Lucent Technologies Lineage

®

2000 100A Ferroresonant Rectifier J85503A-1

8 - 10 Spare Parts and Replacement Procedures

Issue 6 October 1998

•

All removal and replacement procedures are easier to

perform on bay-mounted rectifiers that have been removed

from the bay.

•

Most component removals are straightforward and obvious.

Therefore, these procedures can be used as a guide by

qualified service personnel, rather than as step-by-step

procedures. For example, you may prefer to remove a part

not called for in order to make more room for access to a

component being replaced.

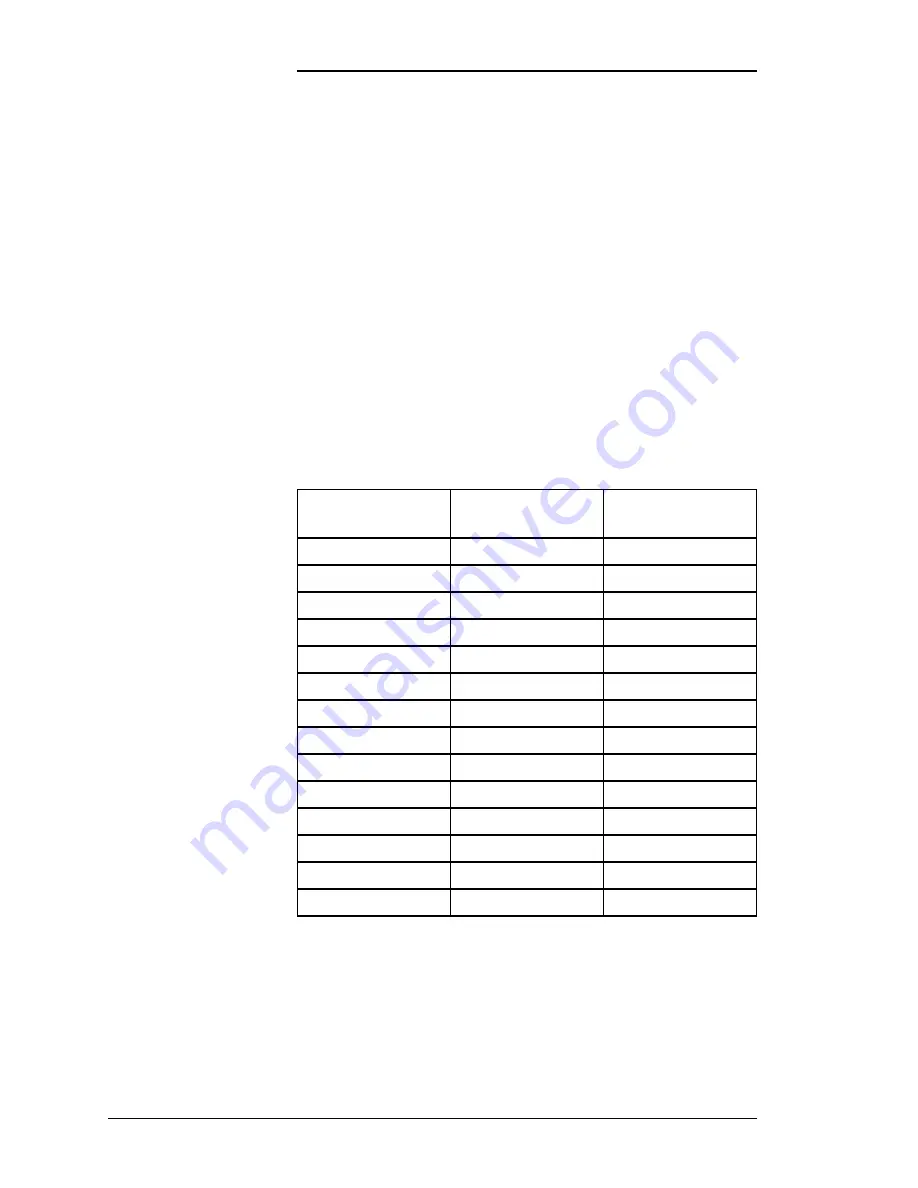

Table 8-D and Table 8-E provide the reassembly torquing

requirements for the electrical and mechanical connections in

the rectifier. Use these values unless otherwise directed in the

procedures.

Table 8-D: Torque and Minimum Yield Strength for

Mechanical Connections (Using Hex Head Cap Screws)

Cap Screw

Diameter (inches)

Min. Yield

Strength (PSI)

Torque (Ft-Lb)

UNC

1/4

57,000

6

5/16

57,000

12

3/8

57,000

22

7/16

57,000

35

1/2

57,000

54

9/16

57,000

77

5/8

57,000

107

3/4

57,000

190

7/8

36,000

193

1

36,000

290

1-1/8

36,000

410

1-1/4

36,000

580

1-3/8

36,000

760

1-1/2

36,000

1010