Lucent Technologies Lineage

®

2000 ECS Battery Plant H569-416

Issue 2 August 1996

Product Description 2 - 5

The ECS battery plant is designed as a totally integrated energy

system package in which modular front-access design facilitates

installation and growth. One standard equipment bay will

accommodate a maximum of 12 Lineage

®

2000 SR Series -48-

volt, 50-ampere rectifiers, a Lineage

®

2000 ECS controller,

standard distribution panels accepting breakers from 3 to 60

amperes, and an optional low voltage battery disconnect/

reconnect feature. Style strips are an optional appearance kit.

Rectifier

The Lineage

®

2000 SR Series rectifiers are designed specifically

for applications where small size, low weight and ease of

installation are of overriding importance. The rectifiers utilize a

combination of switch-mode technology and forced air cooling

to achieve a significant reduction in size and weight over

conventional ferroresonant rectifiers. The plug in, connectorized

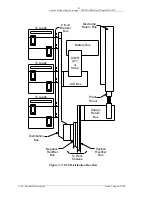

Figure 2-2: Typical ECS Battery Plant System Block Diagram

RECTIFIER

A/C

RECTIFIER

BATTERY

STRING

BATTERY

STRING

BATTERY

BUS

LVD

TO OFFICE

ALARMS

LINEAGE 2000

ECS

FOR ESD WRIST STRAP

CHARGE

RETURN BUS

1200 A

SHUNT

DISCHARGE

RETURN BUS

DISTRIBUTION

TO OFFICE

LOADS

CHARGE

BUS

ALARMS

OUTPUT

VOLTS

AMPS

FLOAT

EQ

BD

ACF

MNF

EO

MJF

RFA

µP

SWI

NORM

V

Lucent