5 - 28

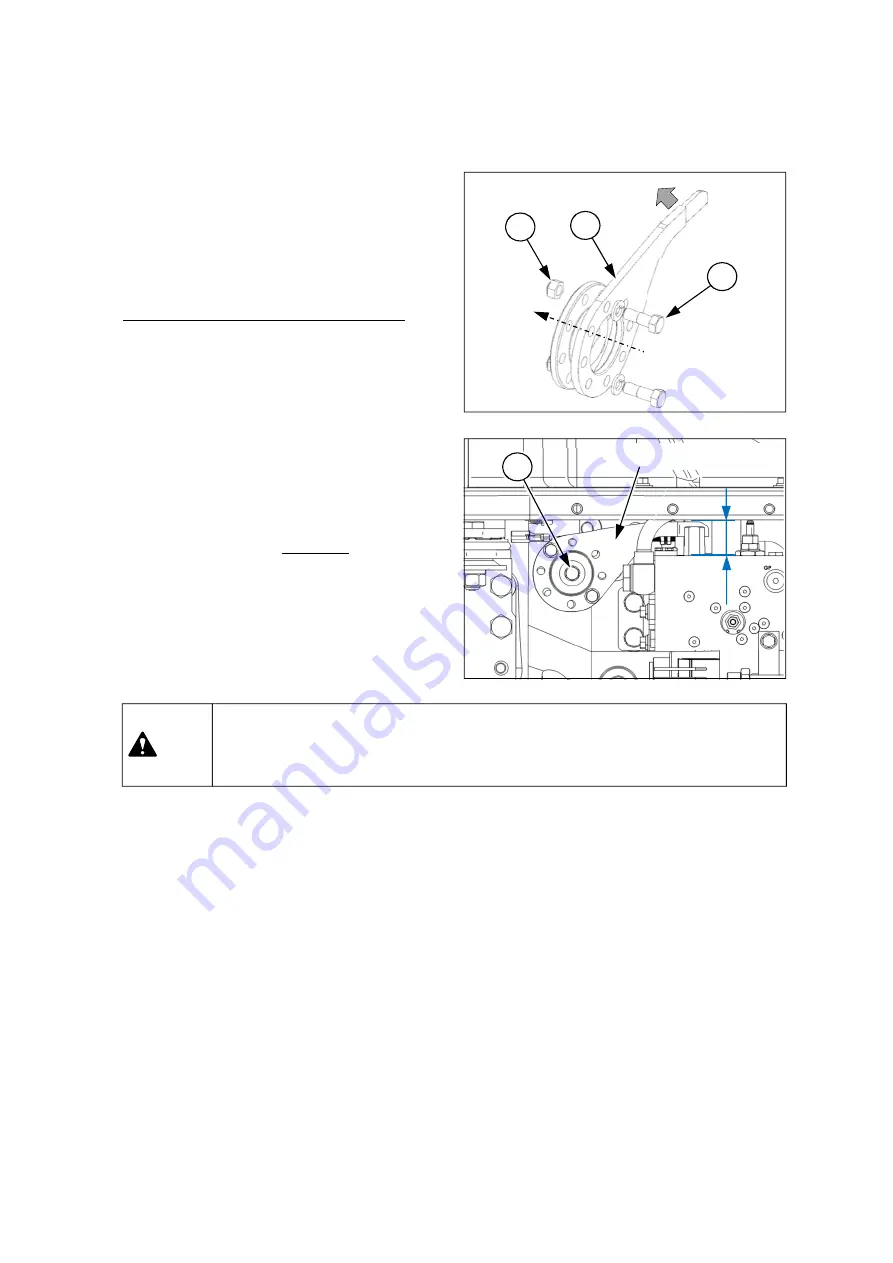

Unscrew the two bolts

④

and rotate the clutch

arm

③

counter-clockwise by 2.5 degrees.

Assemble the two bolts

④

with washers and nuts

⑤

into the next assembly holes counter-

clockwise from the previous attached holes.

Tighten the two bolts.

Tightening torque: 34~39 N.m (25~29 lb-ft)

Note: This rule must be adapted when you

adjust the clutch arm next times.

3

4

5

Clutch arm assembly

2

“H”

▶

If the clutch arm assembly is not adjusted on time, it may cause a rapid/earlier

clutch disk abrasion and damage of the synchro-mech gears.

Caution

Assemble the clutch arm assembly to the tractor

in the reverse order of disassembly, and tighten

the bolt

②

.

Check if the height(“H”) of the clutch arm from

the valve block is about 35~36mm after

adjustment.

New assembly hole

Counter-clockwise

Summary of Contents for MT342

Page 1: ...LS TRACTOR OPERATOR S MANUAL MT342 MT347 MT352 MT357 Stage...

Page 2: ......

Page 46: ...1 32 2 9 6 11 3 1 Roll Bar 5 10 7 8 4 12 13 14 16 18 17 10...

Page 62: ...1 48...

Page 76: ...2 14...

Page 180: ...4 42...

Page 248: ...5 68...

Page 258: ...7 2 Unit mm Roll bar type Front tires 9 5 16 6PR Rear tires 13 6 24 8PR...

Page 263: ......

Page 264: ...P NO 52132436 05 DATE 20220000...