17.10.2008

Page 28

• AMIN 12-125T WH •

8

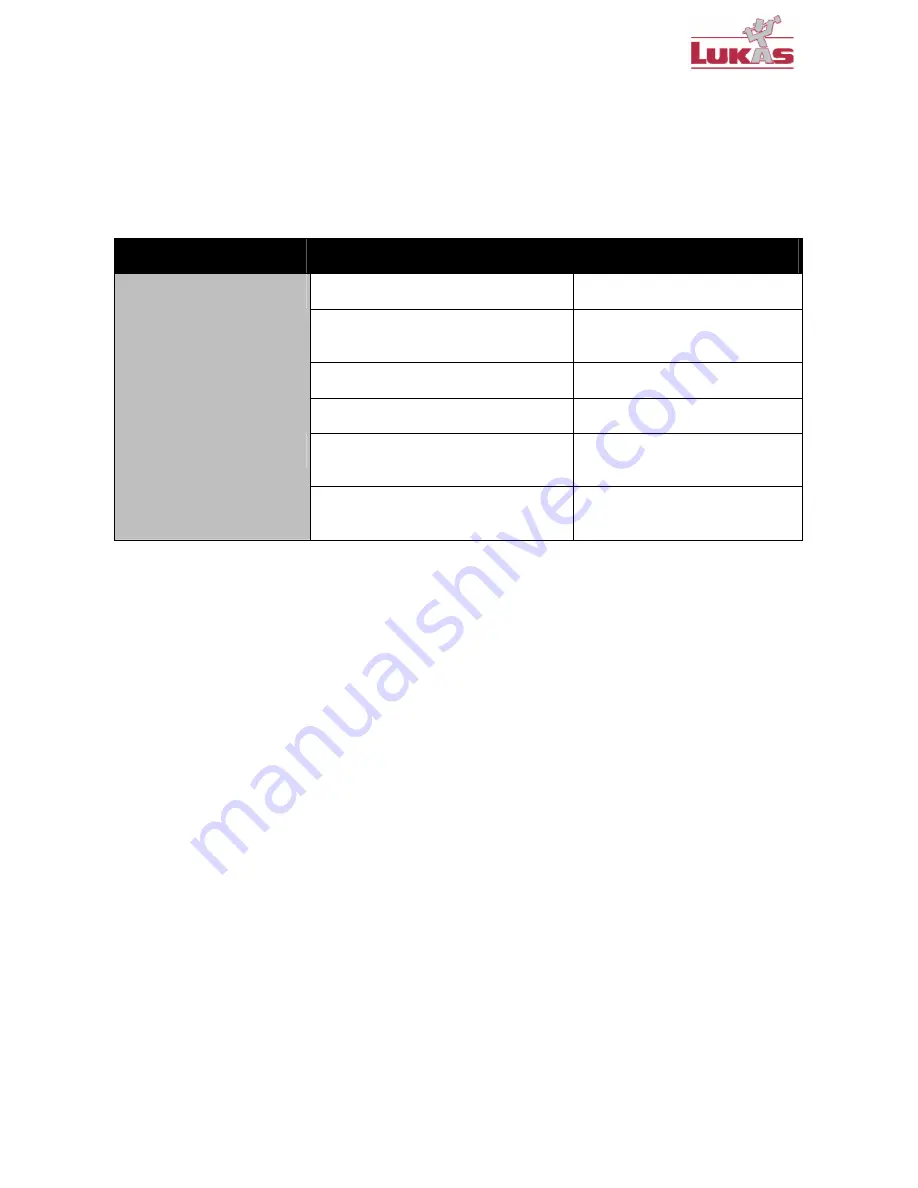

Help With Problems

If problems occur then follow the instructions given in this Technical Documentation regarding your

compliance and, if necessary, the corresponding action to be taken.

Possible problems and their causes are listed in the following table:

P

ROBLEM

C

AUSE

C

ORRECTION

Insufficient power

Operating pressure too low

Minimum flow pressure 6.3 bar

Choke point in the compressed air

line

Deal with any constricted

sections

Hose cross-section too small

Use the specified hose diameter

Screen holder dirty

Clean the screen holder

Machine does not start

No compressed air, cutoff valve

closed

Open the cutoff valve

Automatic overspeed protection was

triggered)*

Send the machine back to

LUKAS!

If necessary, send the machine to us.

)* How to check if the overspeed protection had been triggered:

1.

Disassemble the machine as described in section

Disassembly – Assembly

.

2.

Hold the motor 315177 E with the clamping jaws 460113 (included in the assembly tool set –

see

Accessories to Special Order

) in a vice.

3.

Completely undo the regulator 315176 B with the open-ended spanner SW 24 (right-hand

thread).

4.

Undo the 3 countersunk screws 830035 and remove the cover 315145.

5.

Check whether the piston 315143 has been deformed (see Fig.

Piston Comparison

).

6.

If the piston is deformed, send the machine back to us at once. Never operate the machine in

this state! Any manipulation of the piston can lead to the maximum speed being considerably

exceeded and hence could cause severe accidents!