7

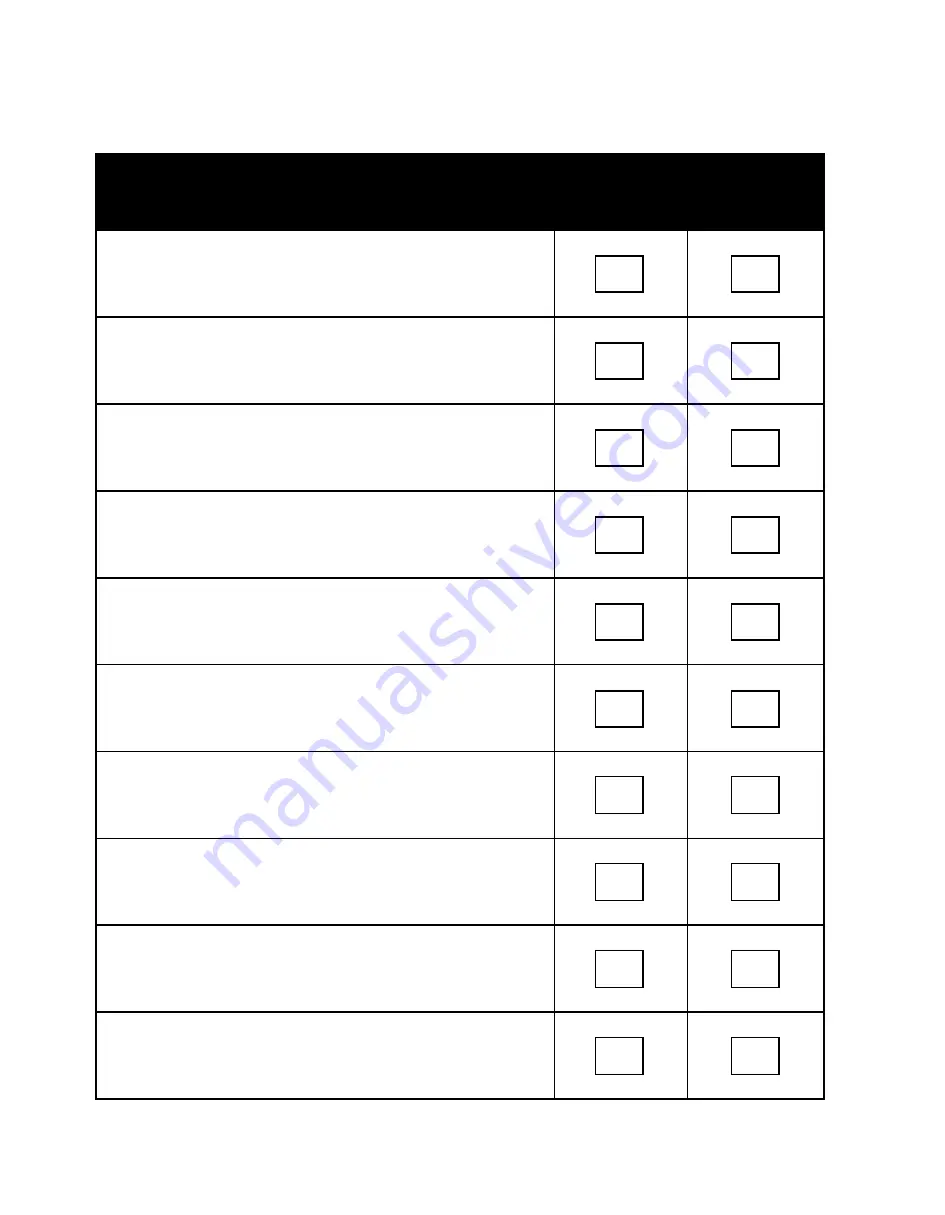

Cable Ratchet Winch-Hoist Pre-Operational Inspection

Unit Number: ___________________ Model: ____________________ Date: ____________________

Inspection Point

Inspection Result (

✓

)

Pass

Fail

1) Inspect hooks and latches for deformation, cracks, and

wear. An elongated or bent hook is an indication that the

hoist was overloaded.

2) Check operation of latches. Safety latches on the hooks

should not be defeated by wiring it open or by removal.

3) Inspect cable for kinks, cuts, broken strands, fraying or

abrasions.

4) Check ratchet teeth for gouges, burred edges or other

physical damage.

5) Check for bent or broken metal parts, rounded edges, and

elongated holes.

6) Check metal parts for corrosion.

7) Check pawls and levers for bends, cracks or other damage.

8) Check integrity of springs.

9) Operate U-frame and verify that the U-frame does not rub

against main frame during operation.

10) Test operating functions (lifting, lowering, free release)

of hoist.

NOTE: The cable should be pulled from the drum during inspection. The hoist should be removed from service if any inspection points fail.