Learning Basic Features

80

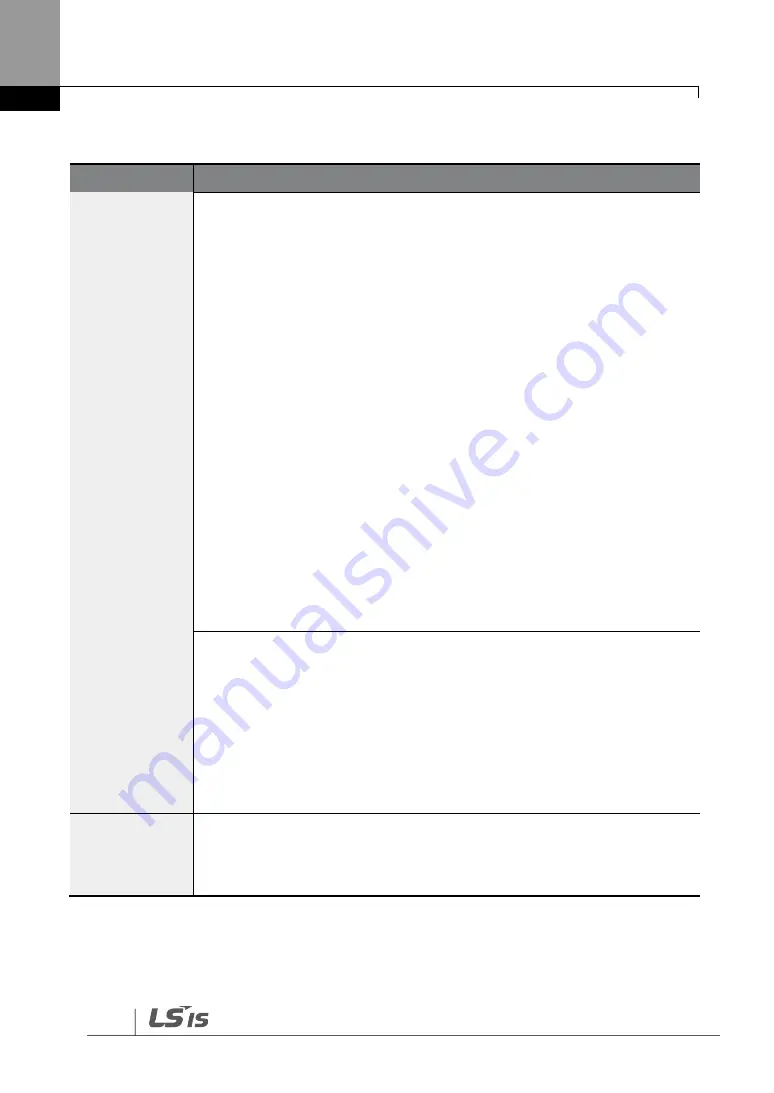

Basic HAND/AUTO/OFF Mode Operations

Mode

Description

HAND Mode

(Locally

controlled

operation mode)

In HAND mode, operation is available only by the keypad input. In Monitor

mode, the currently set frequency reference is displayed at all times.

Also, in HAND mode:

•

The first monitoring item is used to adjust the frequency with the

up/down and left/right keys. The set frequency is refelected in DRV-02

(HAND Cmd Freq).

•

The motor‘s rotation direction can be set at DRV-02 (Keypad Run Dir).

•

Terminal block functions do not operate (with the exception of BX,

External Trip, and multi-step acc/dec operation related terminal

functions).

•

Fire mode commands take the highest priority (if any are given).

•

The following advanced features are not available:

-

PID / EPID control

-

Flow compensation

-

Pump clean

-

Load tuning

-

Motor preheating

-

Time scheduling

-

PowerOn resume

-

Multiple motor control

•

Inverter monitoring and protection features are available in HAND

mode.

OFF Mode

(Standby)

In OFF mode, the inverter operation stops. Pressing the OFF key during

HAND/AUTO mode operations will cause the OFF LED to turn on. Then,

the inverter stops operating or decelerates and stops, according to the

deceleration options set by the user.

Also, in AUTO mode:

•

Terminal block functions do not operate (with the exception of BX,

External Trip and multi-step acc/dec operation related terminal

functions).

•

Fire mode commands take the highest priority (if any are given).

AUTO Mode

(Remotely

controlled

operation mode)

In AUTO mode, the inverter operates based on the command from the

command source set at DRV-06 (Cmd Source), with the frequency

reference from the source set at DRV-07 (Freq Ref Src).

Summary of Contents for H100

Page 14: ......

Page 18: ...Preparing the Installation 4 37 90 kW 3 Phase ...

Page 27: ...Preparing the Installation 13 ...

Page 47: ...33 Installing the Inverter ...

Page 48: ...Installing the Inverter 34 Input and Output Control Terminal Block Wiring Diagram ...

Page 61: ...47 Installing the Inverter ...

Page 71: ...Learning to Perform Basic Operations 57 ...

Page 88: ...Learning to Perform Basic Operations 74 ...

Page 103: ...89 Learning Basic Features Code Description V1 Quantizing ...

Page 129: ...115 Learning Basic Features ...

Page 140: ...Learning Basic Features 126 ...

Page 148: ...Learning Basic Features 134 ...

Page 171: ...157 Learning Advanced Features Deceleration dwell operation ...

Page 183: ...169 Learning Advanced Features ...

Page 184: ...Learning Advanced Features 170 PID Command Block ...

Page 185: ...171 Learning Advanced Features PID Feedback Block ...

Page 186: ...Learning Advanced Features 172 PID Output Block ...

Page 187: ...173 Learning Advanced Features PID Output Mode Block ...

Page 197: ...183 Learning Advanced Features ...

Page 201: ...187 Learning Advanced Features Code Description 100 EPID1 Control block ...

Page 202: ...Learning Advanced Features 188 EPID2 Control block ...

Page 237: ...223 Learning Advanced Features Time Period Schedule AP3 38 Except3 Day 01 01 ...

Page 244: ...Learning Advanced Features 230 ...

Page 259: ...245 Learning Advanced Features Code Description Code Description Volt ...

Page 362: ...Learning Protection Features 348 ...

Page 415: ...401 RS 485 Communication Features Item Standards Parity check None ...

Page 524: ...Table of Functions 510 ...

Page 533: ...Table of Functions 519 ...

Page 547: ...533 Troubleshooting ...

Page 585: ...Technical Specification 571 ...

Page 594: ...580 ...

Page 595: ...581 ...

Page 596: ...582 ...