Power failure

....................................................................................................................................................................................................................................

Overview

The procedures described below should be performed if the subrack

powering procedure was unsuccessful.

Procedure 1 should be used if the measured voltage at the termination

blocks of the PDP does not lie between -40.5 and -72 V.

Procedure 2 should be used if the PWR ON LED does not light up on

the user panel.

Procedure 3 should be used if the PWR ON LED does not light up on

the fan unit.

Procedure 1

Follow the steps below if the measured voltage at the termination

blocks of the PDP does not lie between -40.5 and -72 V:

............................................................................................................................................................

1

Switch off the external battery.

............................................................................................................................................................

2

Replace all affected power supply lines between the external battery

and the termination blocks of the PDP. Make sure the cables are tight

afterwards.

..........................................................................................................................................................

3

Switch on the external battery.

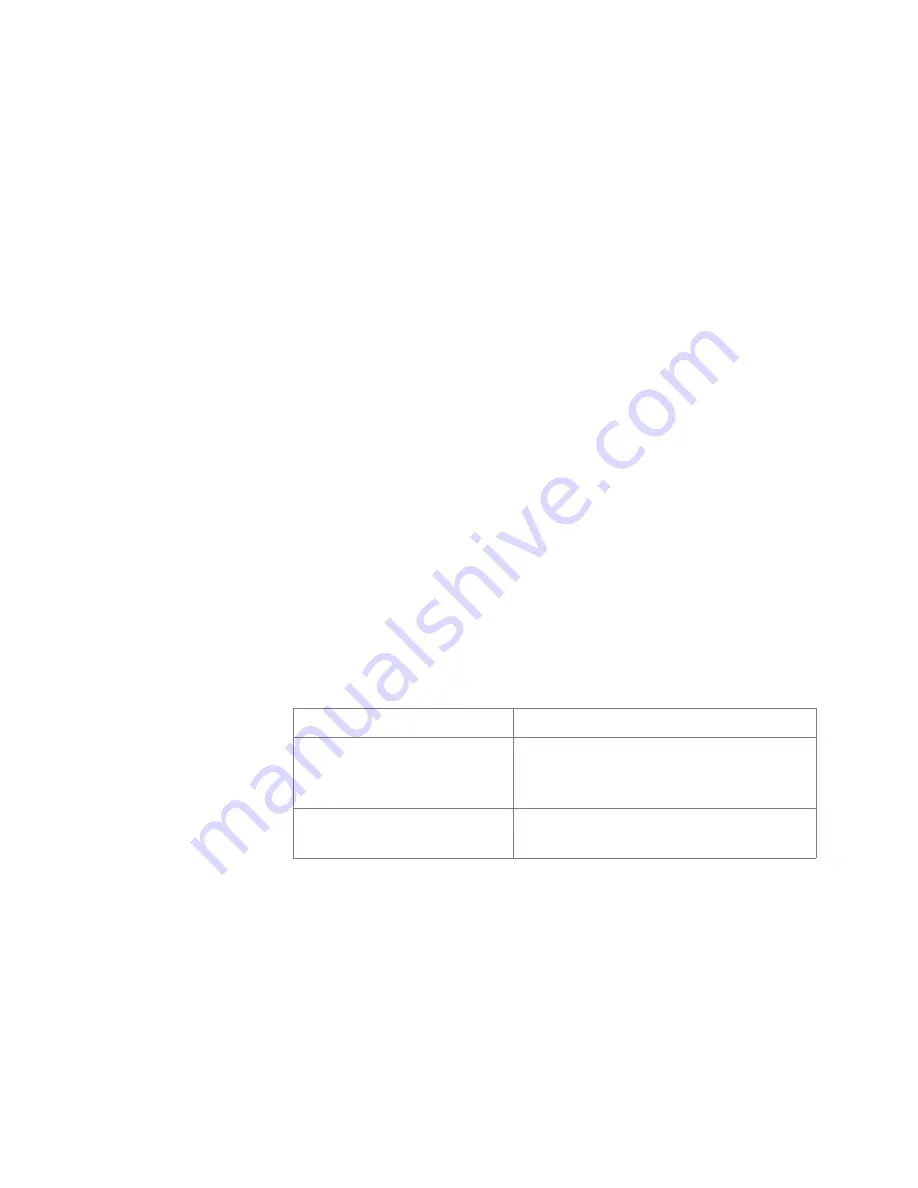

IF ...

THEN ...

the measured voltage does

not lie between -40.5 and

-72 V,

check the external battery.

the measured voltage lies

between -40.5 and -72 V,

END OF STEPS

Installation trouble shooting

....................................................................................................................................................................................................................................

A - 2

Lucent Technologies

365-374-074

Issue a, April 2002

E

N D

O F

S

T E P S

............................................................................................................................................................