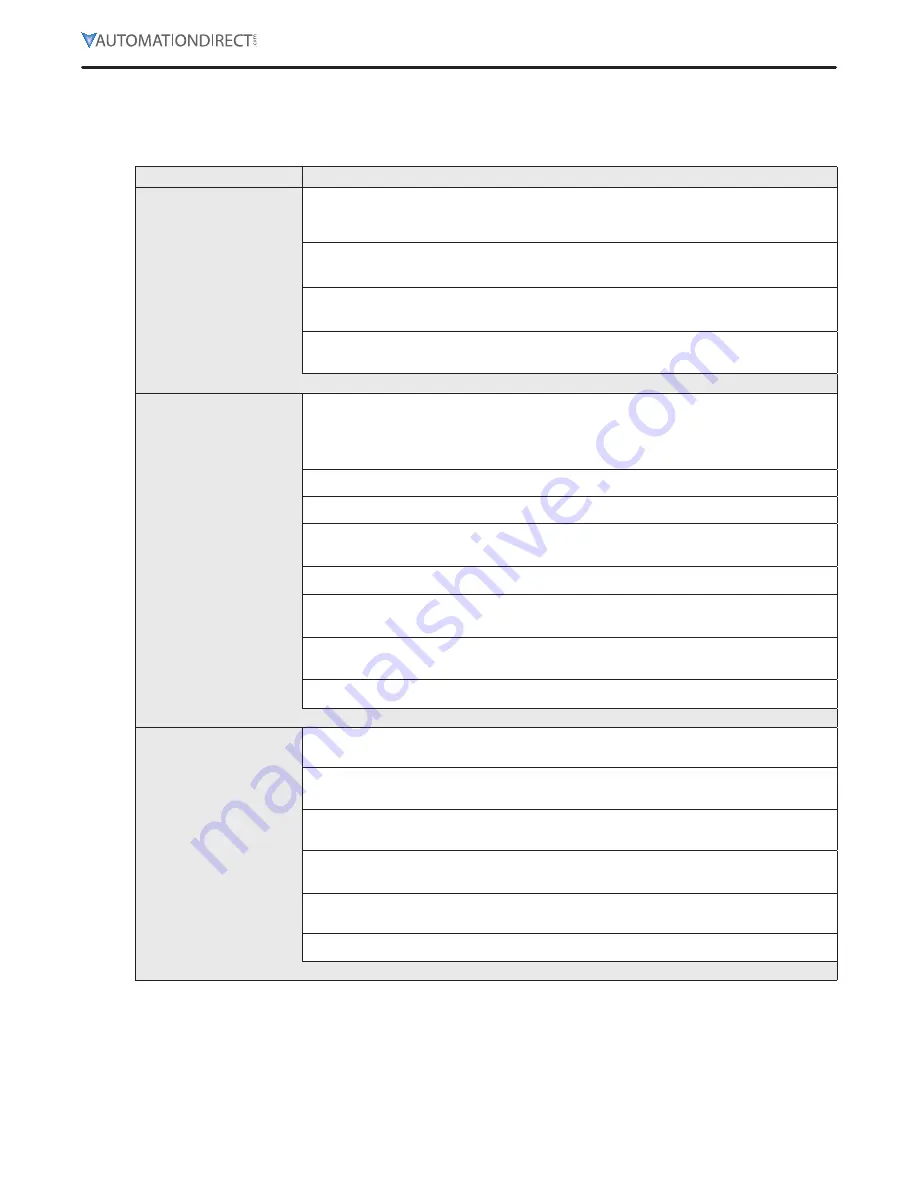

Basic Inspection

Perform periodic inspections to maintain your equipment, as well as inspections before operation of

the servo and motor.

Inspection

Task

General Inspection

Periodically check to confirm the screws are securely tightened This includes the screws in

the servo drive, the connection screws between the motor shaft and the machine, and the

connection screws between the terminal block and machine

Prevent oil, water, metallic particles, and other foreign matter from entering the control box

or ventilation equipment Protect the servo drive from any drill cuttings

If the control box is installed in a location where dust or harmful gas are present, ensure the

dust or harmful gas cannot enter the control box

Make sure to wire encoders and other devices in the proper sequence to avoid sudden

unintended acceleration or damage to the motor

Inspection before

operation (power OFF)

To avoid electric shock, connect the ground terminal of the servo drive to the ground

terminal of the control box If wiring must be added or modified, wait at least 10 minutes

after disconnecting the servo drive from the power supply or discharge the electricity with a

discharge device

Isolate the wires at the wiring terminal

Make sure the wiring is correct to avoid damage or any abnormal operation

Check for and remove any electrically conductive objects, including metal sheet and screws,

or flammable objects inside or near the servo drive

Make sure the emergency stop switch is OFF

To ensure the electromagnetic brake works, make sure the stop and circuit breaker functions

are working properly

Reduce the electromagnetic interference if there is electromagnetic interference with the

peripheral devices

Make sure the external voltage level of the servo drive is correct

Inspection before

operation (power ON)

The encoder cable should be protected from excessive stress - make sure the cable is not

worn or stretched

Contact AutomationDirect if the servo motor vibrates or makes unusual noise during

operation

Make sure the parameter settings are correct Different machines have different

characteristics Adjust the parameters according to the characteristics of each machine

Reset the parameters when the servo drive is in the Servo OFF status to avoid possible

malfunction

If there is no contact noise or other abnormal noise when the relay is operating, contact

AutomationDirect

Contact AutomationDirect if the power indicator or LED display does not function properly