25

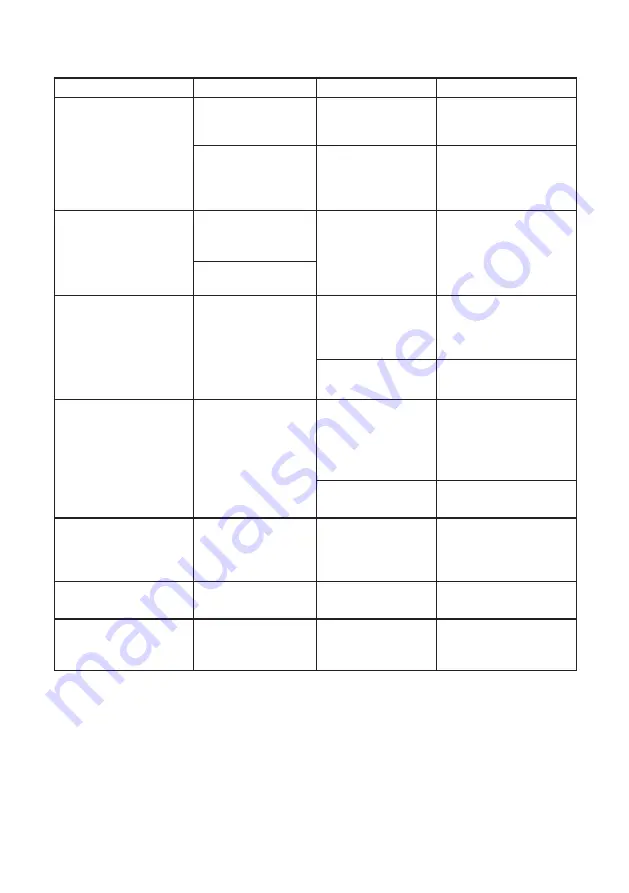

10. Troubleshooting

Trouble

Control

Cause

Solution

Equipment doesn’t

move when activated

Hose assemblies

connected

properly?

Hose assemblies

not connected

Reaffix hose

assemblies or re-

couple them

Does the pump

unit work?

Equipment or

hydraulic unit

defective

See separate

operating instructions

for hydraulic unit or

equipment.

Equipment

moves slowly or

jerkily when activated

Are the hoses

connected

correctly?

Air in the hydraulic

system

Deaerete hydraulic

system

Does the pump

unit work?

Pressure too high

(e.g. caused by

too-high ambient

temperature)

Set hydraulic pump

to pressureless

circulation

Coupling defective Coupling needs to be

replaced immediately

It is frequently not

possible to couple

hose assemblies

Control the

degree of viscosity

and application

temperature of

the used hydraulic

fluid

Hydraulic fluid

not adapted to

the application

situation

Hydraulic fluid

must be replaced

(see chapter

“Recommended

Hydraulic fluids”)

Coupling defective Coupling needs to be

replaced immediately

Damages of the

surface of the

hydraulic hoses

Mechanical

damages or

contact with

aggressive agents

Replace hoses

Leak in the couplings Is the coupling

damaged?

coupling damaged Coupling must be

replaced immediately

Hydraulic fluid leaking

from the hoses or

connections

Hoses defective?

Leak, possible

damage

Replace hoses

Summary of Contents for 81-60-10

Page 34: ...34 12 EC Declarations of conformity ...

Page 35: ...35 ...

Page 36: ...36 ...

Page 37: ...37 13 Notes ...

Page 38: ...38 ...

Page 39: ...39 ...