5

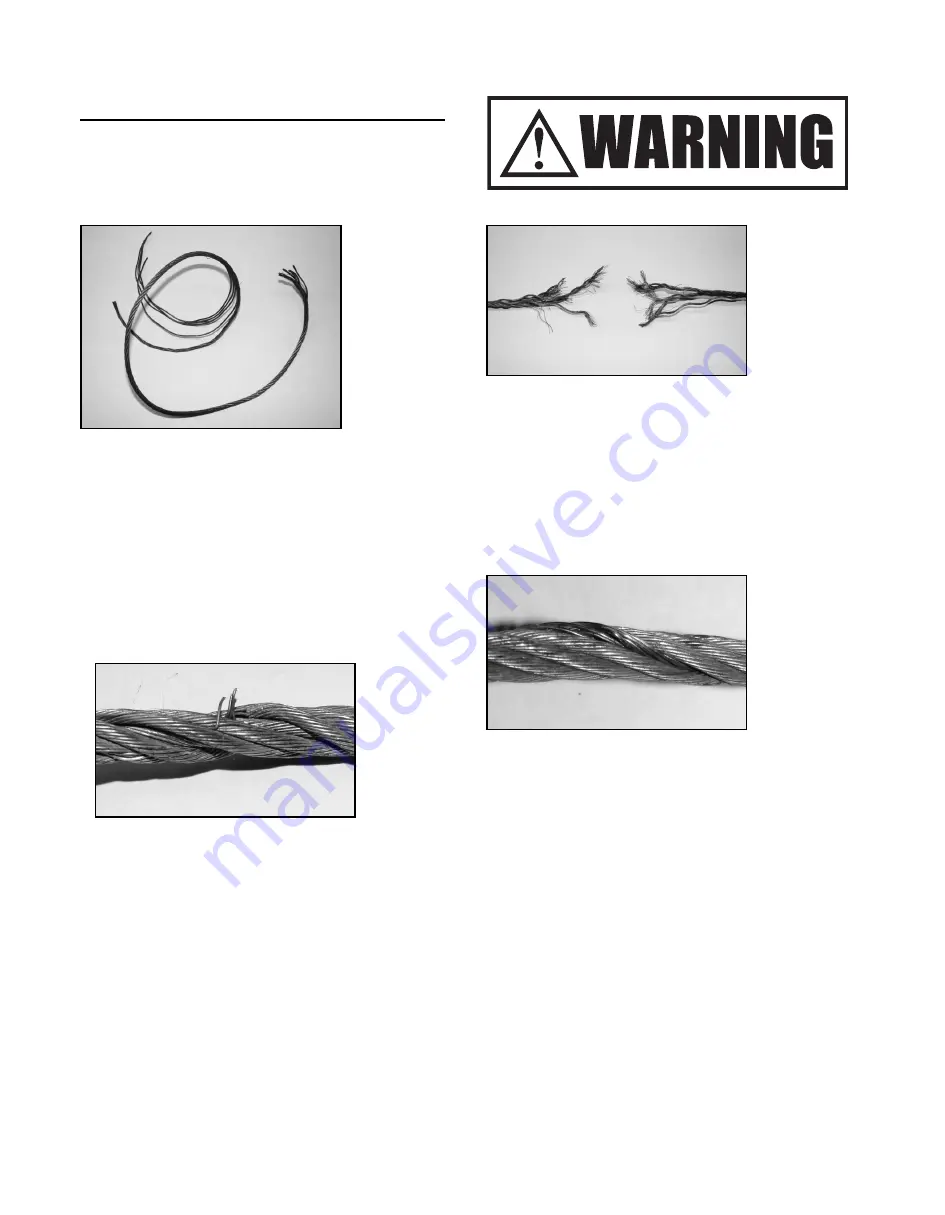

Broken Wires

The frayed condition of this cable indicates

broken wires and an unsafe condition. Cable

deficiencies of this type are usually caused by

abrasion. This can easily happen in a hoist

operation if the operator allows the cable to

come in contact with any other surface. This

cable is considerably weakened and must be

replaced before the hoist can be safely

operated.

Kinks

Kinks can result from improper uncoiling and

unspooling, or they can be formed in hoist

operation. Cable loops can occur in a slack

line, or in a line under tension. If a loop

occurs, it should be removed immediately.

Otherwise the loop may be pulled through

when tension is applied to the line and form a

permanently deforming kink. Kinks in a cable

are always dangerous as they create unequal

tension in the rope and in the strands. A cable

with kinks must be replaced before the hoist

can be safely operated.

DAILY CABLE INSPECTIONS

Drum Crushing and Spiraling

The badly deteriorated condition of this cable

clearly indicates that it is unsafe for operation.

Cable damage of this type is usually caused by

hoist abuse and by repeatedly overloading the

hoist beyond its rated capacity. A hoist with this

cable condition should not be used under any

circumstances, and the cable must be replaced

before the hoist can be safely operated.

Cut Cable

The condition of this cable indicates that it has

been cut by a sharp object. This is apparent to the

eye because several of the strands appear to be of

equal length. It goes without saying that this cable

must be replaced before the hoist can be safely

operated.

Operating Instructions For Your LUG-ALL® 6000-15 Cable Winch-Hoist / Copyright 2008 © LUG-ALL Corporation. All rights reserved.

The pictures below illustrate the more obvious

types of severely damaged cables. Cables

exhibiting damage of this sort to any degree must

be replaced immediately.