5 - 43

5-12. Every 1000hr or 1-year check

(2) Checking Nozzle injection pressure

Contact your authorized local dealer for check.

Normal injection pressure (Common rail): 180MPa (26100 psi)

▶

Only qualified service personnel should perform this maintenance. Contact your

authorized local dealer for this maintenance. Operation of engines with incorrect

valve lash can reduce engine efficiency, and also reduce engine component life.

Caution

▶

Ensure that the engine can not be started while this maintenance is being

performed. To help prevent possible injury, do not use the starting motor to turn the

flywheel.

▶

Hot engine components can cause burns. Allow additional time for the engine to

cool before measuring/adjusting valve lash clearance.

Warning

▶

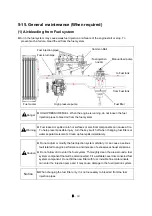

Do not allow dirt to enter the fuel system. Thoroughly clean the area around a fuel

system component that will be disconnected. Fit a suitable cover over disconnected

fuel system component.

▶

If a fuel injector is suspected of operating outside of normal parameters, it should

be removed by a qualified technician. The suspect fuel injector should be taken to

an authorized agent for inspection.

Caution

▶

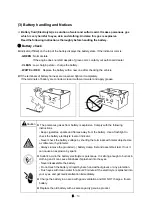

Fuel leaked or spilled onto hot surfaces or electrical components can cause a fire.

▶

Work carefully around an engine that is running. Engine parts that are hot, or parts

that are moving, can cause personal injury.

▶

Make sure that you wear eye protection at all times during testing. When fuel

injection nozzles are tested, the high pressure test fluid can pierce the skin and

cause serious injury to the operator. Always keep the tip of the fuel injection nozzle

pointed away from the operator and into the fuel collector.

Warning

(1) Adjusting Engine valve clearance

Valve clearance

Contact your authorized dealer to check the

valve clearance.

Normal: 0.25mm (0.0098 in)

If the gap is large, the valves can make a loud

tapping noise and if the gap is too small, the

engine output power may be reduced due to

leakage of compressed air.

Summary of Contents for MT342

Page 1: ...LS TRACTOR OPERATOR S MANUAL MT342 MT347 MT352 MT357 Stage...

Page 2: ......

Page 46: ...1 32 2 9 6 11 3 1 Roll Bar 5 10 7 8 4 12 13 14 16 18 17 10...

Page 62: ...1 48...

Page 76: ...2 14...

Page 180: ...4 42...

Page 248: ...5 68...

Page 258: ...7 2 Unit mm Roll bar type Front tires 9 5 16 6PR Rear tires 13 6 24 8PR...

Page 263: ......

Page 264: ...P NO 52132436 05 DATE 20220000...