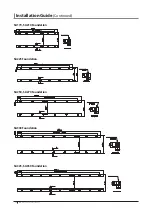

Typical Starter Diagram-2 Compressor

VP

107

D24

Z

Y

X

W

V

U

R11

S11

R2

PB

106

D24

T2

R2

380V

TR

R02

T2

220V

700V

A

R01

T01

NFB2

10A

S

2M

1M

S

2M

164

2M

161

158

1M

S

S0

T0

R0

T1

S1

R1

600V

NFB1

301

302

303

88 F4

F4

88

U42

V42

F3

V41

U41

W42

W41

51

FM

4

U31

V31

U32

V32

F1

88

V21

V22

F1

W11

51

W12

U22

U21

F2

W22

W21

51

F2

88

FM

3

FM

2

V11

U11

V12

U12

FM

1

W32

W31

51

F3

KM1

KM2

KM3

231

230

C2

C1

R2

G

IT

CT

AI3

T2

232

88

F1

88

F2

88

F3

F1

51

F2

51

F3

51

R2

T2

171

172

173

233

88

F4

F4

51

174

3PH 380V

AC 50/60HZ

M

AIN POWER SUPPL

Y

TO C

ONTROL

PANEL

R02

R02

R02

R2

R2

303

302

301

R2

231

232

KM1

KM3

KM2

230

233

MP

VP

106

107

D24

106

107

D24

E

R2

G

AI3

G

AI3

G

AI3

R2

R2

301

301

302

302

303

303

230

230

231

231

232

232

233

233

ST

AR

TER PNL

CONTROL PNL

BOD

Y

WIRING

ST

OP SGL.

EMERGERNCY

ABNORM

AL SGL.

MO

TOR&POWER

TR

ANSDUCER SGL.

CURRENT

CONT

AC

TOR SIGNAL

COOLING F

ANS SIGAL

FROM C

ONTROL P

ANEL

TO C

ONTROL P

ANEL

T2

T2

T2

R2

R2

R2

POWER

CTRL. P

ANEL

3. FROM/T

O C

ONTROL P

ANEL.

2.

THESE P

AR

TS ARE L

OC

ATED ON CHILLER BOD

Y.

Not

e

1.

THESE P

AR

TS ARE L

OC

ATED IN C

ONTROL P

ANEL.

ELEC

TRIC

AL P

AR

T LIST

1

1M,2M,S

M

AGNE

TIC C

ONT

AC

TOR

2

NFB1

MOLDED C

ASED CIRCUIT

BREAKER

3

NFB2

NO FUSE BREAKER

4

TR

TR

ANSFORMER

700V

A

5

PB

EMERGERNCY ST

OP SWIT

CH

6

MP

MO

TOR PRO

TEC

T RELA

Y

7

VP

POWER PRO

TEC

TOR

8

IT

AMPERE

TR

ANSDUCER

9

CT

CURRENT

TR

ANSFORMER

10

88F1-4

M

AGNE

TIC C

ONT

AC

TOR

11

51F1-4

THERM

AL RELA

Y

12

FM1-4

COOLING F

AN

13

FA

N

COOLING F

AN

14

KM1-3

AUX.RELA

Y C

ONT

AC

T

FROM C

ONTROL

PNL

T11

11

14

12

L2

L3

L1

1

4

3

2

5

6

C

OMP MO

TOR

M2

M1

N

L

L1

MP

L3

L2

FAN

101

102

100

103

105

106

104

107

CO

M

R21

T21

FS

SW

D24

F1/5A

E

E

R22

223

220

222

221

PU

CO

M

CO

M

CO

M

D24

CH

XC

201

200

RS

110

111

CO

M

D24

OUT

C0

Y0

Y1

Y2

Y3

Y7

Y6

Y5

DVP

-16SP

Y4

S/S

X0

X1

X2

X3

X4

X5

X6

X7

IN

24V

0V

G

N

L

DVPPS02

TP04

-

+

G

0

24

RS

-485

HP

LP

OL

OP

MP

EKD

VP

F.G

1

T2

R2

HQ

R20

T20

MC

CB

10A

FA

N

KM2

340

POWER 1PH 220V

AC 50/60HZ

2

3

4

V3

V1

V2

V0

N.F

.

T21

R21

E

E

E

402

401

403

404

KM2

XC

406

405

D24

101

102

D24

SW

RS

D24

103

PU

CH

T2

T2

T2

R2

R2

106

MP

107

D24

106

107

D24

R2

G

AI3

AI3

G

G

AI3

VP

E

1.

2.

4.

3.

ELEC

TRIC

AL P

AR

T LIST

1

FS

FL

OW SWIT

CH

2

PU

CHW PUMP INTERL

OCK

SGL

FROM USER

3

SW

REMO

TE ST

AR

T/ST

OP

SIGNAL

FROM USER

4

RS

REMO

TE RESE

T SIGNAL

FROM USER

5

VP

POWER PRO

TEC

T RELA

Y

6

MP

MO

TOR PRO

TEC

T RELA

Y

7

HP

HIGH PERSSURE SWIT

CH

8

LP

LOW PRESSURE SWIT

CH

9

OL

OIL LE

VEL SWIT

CH

10

OP

OIL DIFF

. PRESSURE

SWIT

CH

11

TE01

ECHW

TEMPER

ATURE

SENSOR

PT100

12

TE02

LCHW

TEMPER

ATURE

SENSOR

PT100

13

TE03

FIN

TEMPER

ATURE SENSOR

PT100

14

TE04

SUC

TION

TEMPREA

TURE

SENSOR

PT100

15

TE05

EXHA

UST

TEMPREA

TURE

SENSOR

PT100

16

EP

EV

AP PRESSURE

TR

ANSMIT

TER

17

CP

COND PRESSURE

TR

ANSMIT

TER

18

IT

CURRENT

TR

ANSDUCER

SIGNAL

19

KM1-3

AUX.RELA

Y (

CONT

AC

TOR)

20

CH

AUX.RELA

Y (

CHW PUMP)

21

XC

AUX.RELA

Y (F

AUL

T)

22

PY

SPR

AY LIQUID SOLENOID

VAL

VE

23

ET

S

ELEC

TRONIC

EXP

ANSION

VAL

VE

24

SV1

SOLENOID

VAL

VE 25%

25

SV2

SOLENOID

VAL

VE 75%

26

SV3

SOLENOID

VAL

VE 50%

27

HQ

OIL HEA

TER

28

FA

N

COOLING F

ANS

29

MC

CB

MOLDED C

ASE CIRCUIT

BREAKER

30

N.F

.

NOISE FIL

TER

31

F1-2

FUSE

32

V0-3

VARISTER

33

TR

TR

ANSFORMER

34

EKD

DRIVER MODULE -E

TS

35

EC

EC

ONOMIZER SOLENOID

VAL

VE

36

PB

EMERGERNCY ST

OP SWIT

CH

120

OUT

C0

Y0

Y1

Y2

Y3

Y7

Y6

Y5

DVP

-08SN

Y4

224

225

226

CO

M

D24

1C

1B

1A

TE01

2C

2B

2A

TE02

3C

3B

3A

4C

4B

4A

5C

5B

5A

TE05

CO

M

D24

CO

M

D24

24V

G

.

CH1

FG

I-

L-

DVP

-04PT

L+

FG

I-

L-

L+

.

L+

L-

I-

FG

L+

L-

I-

FG

CH2

CH3

CH4

0V

24V

G

.

CH1

FG

I-

L-

DVP

-04PT

L+

FG

I-

L-

L+

.

L+

L-

I-

FG

L+

L-

I-

FG

CH2

CH3

CH4

0V

CO

M

D24

E

+

-

EP

AI1

+

-

CP

AI2

7

8

AI3

G

IT

AO

1

AC

O

M

TO EKD

DVP

-06X

A

CH1

CO

M

I+

V+

0V

24V

G

CO

M

I+

V+

CH2

CO

M

I+

V+

CH3

CO

M

I+

V+

CO

M

I+

V+

CO

M

I+

V+

CH4

CH5

CH6

D24

CO

M

302

303

303

302

301

R2

R2

R2

KM1

KM3

KM2

231

232

230

231

232

230

231

232

230

-

DVP

-12SA

IN

0V

24V

G

OUT

S/S

C0

X0

X1

X2

X3

Y0

C1

RS

-485

+

X4

X5

X6

X7

Y1

C2

Y2

Y3

227

KM1

KM2

KM3

EC

PY

SV1

SV3

SV2

AC220/24V

TR

R23

T23

R21

T21

F2/1A

R33

20V

A

TO ELEC.EXP

.V

AL

VE (E

TS)

501

502

503

504

302

303

301

301

EKD

24V

AC

-

1

2

5

6

7

8

ET

S

21

22

24

25

26

+

20

FROM PL

C

D24

120

CH

AO

1

AC

OM

410

TO PL

C

TE03

TE04

230

231

232

233

233

233

233

E

E

FOR CHW PUMP

STAR

T/STOP SGL

FOR COMPRESSOR

RUN/STOP INDIC

ATION

FOR FAUL

T

INDICATION

FOR FAUL

T

INDICATION

TO USER'S MC

C

FOR CHW PUMP

INTERLOCK

FOR REMOTE

STAR

T/STOP SGL

FOR REMOTE

RESTAR

T SGL

FROM USER'S MC

C

CONTROL PNL

ST

AR

TER PNL

BOD

Y

WIRING

POWER

CTRL. P

ANEL

ABNORM

AL SGL

MO

TOR&POWER

TR

ANSDUCER SGL

CURRENT

FROM ST

AR

TER P

ANEL

CONT

AC

TOR SIGNAL

COOLING F

ANS RUN/ST

OP

TO ST

AR

TER P

ANEL

FANS RUN SGL

NO

TE

SUPPLIED B

Y USERS

LOC

ATED ON CHILLER BOD

Y

FROM/T

O ST

AR

TER P

ANEL

FROM/T

O USER'S MC

C

R2

R02

R2

R02

R2

R02

PB

ST

OP SGL

EMERGERNCY

11

14

12

L2 L3

L1

VP

-A

AZ

AY

AX

AW

AV

AU

R2

PB

R2

T2

380V

TR

R02

T2

220V

R01

T01

NFB2

10A

S-A

2M

-A

1M

-A

S-A

2M

-A

161

2M

158

1M

S

AT

1

AS1

AR1

600V

NFB1-

A

301

302

303

-A

88F1

AU

1

FM

1

KM1

KM2

KM3

-A

-A

-A

-A

-A

-A

-A

S-B

2M

-B

171

2M

168

1M

S

304

305

306

KM1

KM2

KM3

-B

-B

-B

-B

-B

-B

AU

AV

AW

106

D24

T2

R2

M2

M1

N

L

L1

M

P-

A

L3

L2

BU

BV

BW

123

D24

T2

R2

M2

M1

N

L

L1

MP

-B

L3

L2

FAN

88F 1-A

230

323

321

51F1

51F3

-A

-A

88F 3-A

88F 5-A

232

326

325

51F5

51F6

-A

-A

88F 6-A

88F 1-B

329

327

51F1

51F3

-B

-B

88F 3-B

88F 5-B

51F5

51F6

-B

-B

88F 6-B

231

233

244

246

245

247

T2

AT

0

AS0

AR0

D24

107

A

BZ

BY

BX

BW

BV

BU

S-B

2M

-B

1M

-B

BT

1

BS1

BR1

600V

NFB1-B

B

BT

0

BS0

BR0

VP

-B

D24

124

11

14

12

L2 L3

L1

-A

51F1

AV

1

AW

1

-A

88F2

AU

2

FM

2

-A

-A

51F2

AV

2

AW

2

-A

88F3

AU

3

FM

3

-A

-A

51F3

AV

3

AW

3

-A

88F4

AU

4

FM

4

-A

-A

51F4

AV

4

AW

4

C

OMP

MO

TOR

-B

88F1

BU1

FM

1

-B

-B

51F1

BV1

BW1

-B

88F2

BU2

FM

2

-B

-B

51F2

BV2

BW2

-B

88F3

BU3

FM

3

-B

-B

51F3

BV3

BW3

-B

88F4

BU4

FM

4

-B

-B

51F4

BV4

BW4

C

OMP MO

TOR

T2

T2

T2

R2

R2

302

303

106

302

303

303

302

301

R2

R2

R2

231

232

KM1

KM3

KM2

233

-A

-A

-A

MP

301

301

230

231

232

233

230

231

232

233

230

-A

-A

VP

107

D24

106

107

D24

E

R2

R02

R02

R02

R2

R2

R2

AIG

AIG

AIG

AI5

AI5

AI5

305

306

123

305

306

306

305

304

R2

R2

R2

245

246

KM1

KM3

KM2

247

-B

-B

-B

MP

304

304

244

245

246

247

244

245

246

247

244

-B

-B

VP

124

D24

123

124

D24

E

AIG

AIG

AIG

AI6

AI6

AI6

AC

2

AC

1

R2

G

IT

-A

CT

-A

AI5

T2

BC2

BC1

R2

G

IT

-B

CT

-B

AI6

T2

3PH 380V

AC 50/60HZ

M

AIN POWER SUPPL

Y

3PH 380V

AC 50/60HZ

M

AIN POWER SUPPL

Y

TO C

ONTROL

PANEL

3. FROM/T

O C

ONTROL P

ANEL.

2.

THESE P

AR

TS ARE L

OC

ATED ON CHILLER BOD

Y.

Not

e

1.

THESE P

AR

TS ARE L

OC

ATED IN C

ONTROL P

ANEL.

ST

AR

TER PNL

CONTROL PNL

BOD

Y

WIRING

ST

OP SGL.

EMERGERNCY

ABNORM

AL SGL

-A

MO

TOR&POWER

TR

ANSDUCER SGL.

CURRENT

-A

POWER

CTRL. P

ANEL

TO C

ONTROL P

ANEL

CONT

AC

TOR SIGNAL

-A

COOLING F

ANS SIGAL

-A

FROM C

ONTROL P

ANEL

ST

AR

TER PNL

CONTROL PNL

BOD

Y

WIRING

ABNORM

AL SGL

-B

MO

TOR&POWER

TR

ANSDUCER SGL.

CURRENT

-B

TO C

ONTROL P

ANEL

CONT

AC

TOR SIGNAL

-B

COOLING F

ANS SIGAL

-B

FROM C

ONTROL P

ANEL

ELEC

TRIC

AL P

AR

T LIST

1

1M,2M,S

M

AGNE

TIC C

ONT

AC

TOR

2

NFB1

MOLDED C

ASED CIRCUIT

BREAKER

3

NFB2

NO FUSE BREAKER

4

TR

TR

ANSFORMER

700V

A

5

PB

EMERGERNCY ST

OP SWIT

CH

6

MP

MO

TOR PRO

TEC

T RELA

Y

7

VP

POWER PRO

TEC

TOR

8

IT

AMPERE

TR

ANSDUCER

9

CT

CURRENT

TR

ANSFORMER

10

88F1-6

M

AGNE

TIC C

ONT

AC

TOR

11

51F1-6

THERM

AL RELA

Y

12

FM1-6

COOLING F

AN

13

FA

N

COOLING F

AN

14

KM1-3

AUX.RELA

Y C

ONT

AC

T

FROM C

ONTROL

PNL

1

4

3

2

5

6

1

4

3

2

5

6

-A

88F5

AU

5

FM

5

-A

-A

51F5

AV

5

AW

5

-A

88F6

AU

6

FM

6

-A

-A

51F6

AV

6

AW

6

-B

88F5

BU5

FM

5

-B

-B

51F5

BV5

BW5

-B

88F6

BU6

FM

6

-B

-B

51F6

BV6

BW6

88F 2-A

322

51F2 -A

324

51F4 -A

88F 4-A

328

51F2 -B

88F 2-B

51F4 -B

88F 4-B

330

331

332

LS

Air-Cooled Water Chillers

20