Learning Advanced Features

198

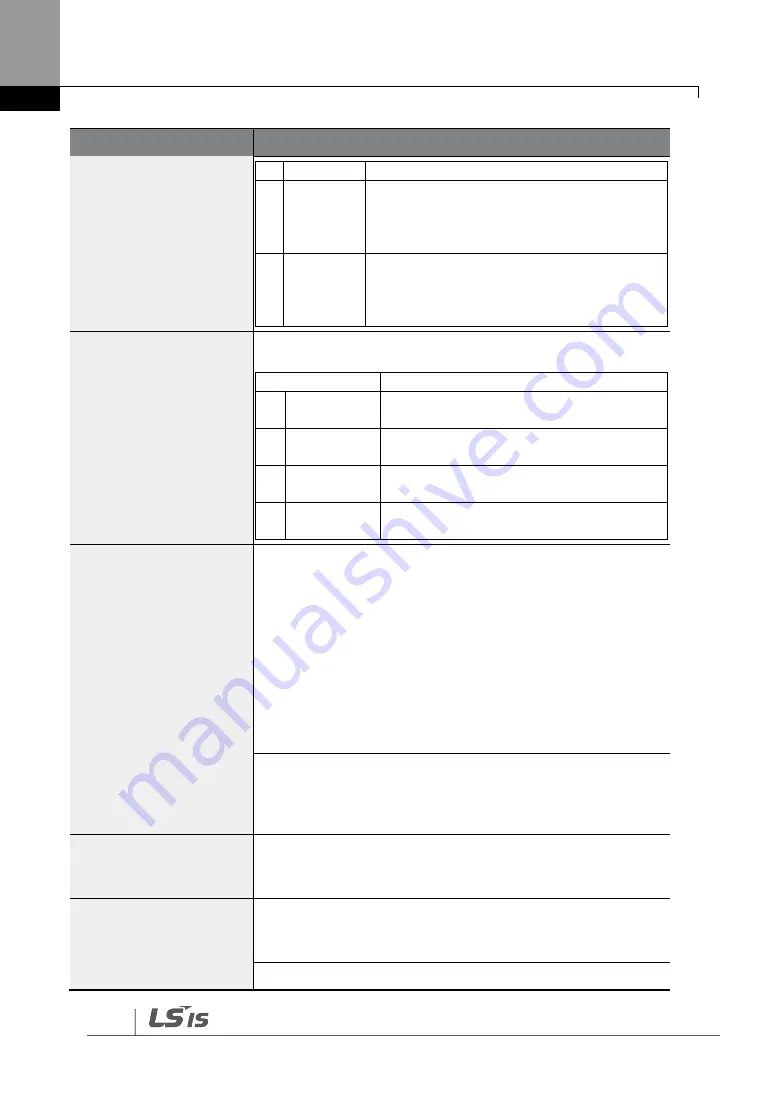

Code

Description

operation by turning on the terminal.

2

Power

Performs a pump clean operation when a

pump consumes more power than it is

supposed to consume in a normal

operation.

3

Current

Performs a pump clean operation when a

pump consumes more current than it is

supposed to consume in a normal

operation.

AP2-16 PumpClean Sel

Sets the pump clean start mode.

Setting

Function

0

None

Pump clean is performed only by the

function set at AP2-20.

1

Start

Pump clean is performed each time the

inverter starts operating.

2

Stop

Pump clean is performed each time the

inverter stops operating.

3

Start &

Stop

Pump clean is performed each time the

inverter starts or stops operating.

AP2-17 PC Curve Rate

AP2-18 PC Curve Band

AP2-19 PC Curve DT

If AP2-

15 is set to ‗Power‘ or ‗Current,‘ multiply the load

characteristic curve set at AP2-2

–AP2-10 by the value set at

AP2-17 (100[%]+AP2-17[%]), and reset the load

characteristic curve for the pump clean operation (refer to the

load tune features for AP2-2

–AP2-10 setting values).

Apply (rated inverter current x AP2-18 setting value) and

(rated motor x AP2-18 setting value) to the pump clean load

curve calculated by AP2-17 to calculate the final pump clean

load curve.

The inverter performs pump clean operation when the

inverter continues operating for the time set at AP2-19.

AP2-20 Clean Start DT

When AP2-

15 is set to ‗Power‘ or ‗Current‘, a pump clean is

performed if the inverter operation power or current stays

above the pump clean load characteristic curve (defined by

AP2-17 and AP2-18) for the time set at AP2-19.

AP2-21 Clean Step DT

Sets the time for the inverter to maintain 0 speed (stop)

before the inverter switches from forward to reverse operation

during a pump clean.

AP2-22 PumpClean AccT

AP2-23 PumpClean

DecT

Sets the Acc/Dec times for pump clean operations.

AP2-24 Fwd Steady Time Sets the time to maintain forward and reverse operations.

Summary of Contents for H100

Page 14: ......

Page 18: ...Preparing the Installation 4 37 90 kW 3 Phase ...

Page 27: ...Preparing the Installation 13 ...

Page 47: ...33 Installing the Inverter ...

Page 48: ...Installing the Inverter 34 Input and Output Control Terminal Block Wiring Diagram ...

Page 61: ...47 Installing the Inverter ...

Page 71: ...Learning to Perform Basic Operations 57 ...

Page 88: ...Learning to Perform Basic Operations 74 ...

Page 103: ...89 Learning Basic Features Code Description V1 Quantizing ...

Page 129: ...115 Learning Basic Features ...

Page 140: ...Learning Basic Features 126 ...

Page 148: ...Learning Basic Features 134 ...

Page 171: ...157 Learning Advanced Features Deceleration dwell operation ...

Page 183: ...169 Learning Advanced Features ...

Page 184: ...Learning Advanced Features 170 PID Command Block ...

Page 185: ...171 Learning Advanced Features PID Feedback Block ...

Page 186: ...Learning Advanced Features 172 PID Output Block ...

Page 187: ...173 Learning Advanced Features PID Output Mode Block ...

Page 197: ...183 Learning Advanced Features ...

Page 201: ...187 Learning Advanced Features Code Description 100 EPID1 Control block ...

Page 202: ...Learning Advanced Features 188 EPID2 Control block ...

Page 237: ...223 Learning Advanced Features Time Period Schedule AP3 38 Except3 Day 01 01 ...

Page 244: ...Learning Advanced Features 230 ...

Page 259: ...245 Learning Advanced Features Code Description Code Description Volt ...

Page 362: ...Learning Protection Features 348 ...

Page 415: ...401 RS 485 Communication Features Item Standards Parity check None ...

Page 524: ...Table of Functions 510 ...

Page 533: ...Table of Functions 519 ...

Page 547: ...533 Troubleshooting ...

Page 585: ...Technical Specification 571 ...

Page 594: ...580 ...

Page 595: ...581 ...

Page 596: ...582 ...