Summary of Contents for RCI-1502 LM

Page 2: ......

Page 53: ...Appendix 8 1 Data Logging on RCI Systems ...

Page 54: ......

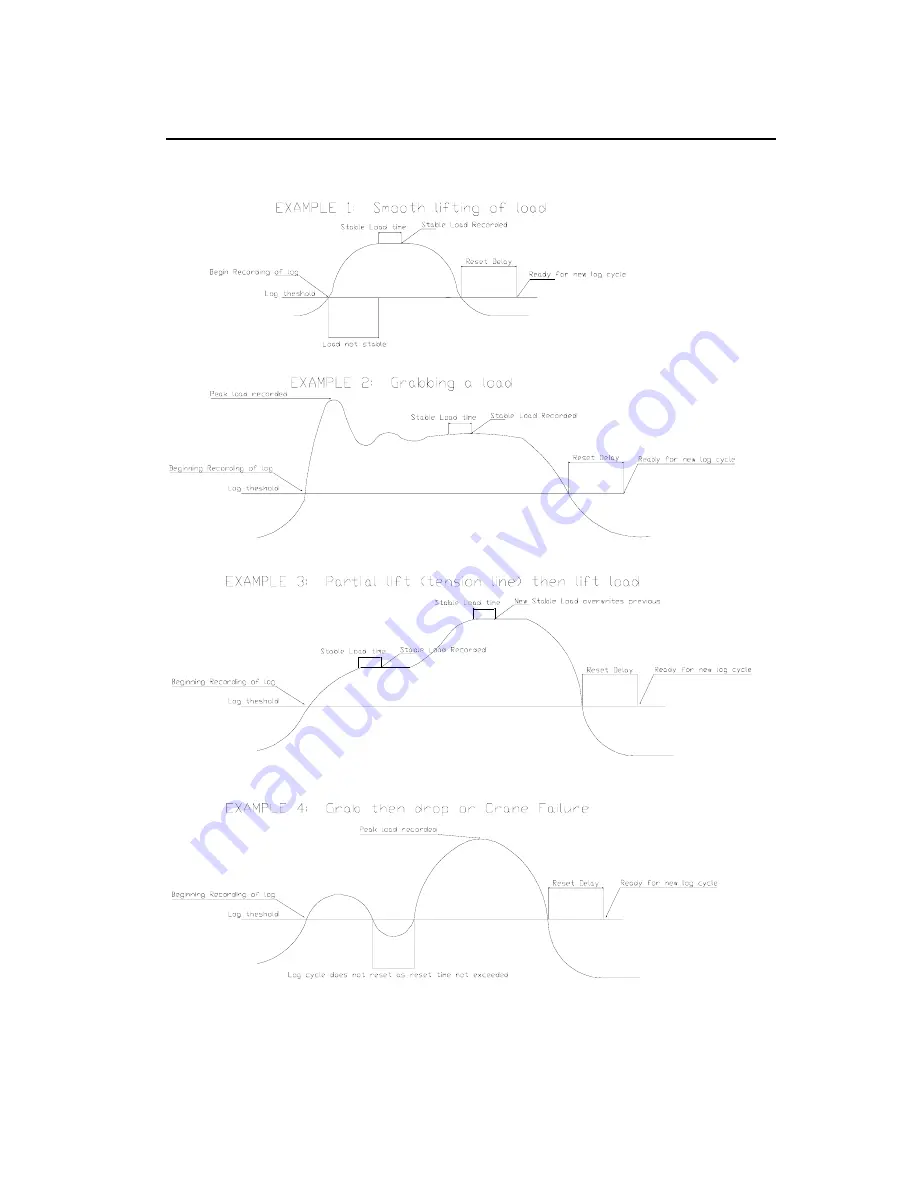

Page 60: ...Data Logging on RCI Systems Example Lift Cycles ...

Page 65: ...Appendix 8 2 Drawings ...

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 71: ...U N C O N T R O L L E D C O P Y ...

Page 72: ...APPROVED BY TOL 0 0 0 1 2 3 4 55 26 2 0 7 2 8 9 1 1 1 1 0 7 5 6 2 ...

Page 73: ......

Page 74: ...APPROVED BY TOL 0 0 0 1 22 3 4 5 6 0 22 2 1 7 8 98 1 7 8 98 7 8 98 7 8 98 1 0 9 8 3 6 8 3 ...

Page 75: ......

Page 76: ... APPROVED BY 0 1 2 22 3 3 3 TOL 4 4 23 4 232 22 3 242 4 2 32 2 3516 7 8 7 7 9 2 3 42 4 2 ...

Page 77: ......

Page 78: ... APPROVED BY 0 1 2 22 3 3 3 TOL 4 4 23 4 232 22 5 0 42 4 2 3617 8 9 8 8 2 ...

Page 79: ......

Page 80: ......

Page 84: ......

Page 85: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......